Antireflection film based on carbon dioxide atmosphere heat treatment and preparation method and application thereof

A carbon dioxide and anti-reflection film technology, applied in the direction of coating, can solve the problems of increasing economic cost, irritating odor, harmful to human body, etc., and achieving the effects of low cost, increased transmittance, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

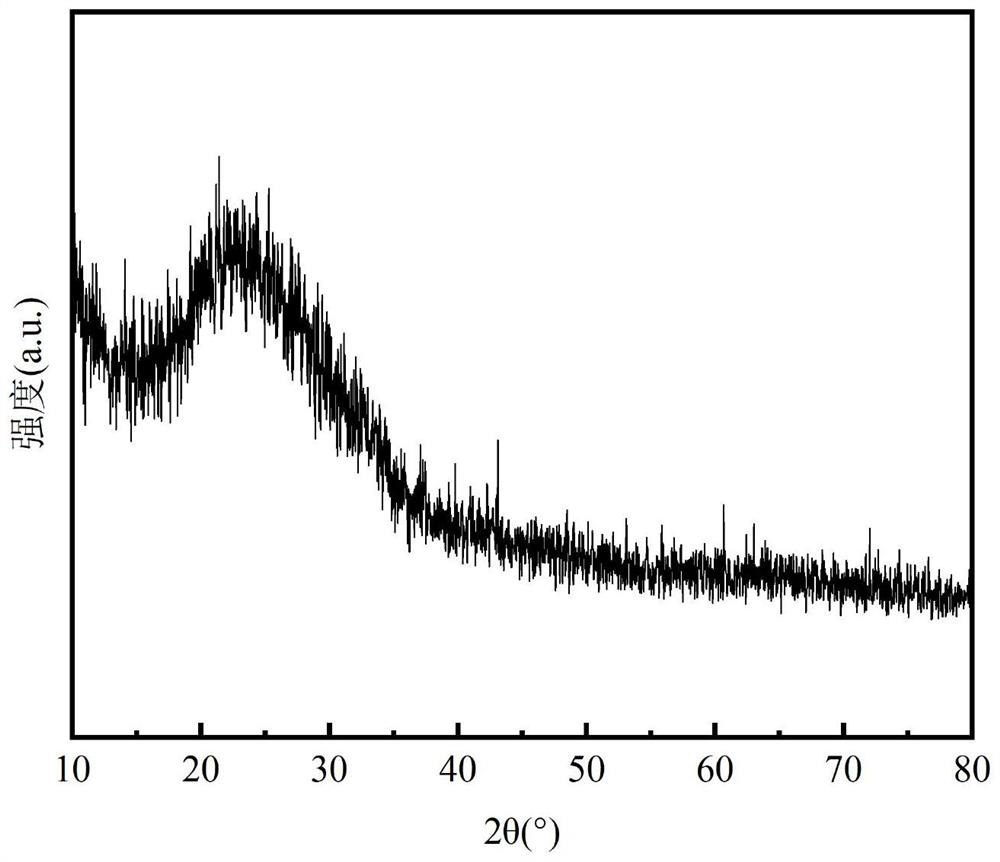

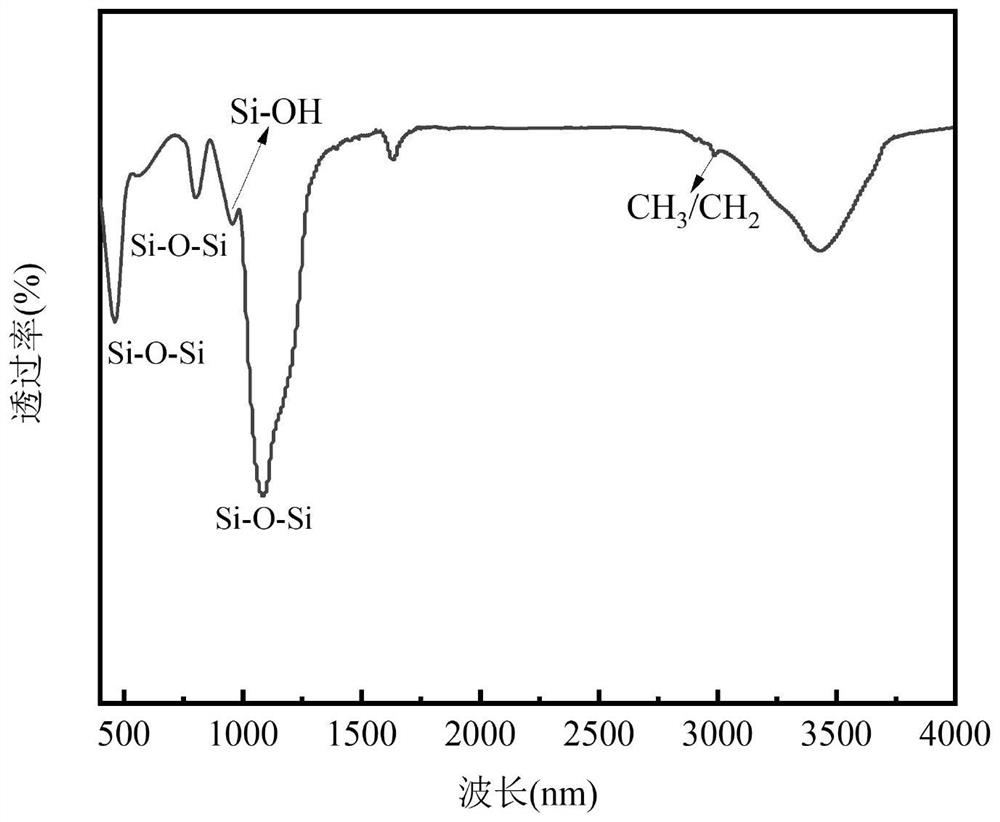

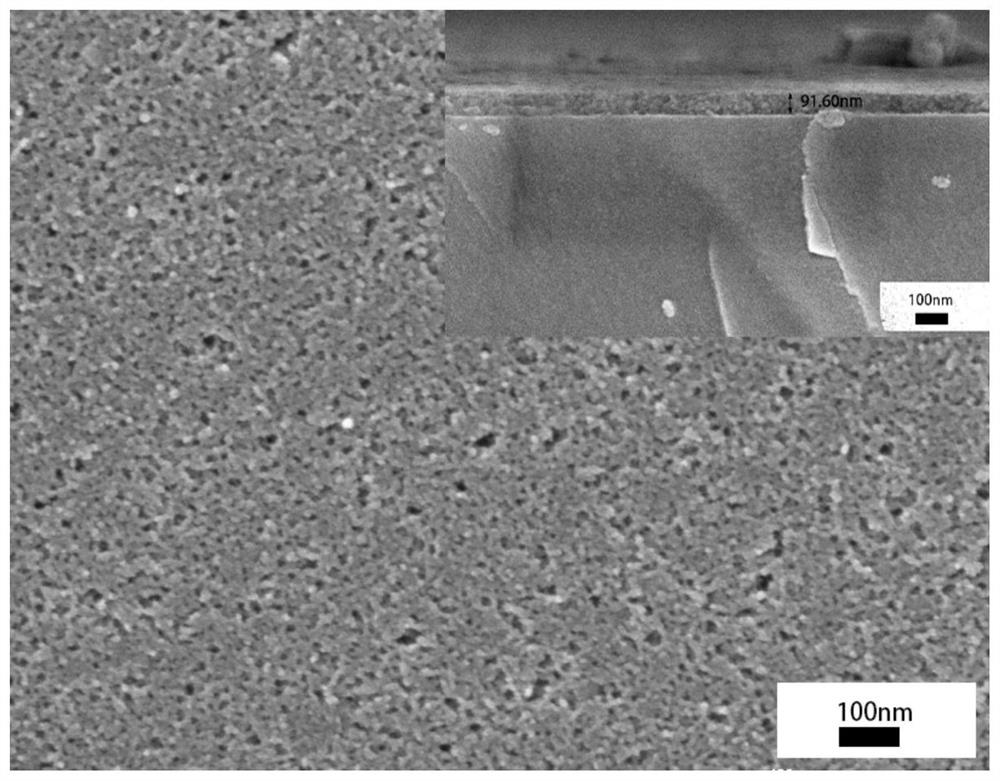

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an anti-reflection film based on carbon dioxide atmosphere heat treatment is provided, comprising the following steps:

[0033] (a) Preparation of SiO 2 Sol: Mix tetraethyl orthosilicate, ethanol, and ammonia water at a molar ratio of 1:47:1, react for 3 hours under magnetic stirring, and then age for 4 days to obtain SiO 2 Sol.

[0034] (b) Cleaning of the glass substrate: The cleaning sequence of the glass slide is to wash the substrate by hand with detergent first, and then use alcohol, acetone, acid solution, and alcohol to ultrasonically clean in sequence, and the ultrasonic time for each time is 30-40min.

[0035] (c) Spin-coating coating on the substrate: the substrate is placed on a spin-coating table, and corresponding parameters are set to form a layer of uniform liquid film on the substrate under the action of centrifugal force. Spin coating only once, and the parameter settings in the spin coating machine are as follows: the first sp...

Embodiment 2

[0039] A method for preparing an anti-reflection film based on carbon dioxide atmosphere heat treatment is provided, comprising the following steps:

