Rapid groove broaching equipment for wooden stool plate of woodworking workshop for children

A workshop wooden stool and carpentry technology, which is applied in the field of quick slotting equipment for wooden stool boards in children's wood workshops, can solve the problems of board collapse and injury, board weight, and board flying, so as to weaken the ability of autonomous operation and reduce injuries rate, the effect of increasing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

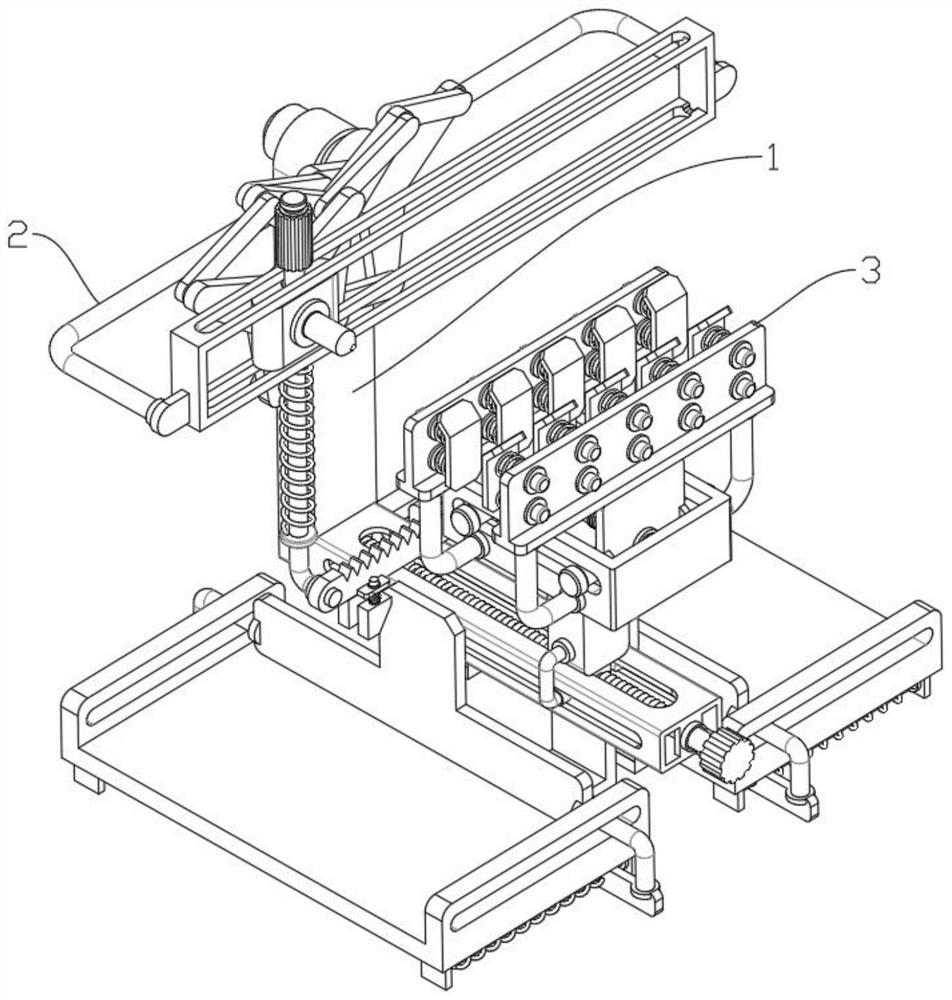

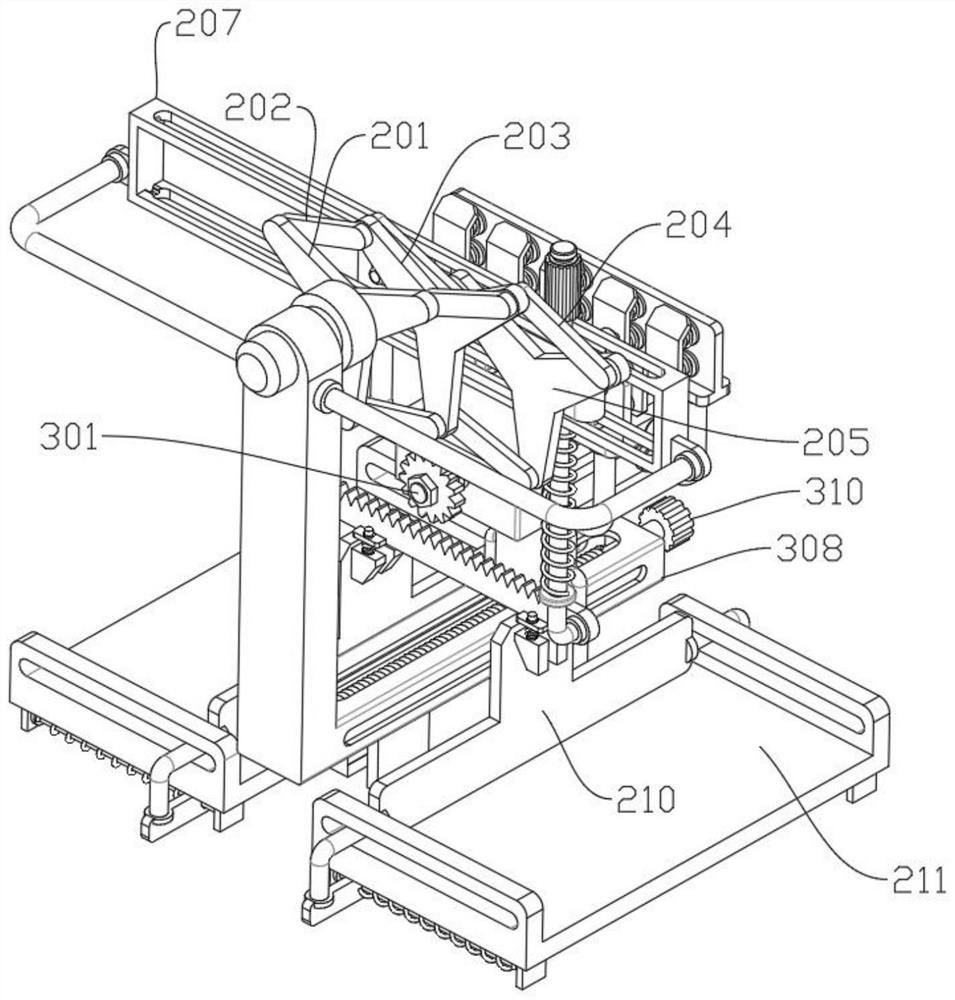

[0029] Please refer to Figure 2 to Figure 6 As shown, a quick slotting equipment for wooden stool boards in children's carpentry workshops, including a support rod 1, the upper end of the support rod 1 is provided with a translation mechanism 2, and the front end of the translation mechanism 2 is provided with a clamping adjustment mechanism 3, and the translation mechanism 2 includes a motor triangular plate 201, the first pull rod 202, the center triangle 203, the second pull rod 204, the drill triangle 205, the motor triangle 201 is uniformly rotated in the diameter and is connected with a plurality of first pull rods 202, and one end of the first pull rod 202 is connected with a center triangle 203, and the center A plurality of second pull rods 204 are uniformly rotated within the diameter of the square plate 203, and one end of the second pull rod 204 is rotatably connected with a drill triangle 205, and the middle end of the drill triangle 205 is rotatably connected wit...

