Flame retardant modified asphalt colored asphalt tile

A technology of modified asphalt and asphalt tiles, which is applied in the field of waterproof and flame-retardant composite materials for building roofs. The effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

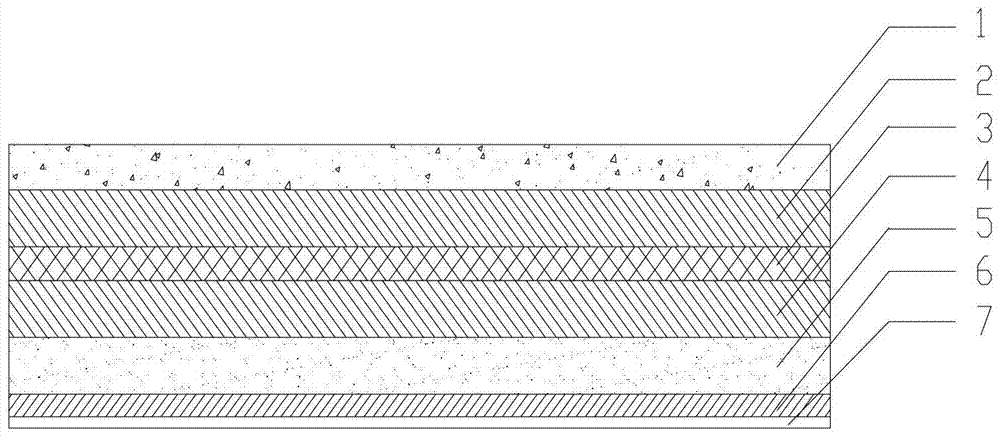

[0023] Preparation of Flame Retardant Modified Asphalt Colored Asphalt Tile

[0024] 1. Preparation of flame retardant modified asphalt mixture for flame retardant modified asphalt layer

[0025] According to the parts by weight, first add 40~45 parts of heavy traffic asphalt into the reactor, heat up to 150°C for dehydration under stirring, and add 8~15 parts of naphthenic oil and styrene according to parts by weight when the temperature is raised to 200±5°C -4~8 parts of butadiene-styrene, and stirred at 200±5°C for 90 minutes to dissolve styrene-butadiene-styrene evenly, then add 30~35 parts of talcum powder, and stir for 60 minutes, Finally, lower the temperature to 130°C~150°C, add 4~8 parts of composite flame retardant, and stir for 30 minutes to make a flame-retardant modified asphalt mixture; set aside.

[0026] The heavy-duty asphalt in the flame-retardant modified asphalt layer of the present invention is No. 90 heavy-duty asphalt, and the composite flame retardant ...

Embodiment 1

[0030] Embodiment 1 (every part by weight is 100 kilograms, all the other embodiments are the same)

[0031] Add 4,000 kilograms of No. 90 heavy-duty asphalt into the reactor, heat up to 150°C for dehydration under stirring, and add 800 kilograms of naphthenic oil and 600 kilograms of styrene-butadiene-styrene in parts by weight at 195°C. And stir at 195°C for 90 minutes to dissolve styrene-butadiene-styrene evenly, then add 3000 kg of talcum powder, stir for 60 minutes, finally cool down to 130°C, add 400 kg of composite flame retardant, and stir for 30 minutes Minutes to prepare flame retardant modified asphalt mixture for use.

Embodiment 2

[0033] Add 4,200 kilograms of No. 90 heavy-duty asphalt in the reaction kettle, heat up and dehydrate under the stirring state, add 1,100 kilograms of naphthenic oil and 650 kilograms of styrene-butadiene-styrene according to parts by weight at 200 ° C, and Stir at ℃ for 90 minutes to dissolve styrene-butadiene-styrene evenly, then add 3200 kg of talc powder, stir for 60 minutes, finally cool down to 140°C, add 550 kg of composite flame retardant, and stir for 30 minutes to prepare into a flame retardant modified asphalt mixture for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com