Full-component quantitative detection device and method for natural gas containing high-concentration H2S

A quantitative detection and natural gas technology, applied in measurement devices, material separation, analysis of materials, etc., can solve the problems of complex analysis process and long analysis process, improve experimental analysis efficiency, accurate test results, avoid long-term and toxic Effects of harmful gas exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

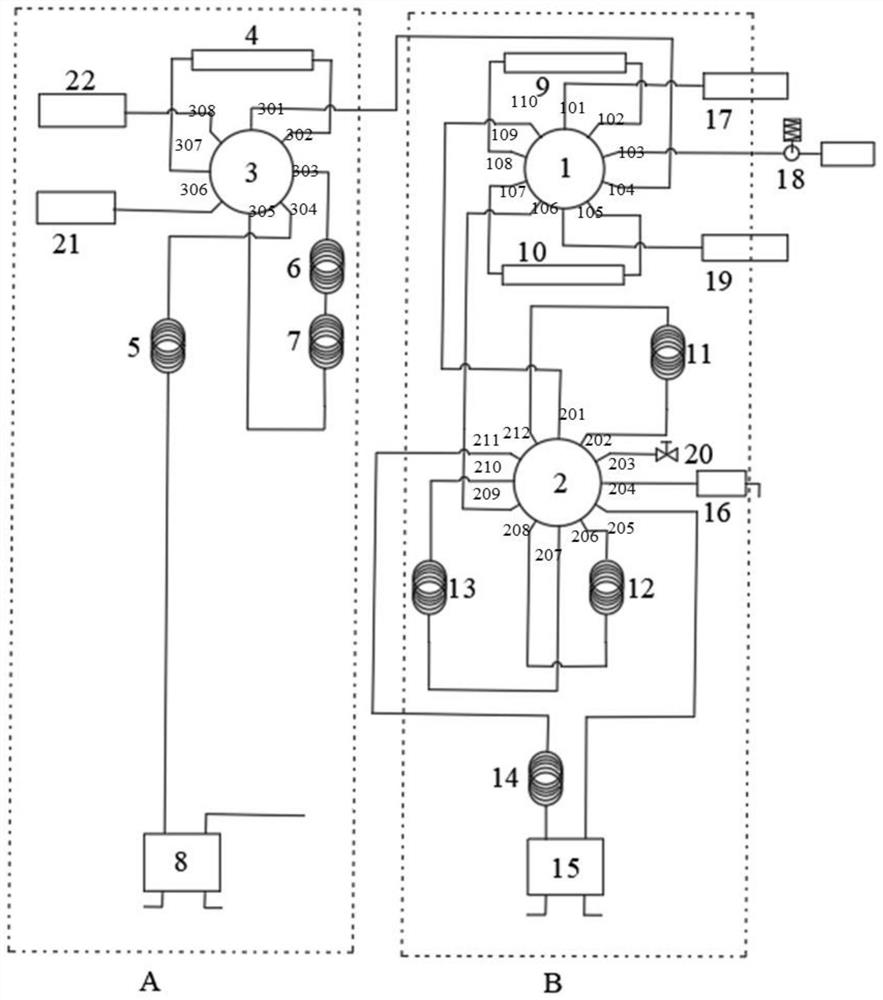

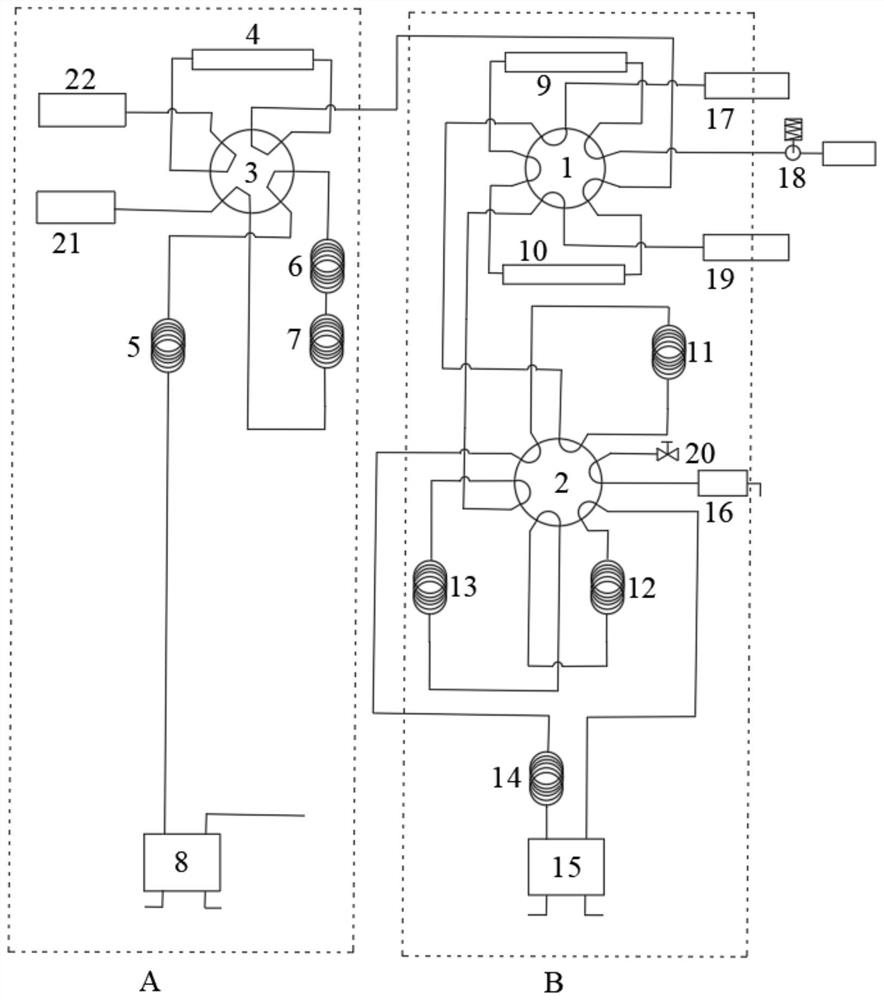

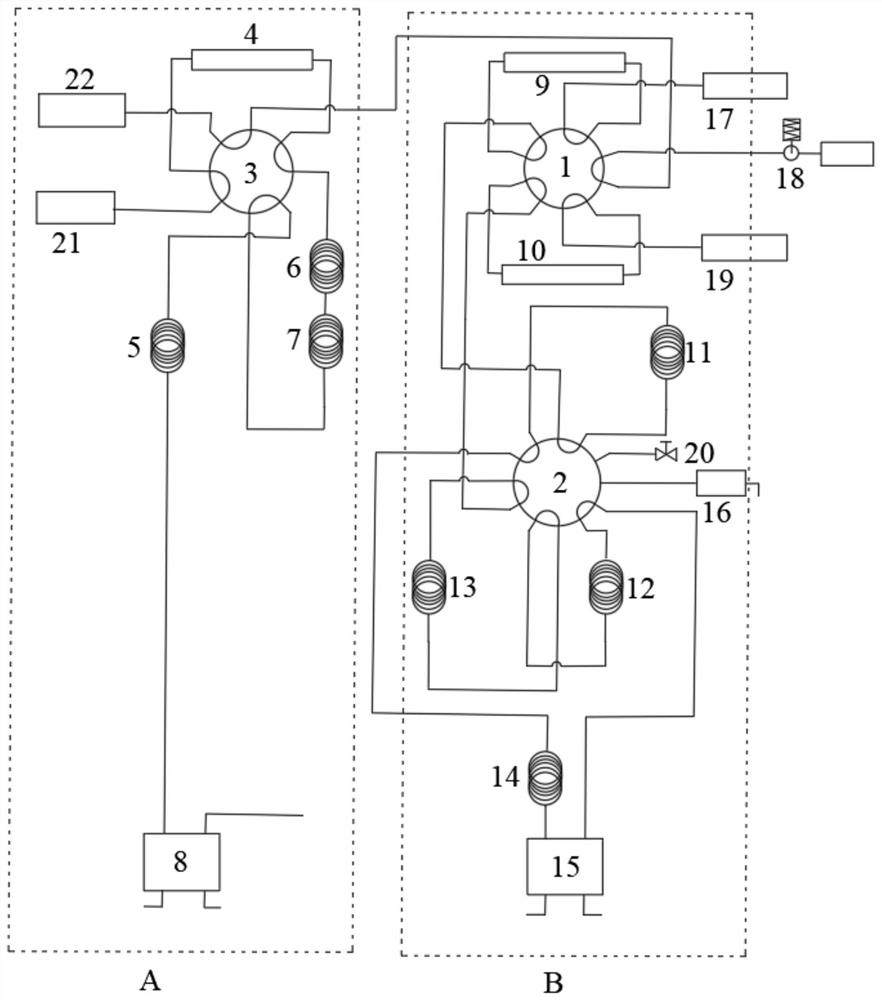

[0079] a H 2 S natural gas full component quantitative detection device, such as Figure 1-4 As shown, it includes a first detection part A and a second detection part B; the first detection part A includes a third connection part 3, a first sample storage part, a first separation part and a first thermal conductivity detector 8, so The first sample storage part, the first separation part, and the first thermal conductivity detector 8 are respectively communicated with the third connection part 3; further, the first detection part A also includes a first buffer column 5, the The first thermal conductivity detector 8 communicates with the third connection part 3 through the first buffer column 5, the first sample storage part includes the first quantitative tube 4, and the first separation part includes a separation column 6 and molecular sieves7. Specifically, the first quantitative tube 4 is a 1mL quantitative tube, the separation column 6 is a HayesepR separation column, w...

