Koji powder crushing preparation equipment

A koji powder and equipment technology, which is applied in the field of koji powder crushing and preparation equipment, can solve problems such as crusher corrosion, production accidents, and crusher efficiency decline, and achieve the effect of reducing waste and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

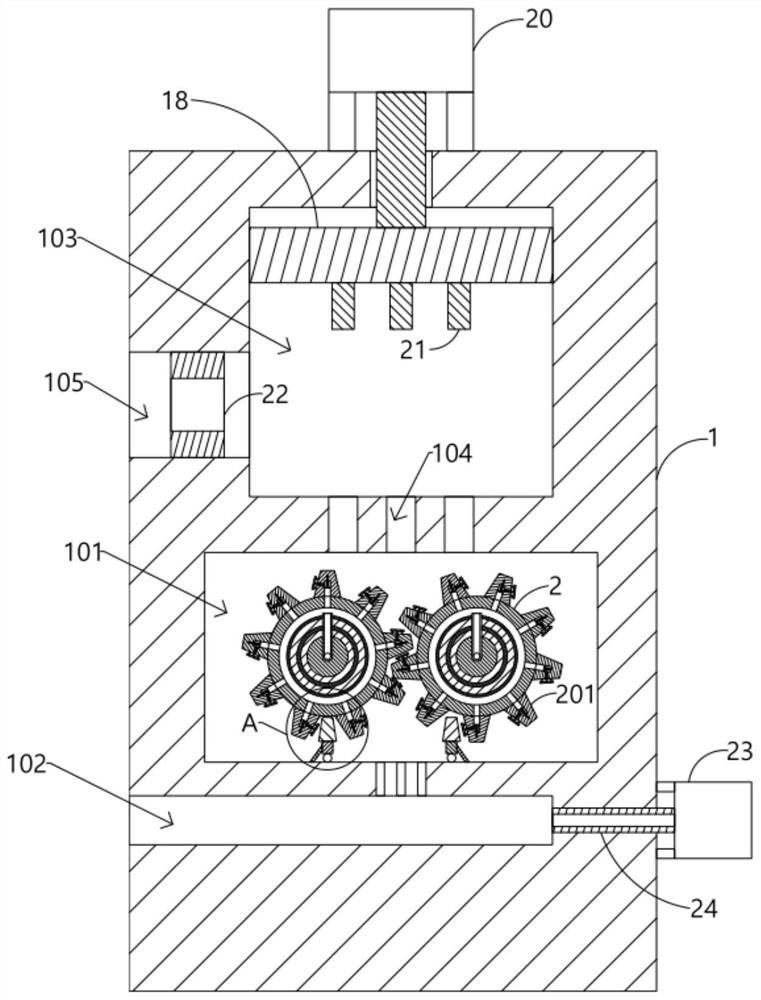

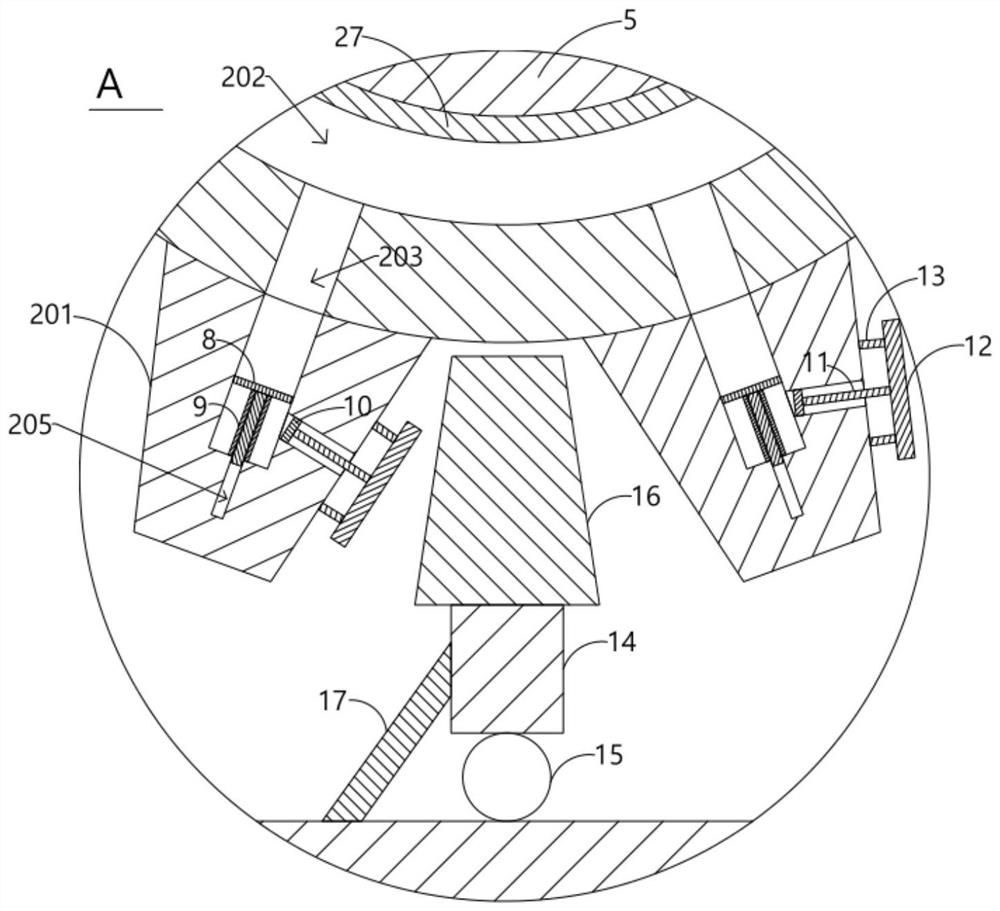

[0033] A kind of koji powder crushing and preparation equipment, including a crushing box 1 with a crushing cavity 101 inside, and the bottom of the crushing cavity 101 communicates with the powder outlet channel 102 through a plurality of second filter tanks, so that only the powder whose size is smaller than the inner diameter of the second filter tank Only then can it enter the powder outlet channel 102 through the crushing chamber 101 to ensure the quality of the collected koji powder powder. The opening of the powder outlet channel 102 is preferably set downwards, so that the crushed koji powder powder leaves the powder outlet channel 102. The crushing chamber 101 There are two rotating columns 2 which are rotated at intervals in the left and right. The two rotating columns 2 can be driven by an external motor to rotate, or a hand-held rotating rod extending out of the crushing box 1 can be extended from the end of the rotating column 2, and can be manually held and rotated...

Embodiment 2

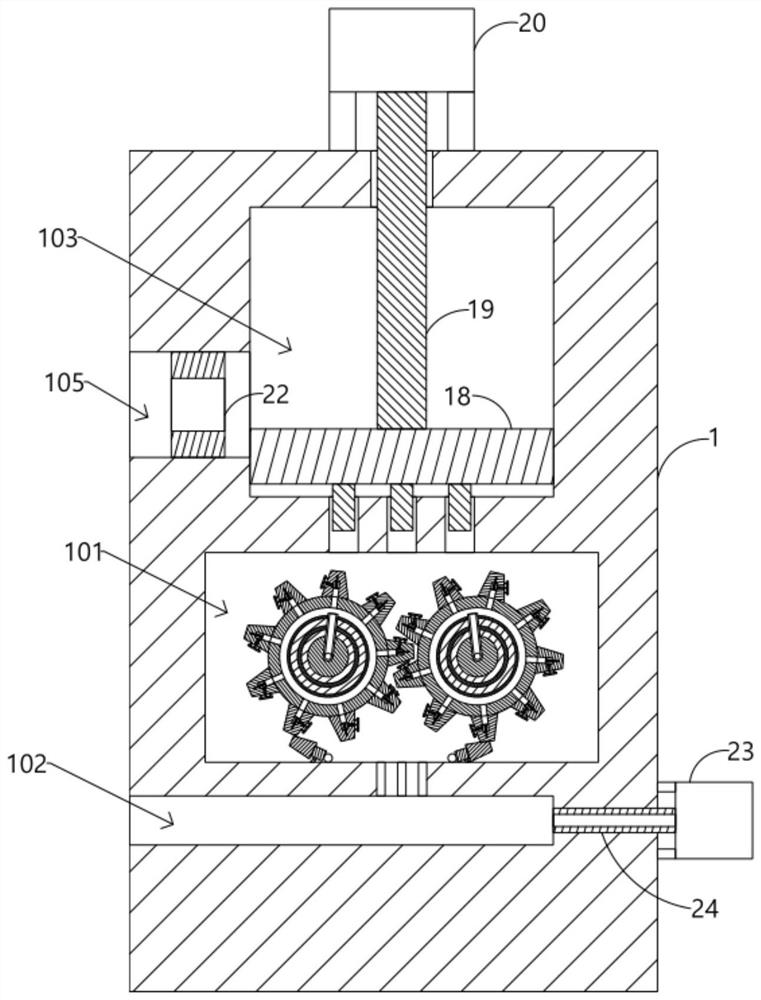

[0040] Embodiment 2 adds a pre-crushing process on the basis of Embodiment 1, that is: the upper part of the crushing chamber 101 is connected with a pre-crushing chamber 103 through the first filter tank 104, and the pre-crushing chamber 103 is connected with a feed tank 