Manufacturing method of polyacrylamide gel substrate with single cell pattern array

A technology of polyacrylamide gel and polyacrylamide, applied in fluorescence/phosphorescence, instruments, analytical materials, etc., can solve the problems of long production time, complicated operation process, low flux, etc. The effect of high consistency and large application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1 of the present disclosure takes the preparation of a polyacrylamide gel substrate with a single-cell pattern array as an example, and further elaborates the implementation process of the method for making a polyacrylamide gel substrate with a single-cell pattern array provided by the present disclosure .

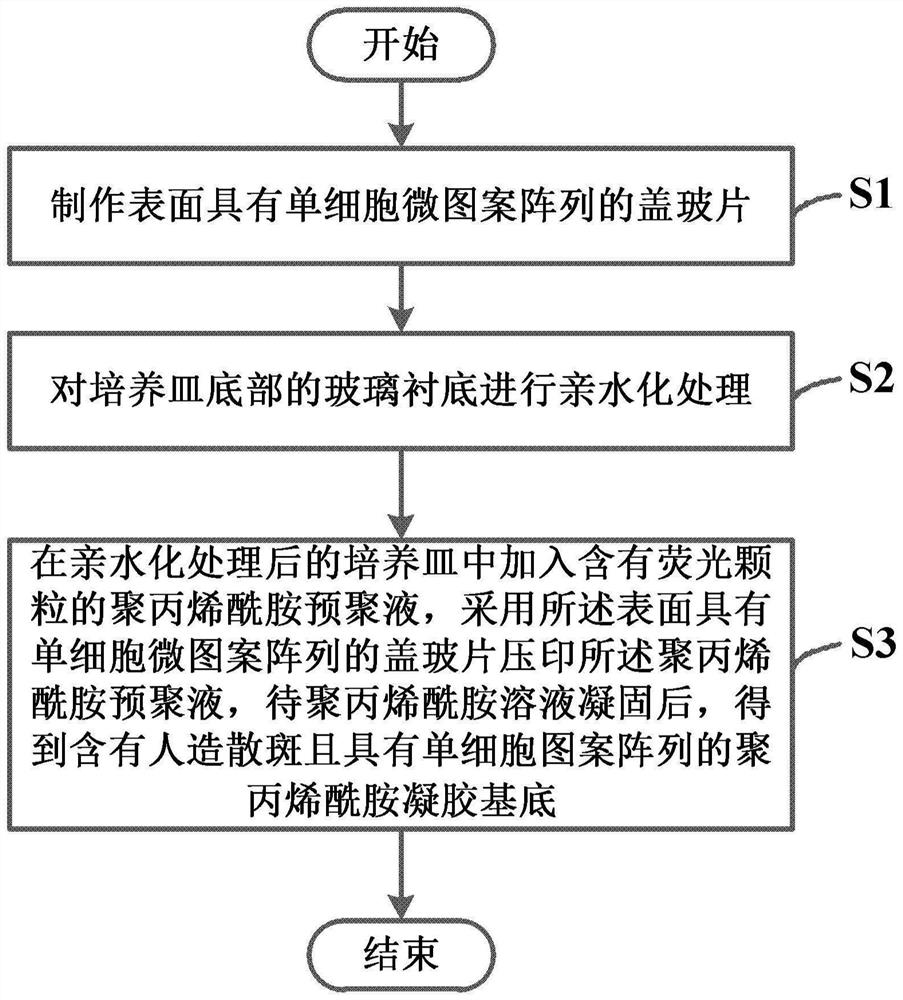

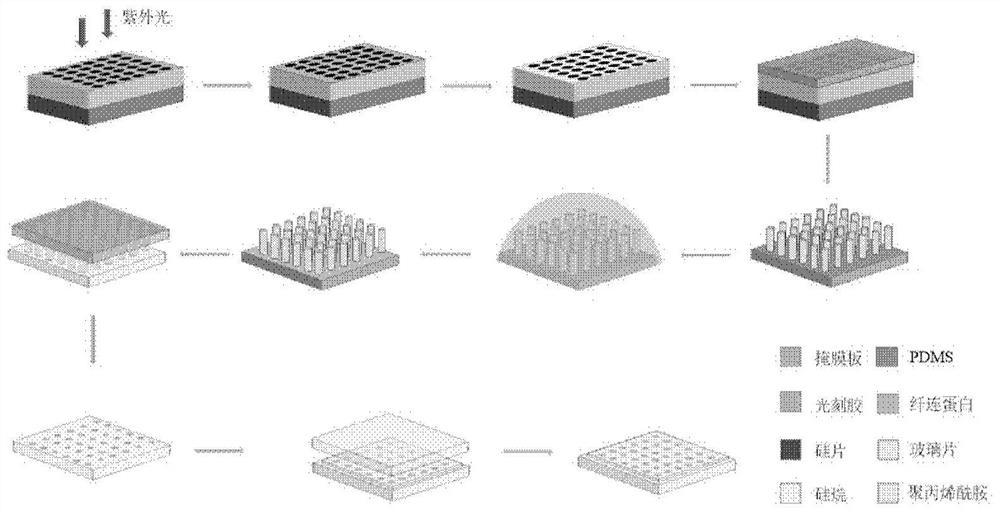

[0075] Such as figure 2 as shown, figure 2 It is a process flow chart of making a polyacrylamide gel substrate with a single-cell pattern array according to an embodiment of the present disclosure, which specifically includes the following steps:

[0076] Step 1: Activation of the glass plate;

[0077] 1.1 Preparation of hydrophilic glass substrate, specifically including:

[0078] Clean the confocal culture dish with ultrasound and rinse it;

[0079] Soak the confocal culture dish with 0.1% sodium hydroxide solution or methanol for 5 minutes, and then dry it at room temperature;

[0080] Then, a layer of 3-(methacryloyloxy)propyltrimethoxysilane acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com