High-flame-retardant polyurethane foam material for vehicle seat based on modified isocyanate

A technology of polyurethane foam and isocyanate, applied in the field of polyurethane materials, can solve the problems of strong plasticizing effect, poor physical properties, unsatisfactory flame retardant effect, etc., and achieves the effect of small combustion smoke and avoiding long-term effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

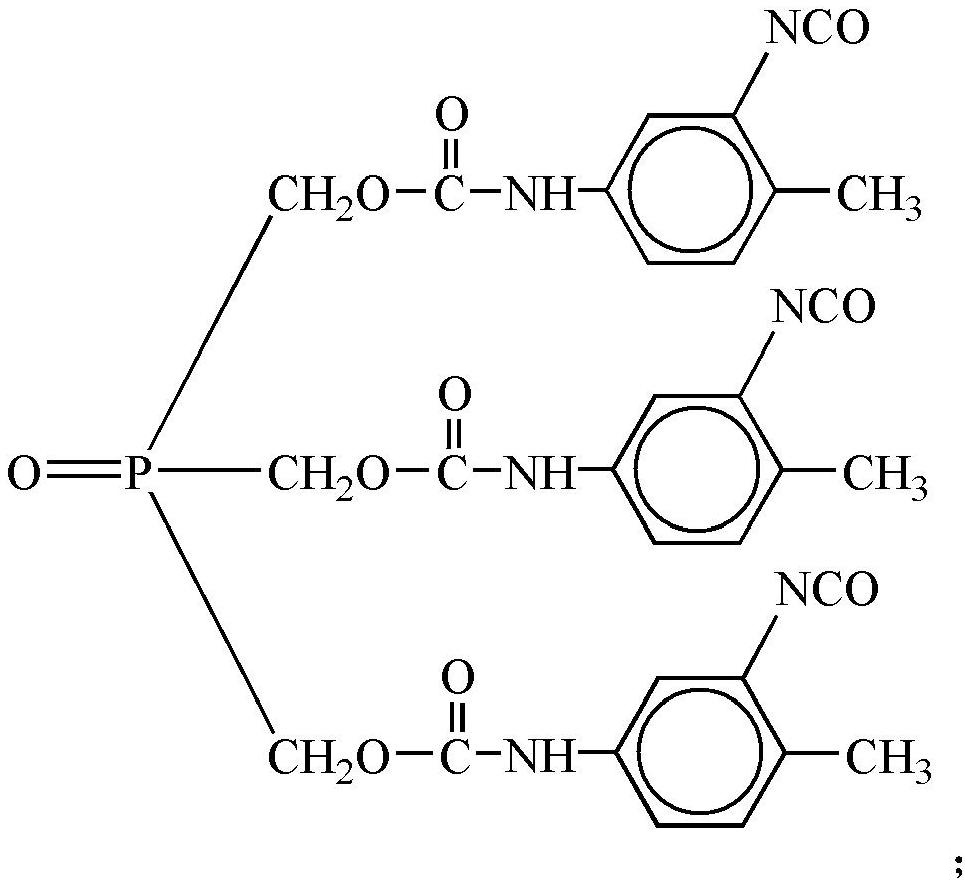

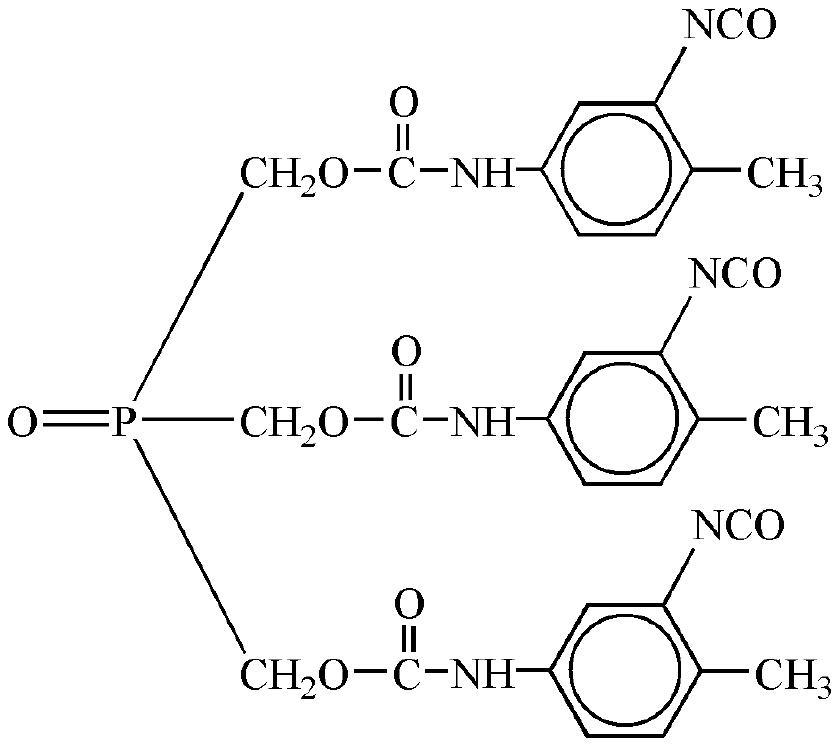

[0034] A highly flame-retardant polyurethane foam material for vehicle seats based on modified isocyanate that can solve the above-mentioned technical problems in this embodiment includes modified isocyanate and polyol, and the mass ratio of the two is (110-150) :100, the chemical structural formula of modified isocyanate is as follows:

[0035]

[0036] The P content of this modified isocyanate is 4.7%, the N content is 12.7%, and the NCO% content is 19%.

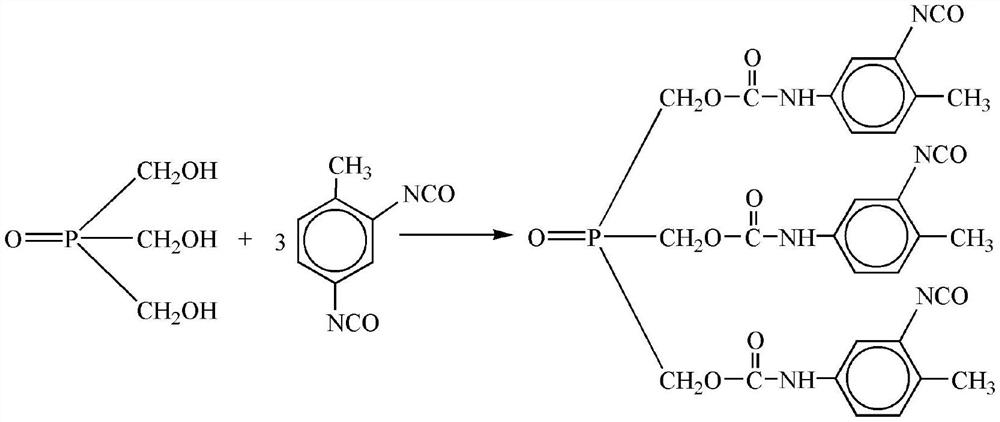

[0037] A highly flame-retardant polyurethane foam material for vehicle seats based on modified isocyanate in this embodiment is formed by polymerizing modified isocyanate and polyol components, wherein the modified isocyanate uses trimethylolphosphine oxide Polymerized with TDI, the reaction equation is as follows:

[0038]

[0039] The reference synthesis process of modified isocyanate is:

[0040] (1) Heat the reactor to 48°C-52°C;

[0041] (2) According to the molar ratio of trimethylolphosphine oxide (purchase...

Embodiment 3