Embodiment 2

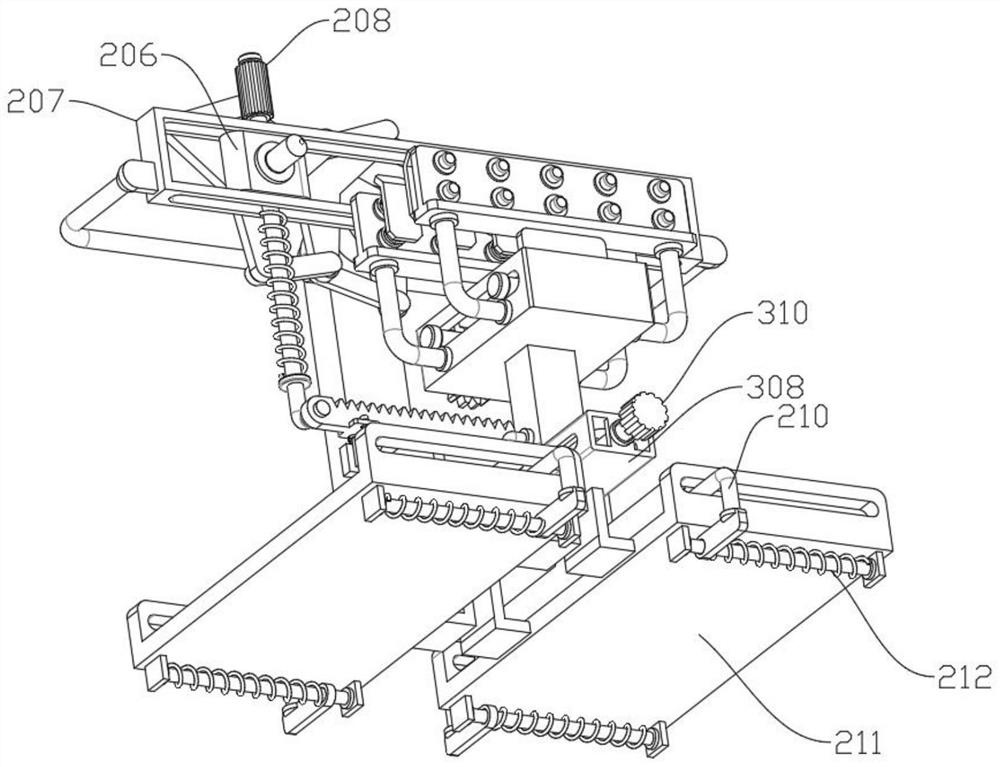

[0032] Please refer to figure 2 and image 3 and Figure 5 and 7 and Figure 8 As shown, the clamping adjustment mechanism 3 includes a power gear 301, a two-way threaded rod 302, a splint 303, and a positioning shell 304. The lower end of the curved spring sawtooth plate 208 is provided with a power gear 301. The left and right ends of the threaded rod 302 are threadedly connected with splints 303, the front and rear ends of the splint 303 are slidingly connected with positioning shells 304, the left and right ends of the positioning shell 304 are fixedly connected with extrusion plates 305, and one end of the extrusion plates 305 is equidistantly slidingly connected There are multiple slopes to extrude the spring plate 306, the lower end of the positioning shell 304 is threadedly connected with a power threaded rod 307, the left end of the power threaded rod 307 is rotatably connected with a hollow positioning chute rod 308, and the left end of the hollow positioning chu...

Embodiment 3

[0035] Please refer to Figure 1 to Figure 8 As shown, a quick slotting equipment for wooden stool boards in children's carpentry workshops, including a support rod 1, the upper end of the support rod 1 is provided with a translation mechanism 2, and the front end of the translation mechanism 2 is provided with a clamping adjustment mechanism 3, and the translation mechanism 2 includes a motor triangular plate 201, the first pull rod 202, the center triangle 203, the second pull rod 204, the drill triangle 205, the motor triangle 201 is uniformly rotated in the diameter and is connected with a plurality of first pull rods 202, and one end of the first pull rod 202 is connected with a center triangle 203, and the center A plurality of second pull rods 204 are uniformly rotated within the diameter of the square plate 203, and one end of the second pull rod 204 is rotatably connected with a drill triangle 205, and the middle end of the drill triangle 205 is rotatably connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com