Log rotating disk and disk body manufacturing method thereof

A disk and disk technology, applied in wood heating, wood impregnation, manufacturing tools, etc., can solve the problems of lack of use value, etc., and achieve the effect of smooth and fine wood surface, long rotation time, and fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

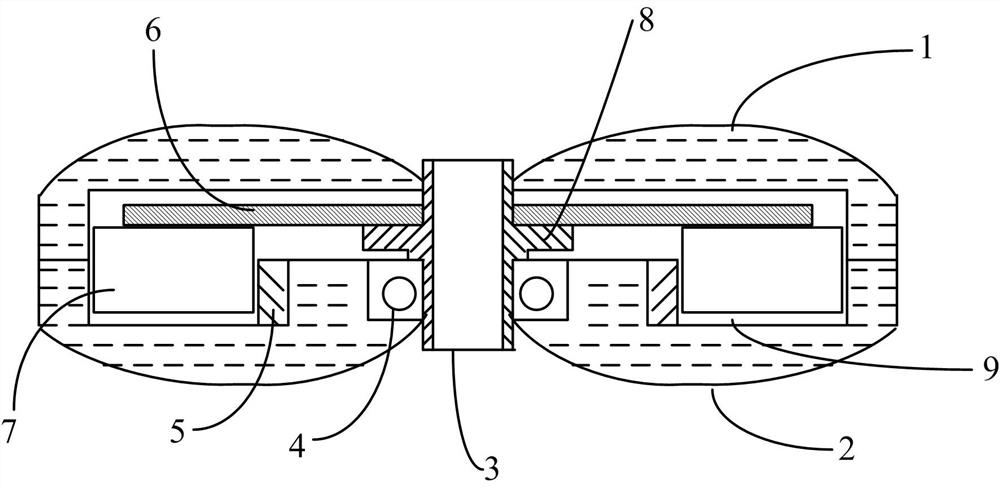

[0025] This embodiment provides a basic structure of a log rotating disk and a manufacturing process of the disk body.

[0026] The production process of the plate includes the following steps: First, choose wood that has been stored for more than two years as raw materials. The six-door wood with a diameter of 20-60mm is cut into discs and short cylinders with a thickness of 20-40mm according to the horizontal grain. Send the short cylinder and disc body into the mold box for drying treatment, the drying temperature is 50°C, and the drying time is 120 hours.

[0027] Secondly, for discs, use methyl methacrylate, dibenzoyl peroxide and trace pigments (not counting), mix them into impregnating glue at a mass ratio of 97.5-98.5:1.5-2.5, and fully impregnate the discs , and put it into a vacuum environment of 0.3MPa for 30min of vacuum infiltration, and then discharge the impregnating glue.

[0028] For the short cylinders, arrange the Liudaomu short cylinders vertically in the...

Embodiment 2

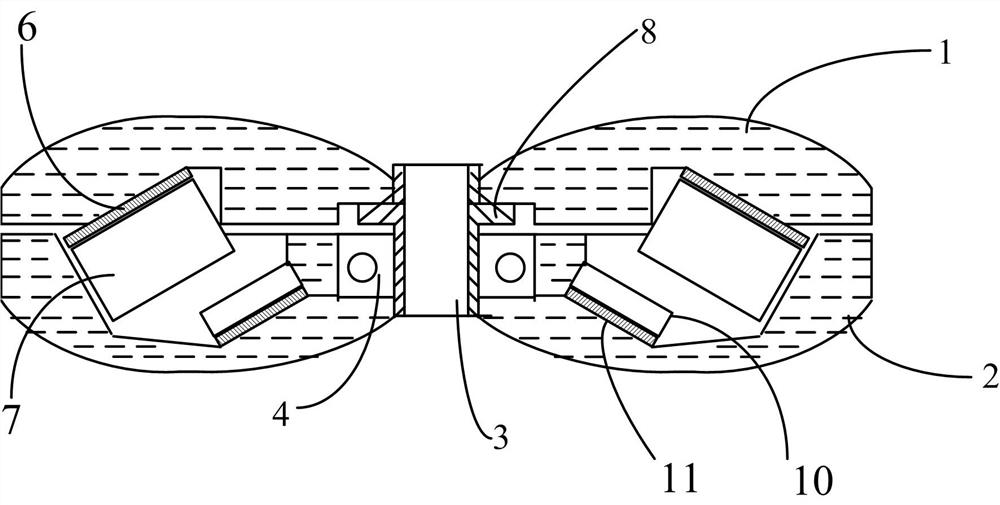

[0033] A kind of manufacturing process of the disk body of the log rotating disk comprises the following steps, first select the trees with cracks such as peaches, plums, walnuts, pears that can bear fruit and six wooden sticks, and cut the trees into a thickness of 2.5-3.5mm, A disc body with a diameter of 200 mm is cut into short cylinders from six-way wood, and placed in a mold box for drying at 60°C and 72 hours.

