First wall structure for fusion reactor high-dose neutron irradiation and megawatt-level thermal load

A high-dose, fusion reactor technology, applied in the field of fusion reactors, can solve the problems of the helium-cooled first wall being unable to meet the needs of CFETR fusion reactors, limiting the heat-carrying capacity and service life of the first wall, and failing to meet the high heat load of fusion reactors, etc. Achieve the effect of improving thermoelectric conversion efficiency, improving the comprehensiveness of anti-irradiation and high thermal load resistance, and improving high thermal load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

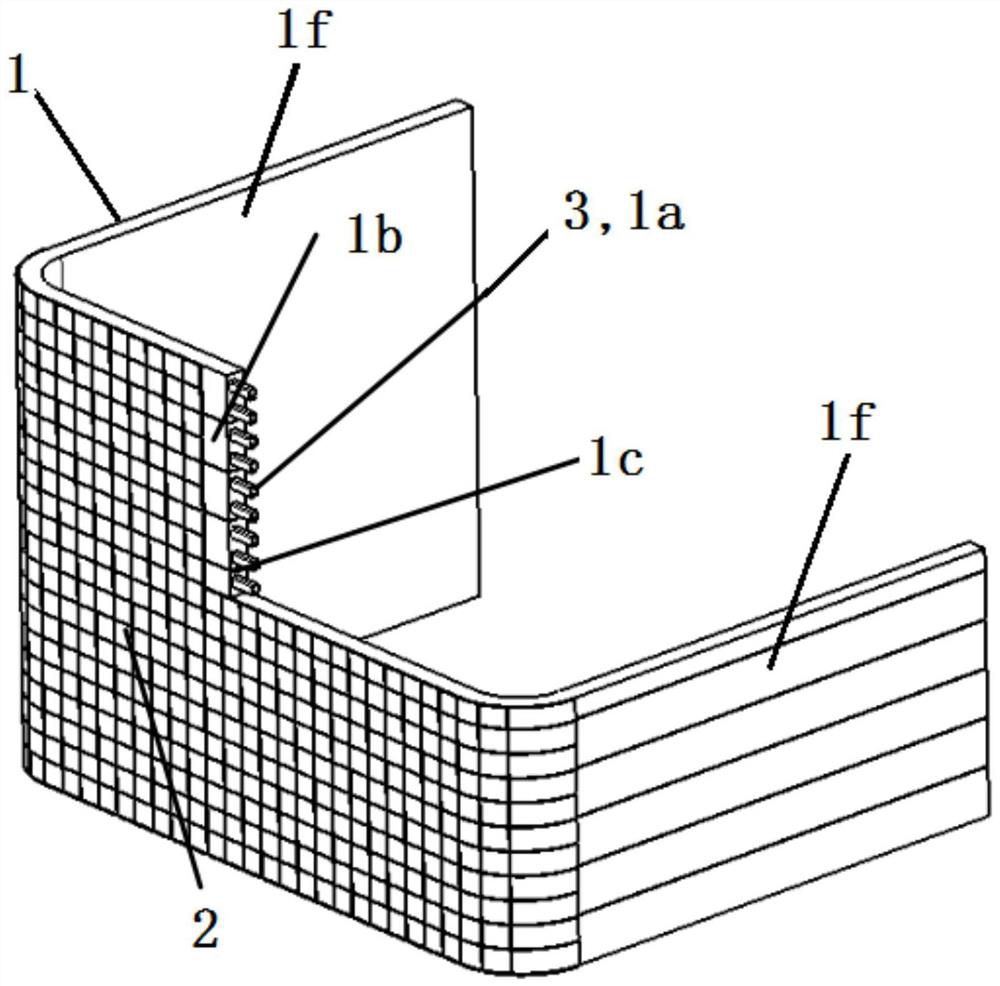

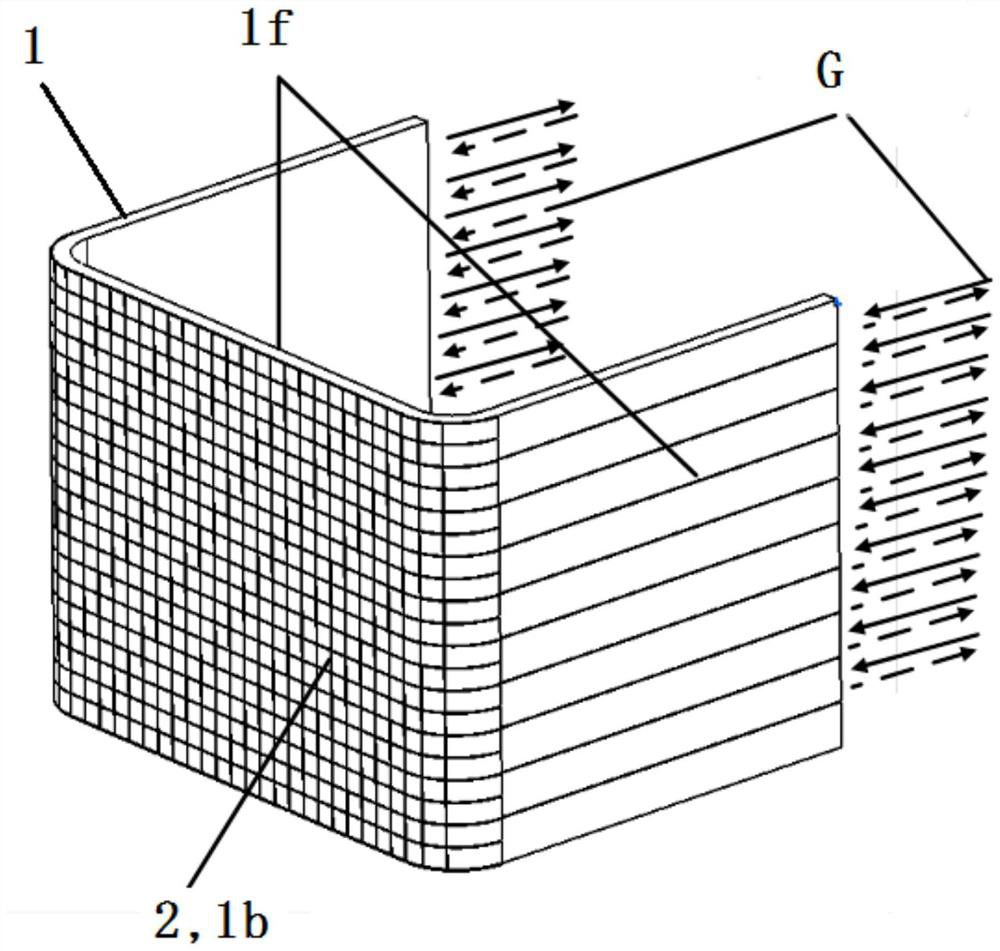

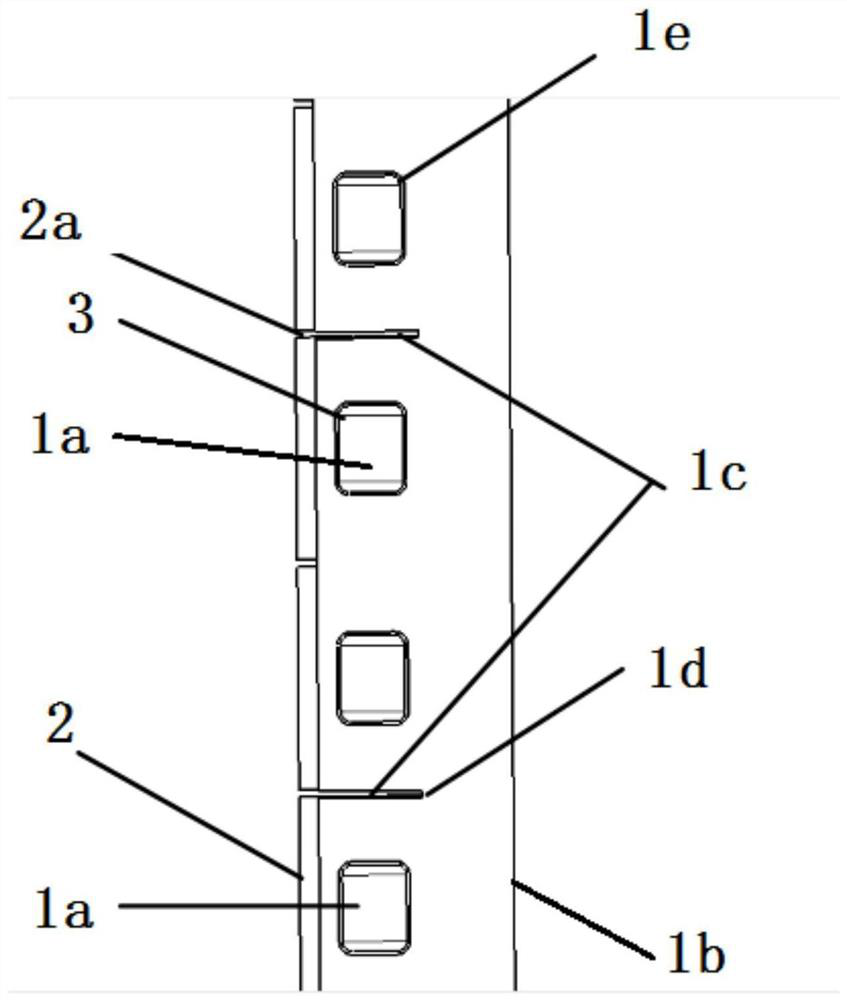

[0029] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a first wall structure for fusion reactor neutron irradiation and megawatt heat load, the first wall structure includes a first wall body 1, a protective layer 2 and a flow channel lining 3. The first wall body 1 is in the shape of a "U" as a whole. There are 10 flow channels 1a arranged parallel to each other in the first wall body 1. The front wall 1b of the first wall body 1 has 9 flow channels 1a arranged in parallel in the lateral direction. Gap 1c between runners, each gap 1c between runners is located between the upper and lower runners; each gap 1c between runners is provided with gap chamfering 1d between runners, each runner 1a is equipped with a runner Chamfer 1e. Each flow channel 1a is welded with a flow channel liner 3 . The outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com