Monitoring device and monitoring method for growth of bacteria/cells

A monitoring device and bacteria technology, applied in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of lack of physiological environment bacteria/cell growth monitoring, response ability, etc., and achieve improved conductivity and biocompatibility improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Pretreatment: Pickling the titanium sheet, during pickling, the pickling solution is composed of HF with a mass fraction of 40%, and HNO with a mass fraction of 60%. 3 Mixed, pickling time is 10min; HF, HNO 3 The volume ratio of Ti is 1:5; after pickling, it is washed and dried, and ultrasonically cleaned with deionized water for 10 min, and dried at room temperature for later use, abbreviated as Ti.

[0055] (2) Surface treatment: polish the titanium sheet pretreated in step (1) with 400, 800, and 1200 mesh sandpaper in sequence until the surface is smooth and free of scratches;

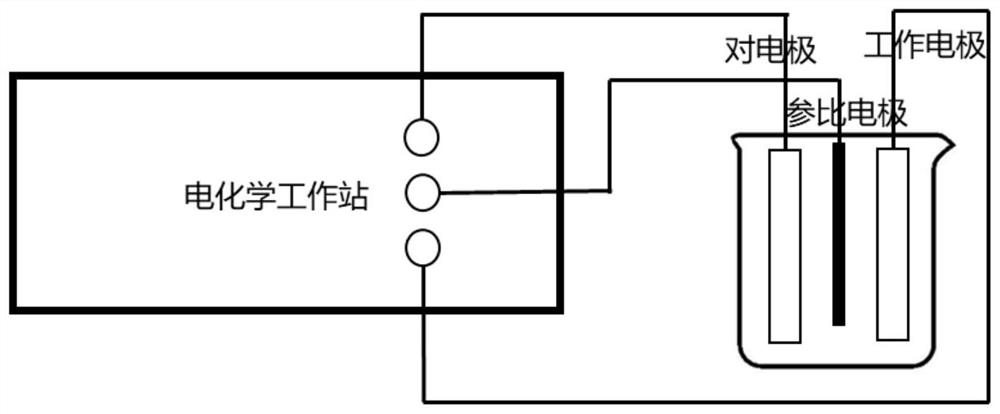

[0056] (3) Electrodeposition: the titanium or titanium alloy processed in step (2) is used as a working electrode, the graphite sheet is used as a counter electrode, and a saturated calomel electrode is used as a reference electrode, and electrodeposition is carried out in a solution containing dopant and Py ( Such as figure 1 shown), the obtained samples were cleaned with deionized wa...

Embodiment 2

[0058] (1) Pretreatment: Pickling the titanium sheet, during pickling, the pickling solution is composed of HF with a mass fraction of 40%, and HNO with a mass fraction of 60%. 3 Mixed, pickling time 5min; HF, HNO 3 The volume ratio is 1:4. Wash and dry, and ultrasonically clean with deionized water for 10 min, and dry at room temperature before use, abbreviated as Ti.

[0059] (2) Surface treatment: polish the titanium sheet pretreated in step (1) with 600 mesh, 1200 mesh, and 2000 mesh sandpaper in sequence until the surface is smooth without scratches for later use;

[0060] (3) Electrodeposition: the titanium or titanium alloy processed in step (2) is used as a working electrode, the graphite sheet is used as a counter electrode, and a saturated calomel electrode is used as a reference electrode, and electrodeposition is carried out in a solution containing dopant and Py, The obtained samples were cleaned successively with deionized water and ethanol, and dried in an ove...

Embodiment 3

[0062] (1) Pretreatment: carry out pickling to sample, during pickling, the pickling solution is 40% HF by mass fraction, the HNO that mass fraction is 60% 3 Mixed, pickling time is 5min; HF, HNO 3 The volume ratio is 1:6. Wash and dry, and ultrasonically clean with deionized water for 10 min, and dry at room temperature before use, abbreviated as Ti.

[0063] (2) Surface treatment: polish the titanium sheet pretreated in step (1) with 400 mesh, 1000 mesh, and 2000 mesh sandpaper in sequence until the surface is smooth without scratches for later use;

[0064] (3) Electrodeposition: the titanium or titanium alloy processed in step (2) is used as a working electrode, the graphite sheet is used as a counter electrode, and a saturated calomel electrode is used as a reference electrode, and electrodeposition is carried out in a solution containing dopant and Py, The obtained samples were cleaned successively with deionized water and ethanol, and dried in an oven; wherein, the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com