Embodiment 2

[0086] Detection of Natural Gas No.1 Sample

[0087] The content of each component in the standard gas: O 2 (0.200%), N 2 (2.00%), C 2 h 6 (2.53%), CO 2 (3.00%), H 2 S (1.49%), C 3 h 8 (2.52%), iC 4 h 10 (0.204%), nC 4 h 10 (0.201%), iC 5 h 12 (0.202%), nC 5 h 12 (0.201%), C 6+ (0.203%), He (0.200%), H 2 (0.199%), CH 4 , (86.889%)

[0088] The specific implementation process of the test includes the following steps:

[0089] S1. Start the device, set the initial state of the device, set the flow rate of carrier gas nitrogen at the first detection part A to 20mL / min, column pressure at 19.3psi, and column temperature at 120°C; set the flow rate of carrier gas helium at the second detection part B to 25mL / min , the chromatographic column pressure is 41psi, the chromatographic column temperature is 130°C, and the device is preheated and stabilized for 1 hour. After the preheating is completed, adjust the ten-way valve and eight-way valve of the device to the...

Embodiment 3

[0101] Natural Gas No. 2 Sample

[0102] The specific detection method of the natural gas No. 2 sample is the same as in Example 2, the only difference being the content of hydrogen sulfide in the natural gas sample.

[0103] In this embodiment, natural gas No. 2 sample is used, and the hydrogen sulfide content in the sample is about 10.00%. The measured data of the natural gas sample are shown in Table 2.

[0104] Table 2 Test data of natural gas No. 2 sample

[0105]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com