High-strength RTV-2 sealant and preparation method thereof

A technology of RTV-2 and sealant, which is applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low product strength, influence of glue performance, high equipment requirements, etc., to improve production Efficiency and product quality, fast curing speed, good elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

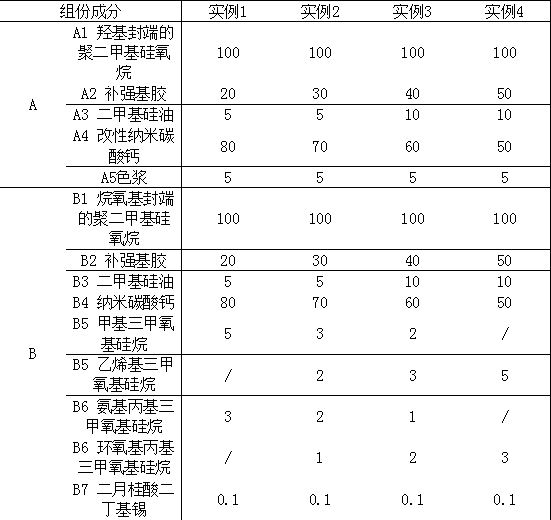

[0032] Prepare raw materials according to the ingredients and ratios shown in Standard 1 (the ratio of each component is the mass percentage), and prepare high-strength RTV-2 sealant according to the following method:

[0033] (1) Preparation of reinforcing base glue: Mix simethicone and fumed silica in a vacuum kneader evenly, then add silane coupling agent, first knead at below 100°C, and then set the temperature to 140°C ℃ for high temperature kneading treatment, the vacuum degree is -0.1Mpa, the kneading time is 5h, and then transferred to the three-roll machine for grinding for 2 times, and finally dispersed evenly in vacuum to obtain the reinforcing base rubber;

[0034] (2) Preparation of component A: Mix A1, A2, A4 and A5 evenly with a power mixer, the revolution speed is 20Hz, the dispersion speed is 20Hz, then control the temperature of the material to not exceed 100°C and stir for 2 hours; cool the material When the temperature is below 40°C, add A3 again, set the rev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com