105, and the feed tank 105 is provided with a feed valve 22, and the bent pieces enter the pre-crushing chamber 103 through the feed trough 105, and a crushing platen 18 is slidably arranged in the pre-crushing chamber 103, and a driving rod 19 is fixedly connected to the top of the crushing platen 18, and the driving rod 19 The end far away from the crushing platen 18 is installed on the output end of the electric drive cylinder 20. The electric drive cylinder 20 drives the crushing platen 18 to slide up and down through the drive rod 19, and the crushing platen 18 slides downward and squeezes the curved block to break, so that the curved block is broken into pieces. The small pieces enter the crushing cavity...

Embodiment 3

[0042] Embodiment 3 Improve the automation level of the equipment on the basis of Embodiment 1, that is: the end of the powder outlet channel 102 away from its opening is connected with the blast pipe 24, and the end of the blast pipe 24 away from the powder outlet channel 102 is installed on the On the air outlet end of the blower 23, the blower 23 blasts air into the powder outlet channel 102 through the air blast duct 24, so that the koji powder in the powder outlet channel 102 can leave the powder outlet channel 102 more easily, and the ends of the rotating column 2 are fixedly connected There is a rotating rod 25, and the end of the rotating rod 25 away from the rotating column 2 is installed on the output end of the bidirectional driving motor 26. The setting of the bidirectional driving motor 26 improves the automation level of the device and reduces the labor intensity of the workers. When the block is bent, the rotating column 2 is driven forward to rotate, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com