[0040] (a) Preparation of SiO 2 Sol: Mix tetraethyl orthosilicate, ethanol, and ammonia water at a molar ratio of 1:47:1, react for 3 hours under magnetic stirring, and then age for 4 days to obtain SiO 2 Sol.

[0041] (b) Cleaning of the glass substrate: The cleaning sequence of the glass slide is to wash the substrate by hand with detergent first, and then use alcohol, acetone, acid solution, and alcohol to ultrasonically clean in sequence, and the ultrasonic time for each time is 30-40min.

[0042] (c) Spin-coating coating on the substrate: the substrate is placed on a spin-coating table, and corresponding parameters are set to form a layer of uniform liquid film on the substrate under the action of centrifugal force. Spin coating only once, and the parameter settings in the spin coating machine are as follows: the first sp...

Embodiment 3

[0046] (a) Preparation of SiO 2 Sol: Mix tetraethyl orthosilicate, ethanol, and ammonia water at a molar ratio of 1:47:1, react for 3 hours under magnetic stirring, and then age for 4 days to obtain SiO 2 Sol.

[0047] (b) Cleaning of the glass substrate: The cleaning sequence of the glass slide is to wash the substrate by hand with detergent first, and then use alcohol, acetone, acid solution, and alcohol to ultrasonically clean in sequence, and the ultrasonic time for each time is 30-40min.

[0048] (c) Spin-coating coating on the substrate: the substrate is placed on a spin-coating table, and corresponding parameters are set to form a layer of uniform liquid film on the substrate under the action of centrifugal force. Spin coating only once, and the parameter settings in the spin coating machine are as follows: the first spin coating speed is 1000r / min, and the time is 5s; the second spin coating speed is 8000r / min, and the time is 20s. Uniform film.

[0049] (d) SiO after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com