Method for growing silicon oxide thick film by adopting TEOS source PECVD

A technology of silicon oxide and thick film, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problems of growth rate limitation, difficulty in obtaining silicon oxide film, thick film brittleness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

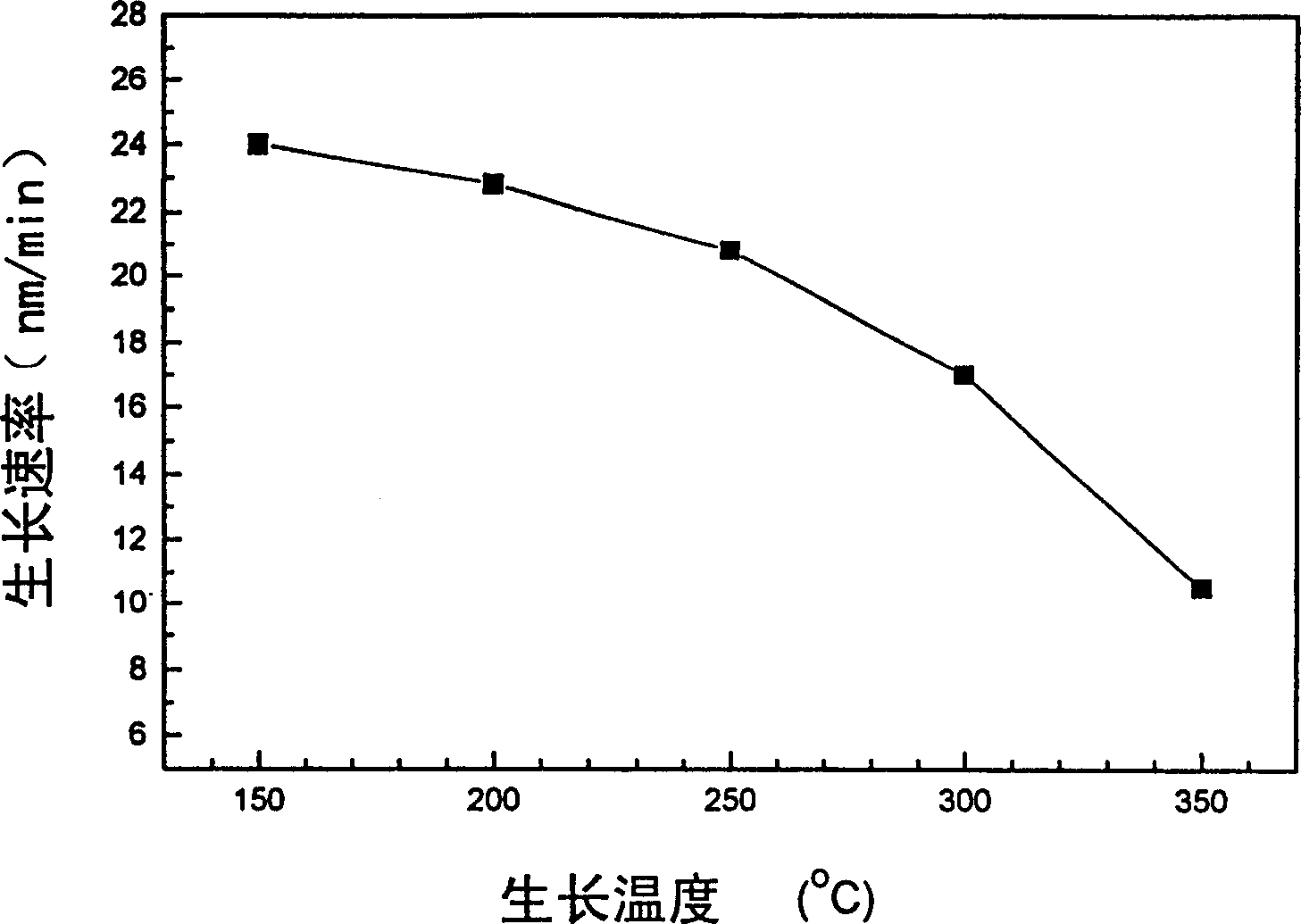

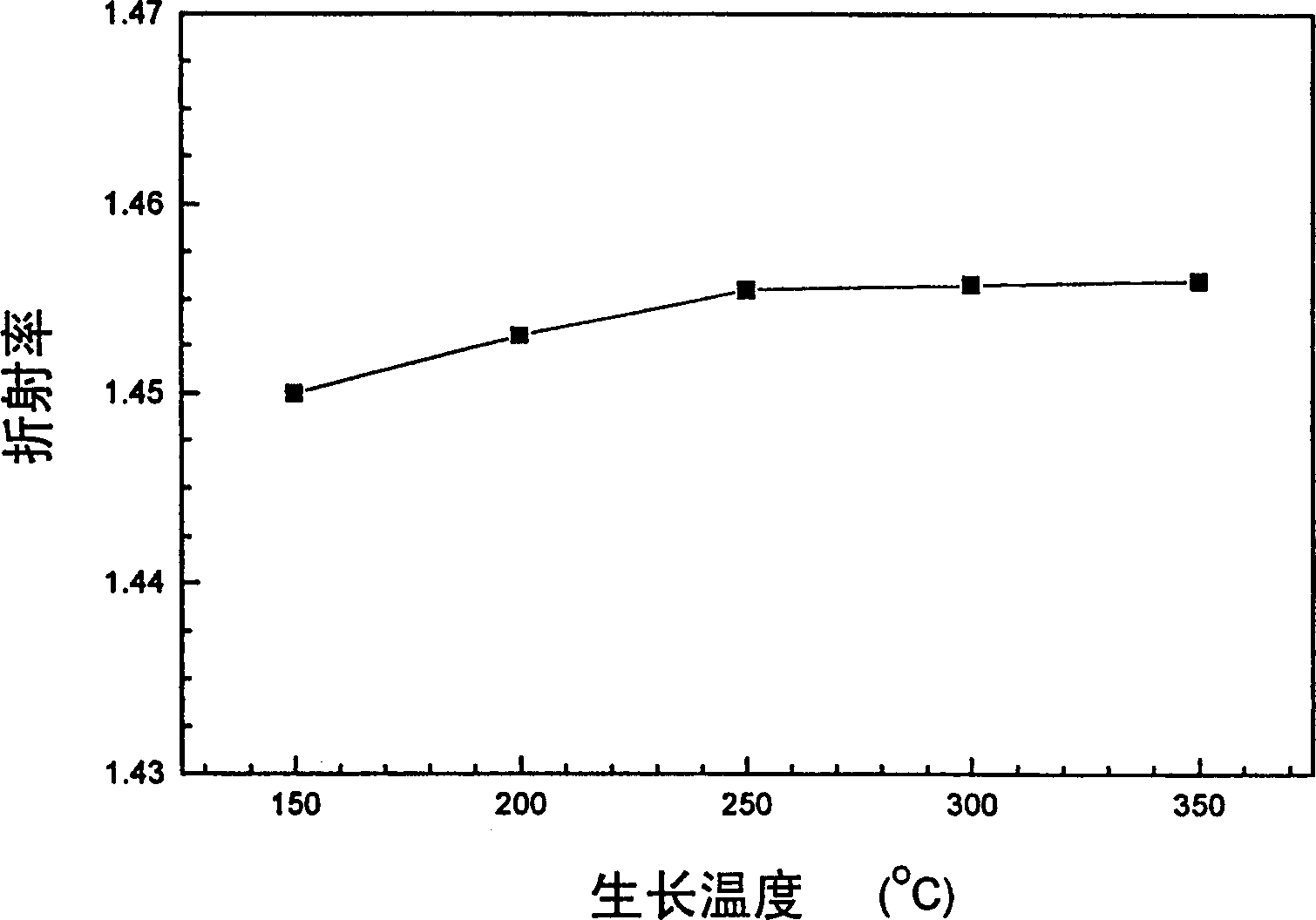

[0014] Table 1 Reaction conditions for silicon oxide growth by TEOS-PECVD

