Fuel cell cooling liquid suitable for low-temperature environment and preparation method thereof

A fuel cell and low-temperature environment technology, applied in the field of coolant, can solve problems such as increased electrical conductivity, accelerated corrosion of metal parts, and affecting the life of the coolant, achieving low electrical conductivity, hindering corrosion, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

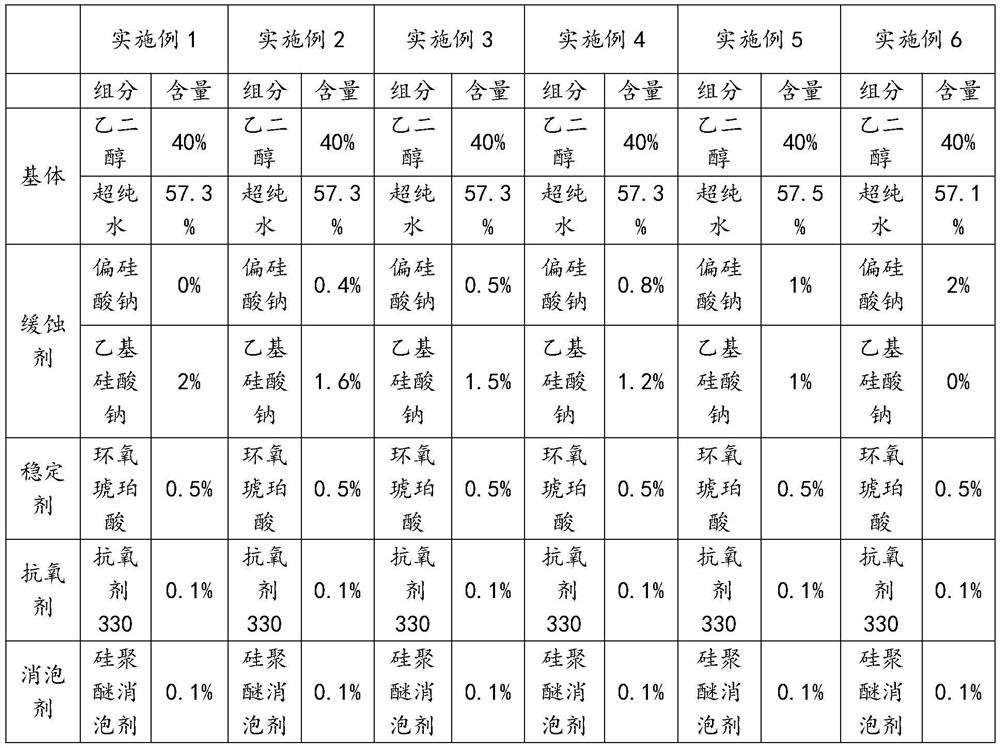

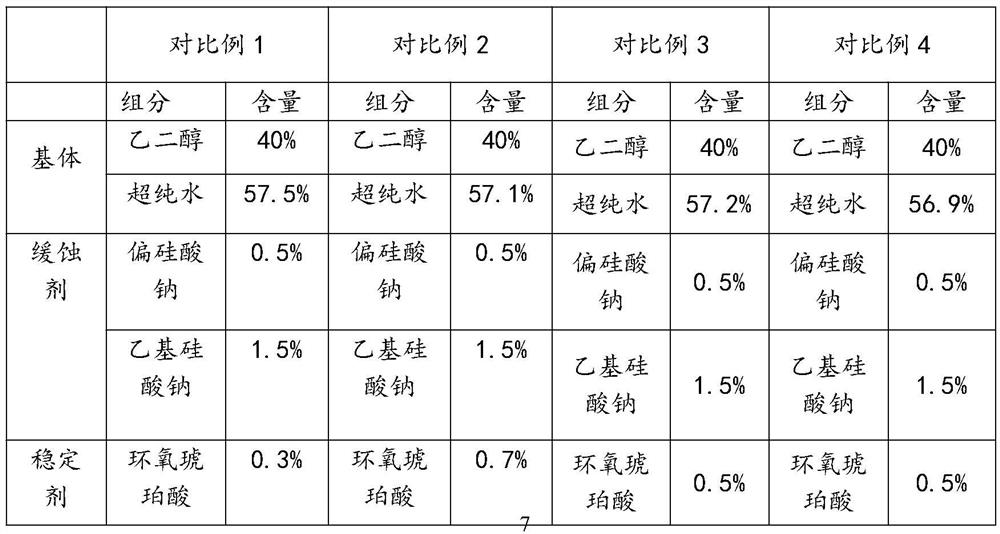

[0037] In Examples 1-6, the cooling liquid comprises 40% ultrapure water, 57.3% ethylene glycol, 2% corrosion inhibitor, 0.5% stabilizer, 0.1% antioxidant, 0.1% defoamer, wherein the corrosion inhibitor is Sodium metasilicate and sodium ethyl silicate, the stabilizer is epoxy succinic acid, the antioxidant is antioxidant 330, and the defoamer is silicon polyether defoamer.

[0038]The preparation method of the fuel cell coolant suitable for low-temperature environment in Examples 1-6 comprises the following steps:

[0039] S1: Divide ultrapure water into four equal parts, which are recorded as ultrapure water A, ultrapure water B, ultrapure water C and ultrapure water D;

[0040] S2: Dissolving the stabilizer and antioxidant in ultrapure water A at 60°C to obtain solution A;

[0041] S3: Dissolving the corrosion inhibitor in ultrapure water B at room temperature to obtain solution B;

[0042] S4: Dissolve the defoamer in ultrapure water C at room temperature, and stir evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com