[0071] The index of embodiment 3 and embodiment 4 keep the amount of cyanate ester constant under the situation of 114 parts, without adding physical flame retardant, the oxygen index increases from 19.5% of non-flame retardant to 26.3% of flame retardant, while TVOC They are 34μgC / g and 31μgC / g respectively, and the odor level (80°C) is 3.5 and 3.5 respectively, which shows little change, indicating that the modified isocyanate of the present invention can simultaneously improve the flame retardancy of polyurethane foam while avoiding the purpose of flame retardants from reducing environmental protection indicators . It solves the problem of conflicting environmental protection indicators such as high flame retardancy, low TVOC and low odor.

[0072] Test example 3 index and test example 5 keep the amount of cyanate ester constant under the situation of 114 parts, test examples 3 and 5 improve foam flame retardancy by using modified isocyanate compound, adding physical flame ...

Embodiment 6

[0073] Example 6 The proportion of modified isocyanate and the weight ratio of polyols is 1.5:1, the phosphorus content in the foam system has increased to 2.82%, the oxygen index has increased to more than 28%, and environmental indicators such as TVOC, odor level (80 ° C), formaldehyde The release amount and the fog test remained basically unchanged, indicating that the modified isocyanate compound of the present invention can achieve the purpose of simultaneously improving the flame retardancy of polyurethane foam and avoiding the reduction of environmental protection indicators by flame retardants. It solves the problem of conflicting environmental protection indicators such as high flame retardancy, low TVOC and low odor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com