Reverse wetting agent as well as preparation method and application thereof

A technology of wetting reversal and reaction products, applied in the field of petroleum exploration, can solve the problems of reduced drag reduction rate of slick water, difficult cracks, and large filtration loss, etc., to increase the effective flow radius of pore throats and weaken the physical and chemical effects. , the effect of reducing the saturation of bound water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0061] The object of this preparation example is to prepare a wetting reversing agent A1 containing 10% alkyltrimethylammonium bromide, 0.3% perfluorolauryl polyoxyethylene ether, 5% fatty acids and 84.7% water.

[0062] Step 1: Under the condition of continuous stirring at 800rpm, add water, alkyltrimethylammonium bromide and perfluorolauryl polyoxyethylene ether in order.

[0063] Step 2: Under the condition of continuous stirring at 800 rpm, add fatty acids to the solution obtained in step 1 until it is completely dissolved to obtain the reaction system.

[0064] Step 3: Under the condition of continuous stirring at 800 rpm and the reaction system prepared by stirring step 2 at a temperature of 35 °C for 1 hour, the wetting reversing agent A1 was obtained.

Embodiment 1

[0066] The present embodiment is used to illustrate the preparation and performance characterization of a water slip system.

[0067] (1) Take 99.3g of water, pour it into the agitator, adjust the speed of the agitator until the whirlpool formed by the liquid can see the top of the shaft of the mixer pulp leaf.

[0068] (2) Slowly and evenly add the weighed anti-drag agent 0.1g, stirring for 5min ~ 10min to make it completely dissolved.

[0069] (3) Add 0.3g of the weighed clay stabilizer and stir continuously to make it mix evenly.

[0070] (4) Add the wetting reversing agent A10.3g prepared by the weighed preparation example 1, continuously stir for 2min, form a uniform solution, stop stirring, and get a slippery water system for backup.

[0071] The performance of the prepared water slip system was tested, and the results showed that the surface tension was 19.1 mN / m and the interfacial tension was 0.9 mN / m, and the contact angle of the water slip system was 123°, and the conta...

Embodiment 2-3

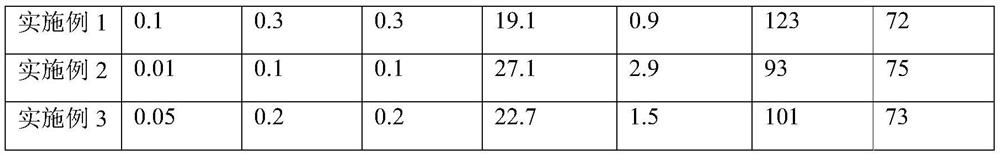

[0073] The steps of Examples 2-3 are substantially consistent with Example 1, the difference is that the dosage of each component is changed (the specific dosage of each component is shown in Table 1 below, water is the margin) to prepare a slippery water system and test its performance, the result is shown in Table 1.

[0074] Table 1

[0075]

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| resistance reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com