[0034]Then, for discs, methyl methacrylate and dibenzoyl peroxide are formulated into composition A in a mass ratio of 97.5-98.5:1.5-2.5, and unsaturated polyester, methyl ethyl ketone peroxide and accelerator are formulated by mass The ratio of 98:1.8:0.2 is formulated as composition B, and then composition A and composition B are formulated into impregnated glue with a mass ratio of 3:7, and the heat of unsaturated polyester is used to promote the methylation with physical energy. Curing of Methyl Acrylate. Use dipping glue to impregnate all discs with glue, ...

Embodiment 3

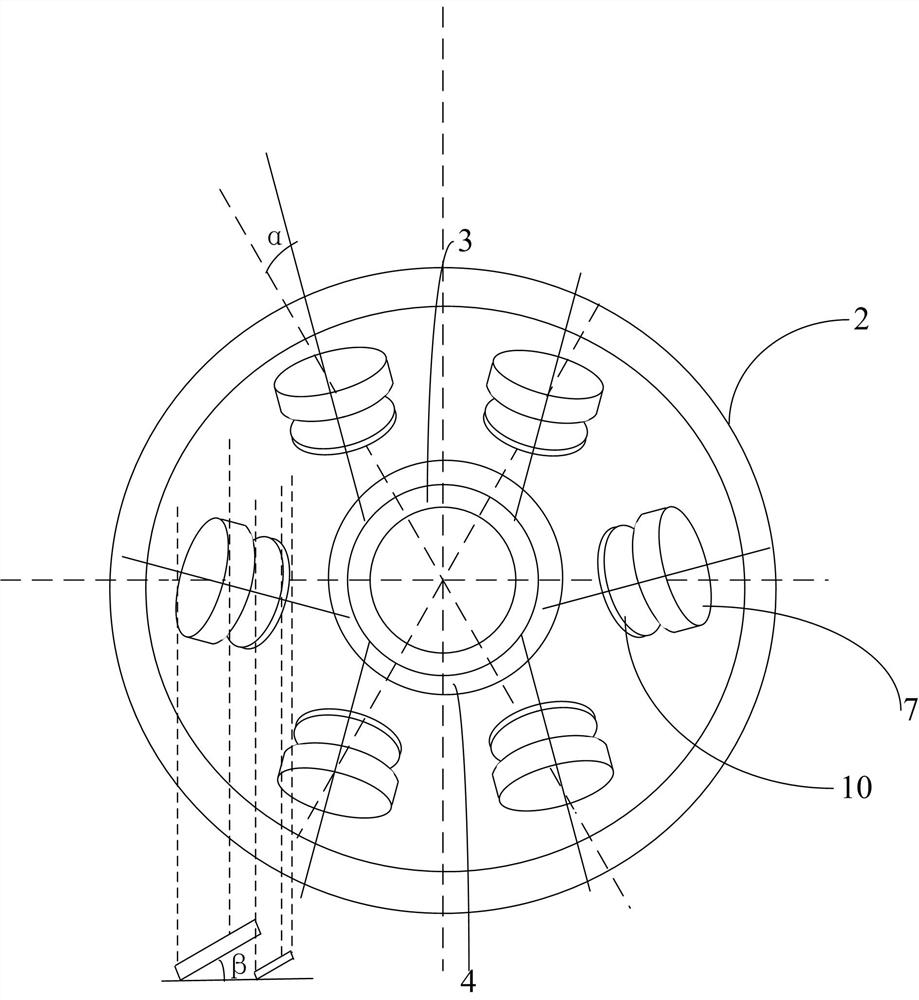

[0039] Use six-dao wood with a diameter of less than 6cm in the mountain forest, and pyrophyllite to make a counterrotating body of six-dao wood and mixture polymerization. The process is: cut the six-dao wood into short columns with a length of 3.5 cm, and place them in the mold box for temperature. 55°C, drying time of 96 hours; use unsaturated polyester, methyl ethyl ketone peroxide and accelerator, according to the mass ratio of 98:1.8:0.2 to prepare impregnated glue, and then use impregnated glue, 20-80 mesh Pyrophyllite and 600-1250 aluminum hydroxide powder are stirred into a coarse mixture in a mass ratio of 2:6:2, covering and filling in vacuum the six-door short columns closely arranged in the combined mold, and the rest are coarsely mixed All materials are sheet-formed.

[0040] The rough mixture is formed by vibration through the Chinese patent "multi-layer combined vacuum stone forming device", the application number is 201110315988.7, the process parameters are: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com