Anti-aging flame-retardant pipeline material and preparation method thereof

An anti-aging and pipeline technology, applied in the field of plastic drainage pipes, can solve the problems of poor anti-aging weather resistance, poor heat resistance and poor toughness of pipelines, and achieves increased anti-aging ability, low production equipment requirements, and improved flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

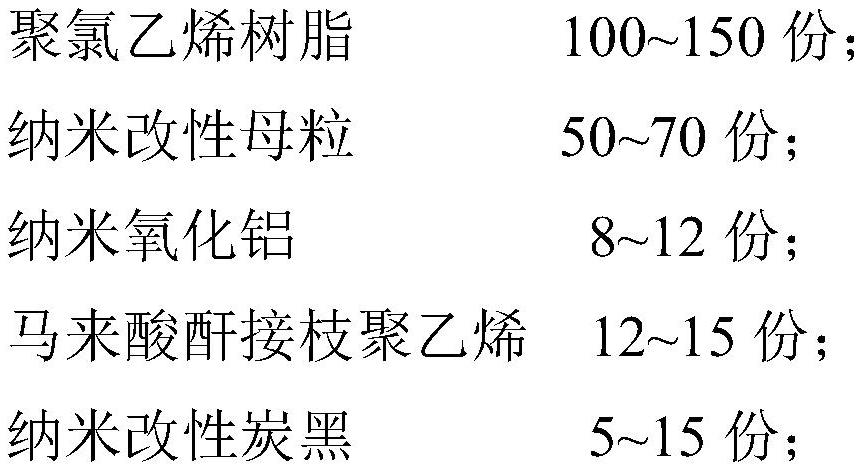

[0033] An anti-aging flame-retardant pipeline material, comprising the following ingredients in parts by weight:

[0034]

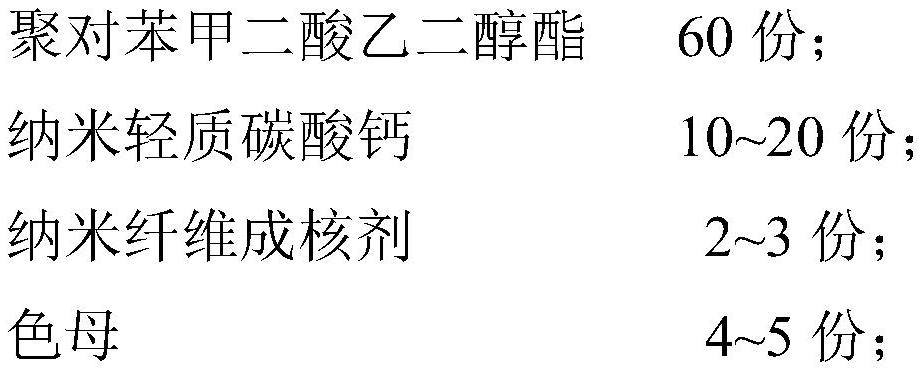

[0035] Among them, the nano-modified masterbatch is mixed with polyethylene terephthalate, nano-light calcium carbonate, nano-fiber nucleating agent and color masterbatch at high speed; polyethylene terephthalate, nano-light Calcium carbonate, nanofiber nucleating agent and masterbatch comprise the following components by weight:

[0036]

[0037] Wherein, the modified nano-carbon black is prepared by treating the oxidized carbon black with a modifier. Modifier is prepared by the following steps:

[0038] Step 1: Mix o-amino-p-cresol, deionized water, and concentrated hydrochloric acid at 0.01mol:15mL:2mL at a speed of 150-200r / min and a temperature of 5°C, add 0.69g of sodium nitrite, and react Until the reaction solution is alkaline, the azo precursor solution is prepared. Mix m-phenylenediamine, deionized water, and concentrated hydrochloric ac...

Embodiment 2

[0053] An anti-aging flame-retardant pipeline material, comprising the following ingredients in parts by weight:

[0054]

[0055] Among them, the nano-modified masterbatch is mixed with polyethylene terephthalate, nano-light calcium carbonate, nano-fiber nucleating agent and color masterbatch at high speed; polyethylene terephthalate, nano-light Calcium carbonate, nanofiber nucleating agent and masterbatch comprise the following components by weight:

[0056]

[0057] Wherein, the modified nano-carbon black is prepared by treating the oxidized carbon black with a modifier. Modifier is prepared by the following steps:

[0058] Step 1: Mix o-amino-p-cresol, deionized water, and concentrated hydrochloric acid at 0.01mol:15mL:2mL at a speed of 150-200r / min and a temperature of 5°C, add 0.69g of sodium nitrite, and react Until the reaction solution is alkaline, the azo precursor solution is prepared. Mix m-phenylenediamine, deionized water, and concentrated hydrochloric ac...

Embodiment 3

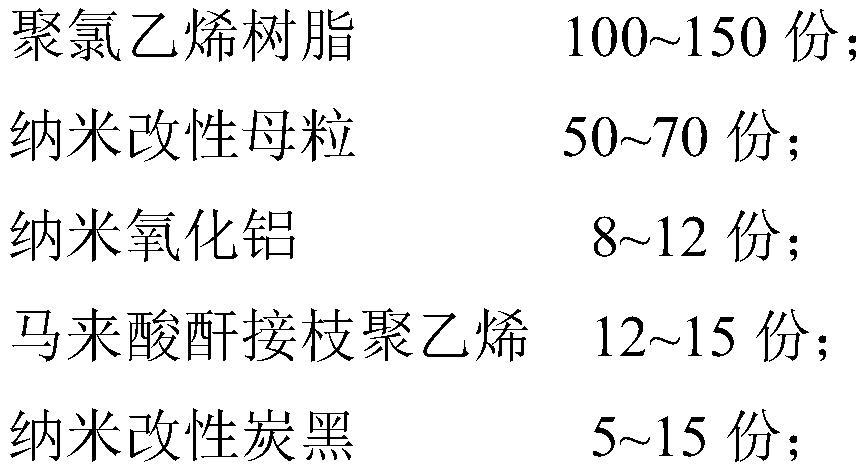

[0070] An anti-aging flame-retardant pipeline material, comprising the following ingredients in parts by weight:

[0071]

[0072] Among them, the nano-modified masterbatch is mixed with polyethylene terephthalate, nano-light calcium carbonate, nano-fiber nucleating agent and color masterbatch at high speed; polyethylene terephthalate, nano-light Calcium carbonate, nanofiber nucleating agent and masterbatch comprise the following components by weight:

[0073]

[0074] Wherein, the modified nano-carbon black is prepared by treating the oxidized carbon black with a modifier. Modifier is prepared by the following steps:

[0075] Step 1: Mix o-amino-p-cresol, deionized water, and concentrated hydrochloric acid at 0.01mol: 15mL: 2mL at a speed of 150-200r / min and a temperature of 5°C, add 0.69g of sodium nitrite, and react Until the reaction solution is alkaline, the azo precursor solution is prepared. Mix m-phenylenediamine, deionized water, and concentrated hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com