Method for detecting thickness of surface corrosion layer of electronic component

A technology of electronic components and detection methods, applied in the field of analysis and detection, can solve the problems of difficult sample preparation, high detection limit of elements, inability to accurately obtain the thickness of corrosion layer, etc., and achieve simple and convenient detection steps, high detection sensitivity and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

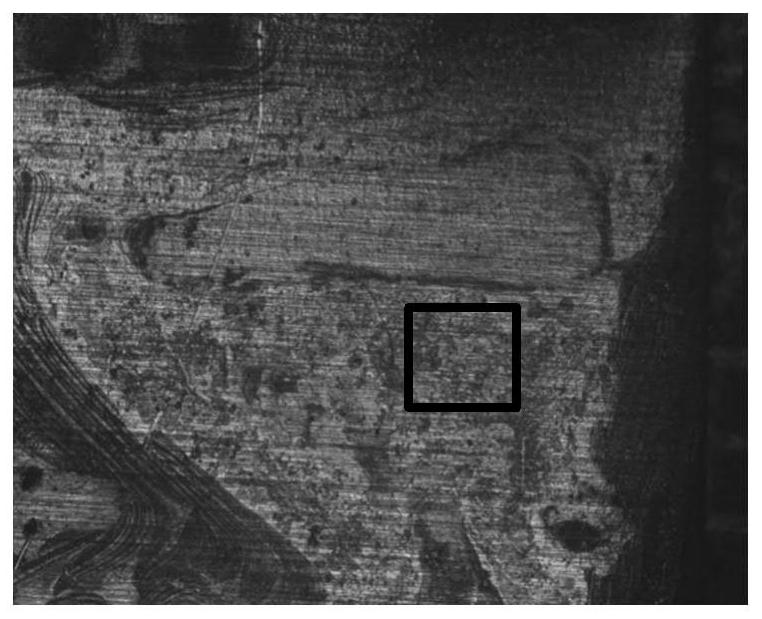

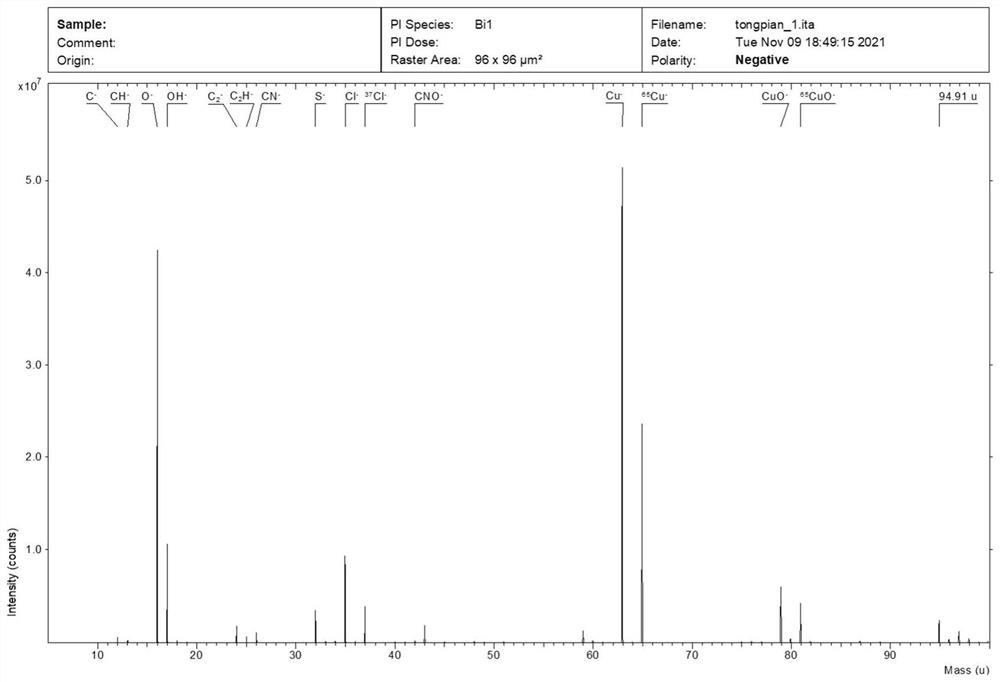

[0071] This embodiment provides a kind of detection method of the thickness of corrosion layer on the surface of electronic components and parts, the sample of detection is: the copper sheet that the purity inside electronic device is 99.9%, corrosion occurs on the surface of this copper sheet (such as figure 1 and figure 2 Shown), the thickness of the corrosion layer is required to be tested.

[0072] The specific detection method is as follows:

[0073] S1: Fix the above-mentioned copper sheet (the surface height difference does not exceed 0.5 μm) on the surface of the sample stage, put it into the auxiliary chamber of the IonTOF time-of-flight secondary ion mass spectrometer, and vacuum until the vacuum degree reaches 4.7×10 -7 After mbar, send the sample into the main chamber;

[0074] S2: Wait until the vacuum degree of the main chamber reaches 9.0×10 -9 After mbar, turn on the LMIG power supply, Analyzer power supply and 2ndGun power supply, load the LMIG source, cal...

Embodiment 2

[0082] The present embodiment provides a kind of detection method of the thickness of corrosion layer on the surface of electronic components and parts, and the sample of detection is: the ceramic capacitor (see Figure 6 ), it is required to test the thickness of the corrosion layer of the terminal electrode.

[0083] The specific detection method is as follows:

[0084]S1: Fix the above-mentioned ceramic capacitor (the surface height difference does not exceed 0.5 μm) on the surface of the sample stage, put it into the auxiliary chamber of the Ion TOF time-of-flight secondary ion mass spectrometer, and vacuum until the vacuum degree reaches 6.4× 10 -7 After mbar, send the sample into the main chamber;

[0085] S2: Wait until the vacuum degree of the main chamber reaches 1.2×10 -8 After mbar, turn on the LMIG power supply, Analyzer power supply and 2ndGun power supply, load the LMIG source, calibrate the beam current of the LMIG source, and adjust the beam current size: 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com