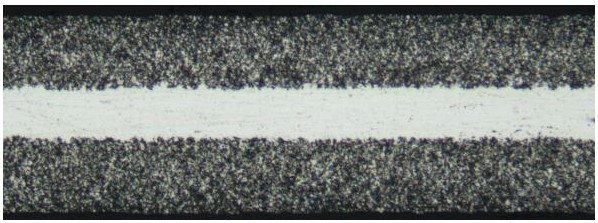

Manufacturing method of light edge controllable electrode foil for solid aluminum electrolytic capacitor

A technology for an aluminum electrolytic capacitor and a manufacturing method, applied in the field of electrode foil manufacturing, can solve problems such as difficulty in corroding the same position of the foil, waste of aluminum foil resources, and left and right offset of the corroded foil, achieving excellent electrochemical corrosion resistance and eliminating a lot of waste , the effect of clear direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for manufacturing an electrode foil with controllable smooth edges for a solid aluminum electrolytic capacitor comprises the following steps:

[0043] S1. Degreasing the surface of the aluminum foil, specifically: immerse the aluminum foil in an organic solution (any one or a mixture of organic solutions from banana water, turpentine, alcohol, gasoline and kerosene).

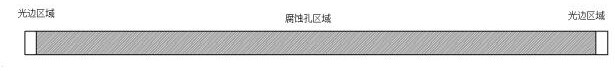

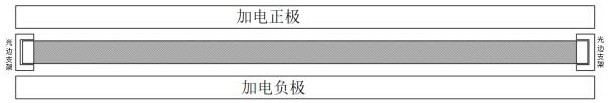

[0044] S2. Perform a local coating operation on the aluminum foil obtained in step S1 to simultaneously form a corrosion-resistant coating layer A, a corrosion-resistant coating layer B, a corrosion-resistant coating layer C, and a corrosion-resistant coating layer D; the aluminum foil obtained in step S1 The front side is divided into a pre-coating area A and a pre-coating area B, which are covered by the corrosion-resistant coating layer A and the corrosion-resistant pre-coating area B in a one-to-one correspondence; the pre-coating area A and the pre-coating area B are respectively provided by ...

Embodiment 2

[0060] A method for manufacturing an electrode foil with controllable smooth edges for a solid aluminum electrolytic capacitor comprises the following steps:

[0061] S1. Degreasing the surface of the aluminum foil, specifically: immerse the aluminum foil in an organic solution (any one or a mixture of organic solutions from banana water, turpentine, alcohol, gasoline and kerosene).

[0062] S2. Perform a local coating operation on the aluminum foil obtained in step S1 to simultaneously form a corrosion-resistant coating layer A, a corrosion-resistant coating layer B, a corrosion-resistant coating layer C, and a corrosion-resistant coating layer D; the aluminum foil obtained in step S1 The front side is divided into a pre-coating area A and a pre-coating area B, which are covered by the corrosion-resistant coating layer A and the corrosion-resistant pre-coating area B in a one-to-one correspondence; the pre-coating area A and the pre-coating area B are respectively provided by ...

Embodiment 3

[0078] A method for manufacturing an electrode foil with controllable smooth edges for a solid aluminum electrolytic capacitor comprises the following steps:

[0079] S1. Degreasing the surface of the aluminum foil, specifically: immerse the aluminum foil in an organic solution (any one or a mixture of organic solutions from banana water, turpentine, alcohol, gasoline and kerosene).

[0080] S2. Perform a local coating operation on the aluminum foil obtained in step S1 to simultaneously form a corrosion-resistant coating layer A, a corrosion-resistant coating layer B, a corrosion-resistant coating layer C, and a corrosion-resistant coating layer D; the aluminum foil obtained in step S1 The front side is divided into a pre-coating area A and a pre-coating area B, which are covered by the corrosion-resistant coating layer A and the corrosion-resistant pre-coating area B in a one-to-one correspondence; the pre-coating area A and the pre-coating area B are respectively provided by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com