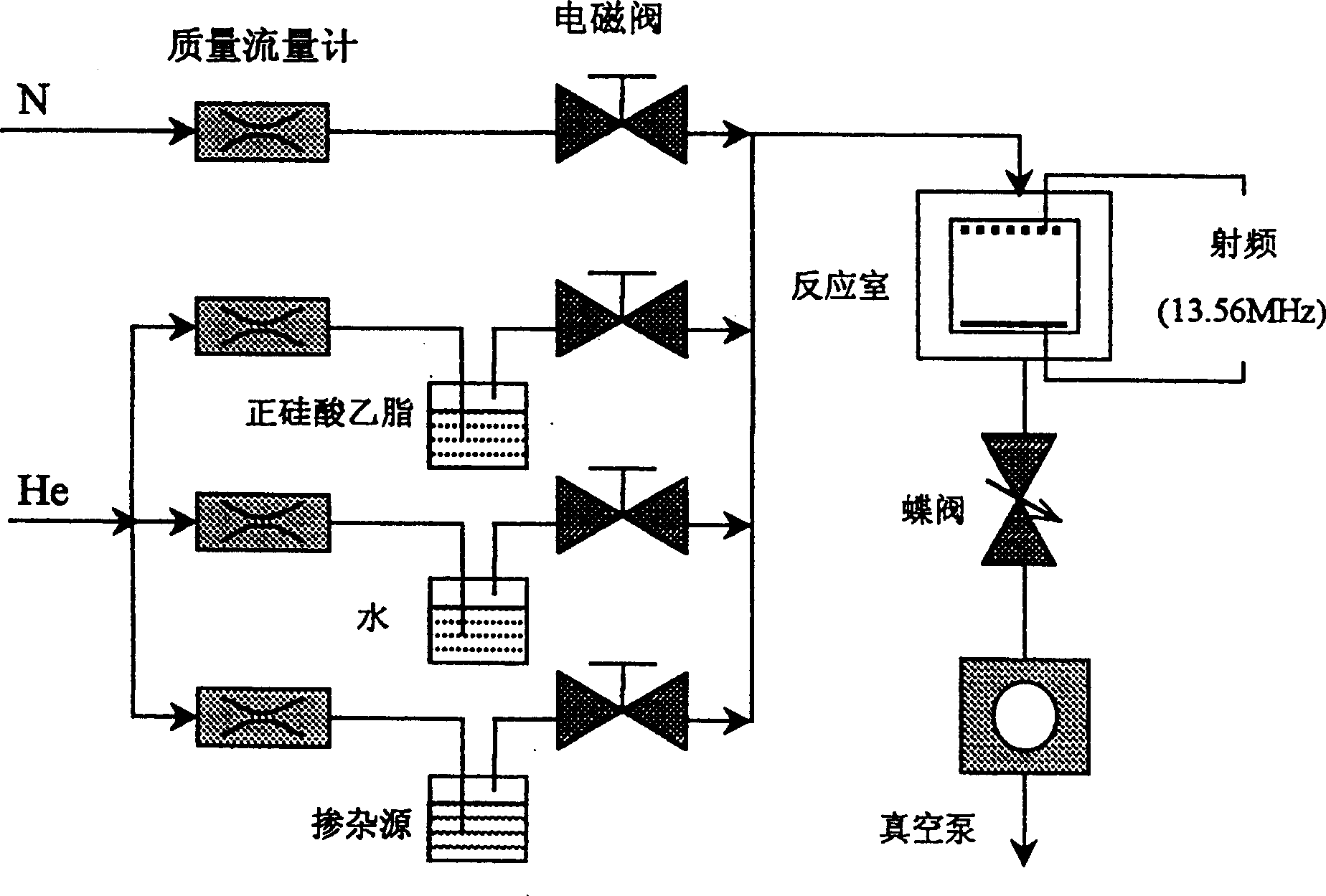

[0015] A two-inch monocrystalline silicon wafer is selected, the surface of the silicon wafer is cleaned according to a conventional cleaning process, and then placed in the reaction chamber after being spin-dried, the reaction chamber is vacuumed to the background vacuum, and the substrate is heated. Heat the source in advance so that TEOS and H 2 O is kept at a constant temperature (30~50℃; 20~30℃). Use He as the carrier gas, and use the bubbling method to combine TEOS and H 2 O was carried into the reaction chamber, and the radio frequency was started. The deposition conditions are shown in Table 1.

[0016] The liquid source is combined with the conventional PECVD technology to prepare the material, and the method used is completely compatible with the current Si integration process. H 2 O-TEOS plasma CVD technology applies the principle of plasma enhancement when forming silicon oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com