Mineral slow-release fertilizer and preparation method thereof

A slow-release fertilizer and mineral technology, applied in nitrogen fertilizer, phosphate fertilizer, calcareous fertilizer, etc., can solve the problems of poor environmental friendliness, high cost of nitrification inhibitor, difficult to widely use, etc. Dissolution and release effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

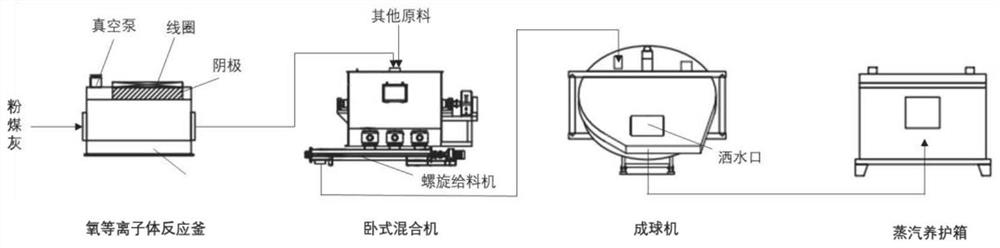

[0031] The invention provides a kind of preparation method of mineral slow-release fertilizer, it is characterized in that, comprises the following steps:

[0032] a) mixing materials: mixing materials to obtain a mixing material;

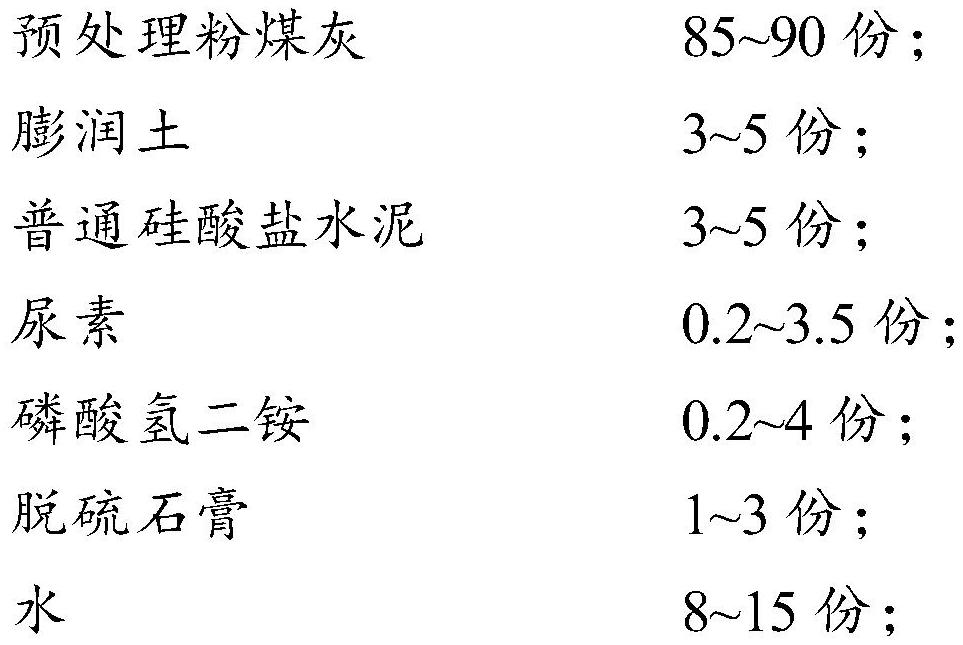

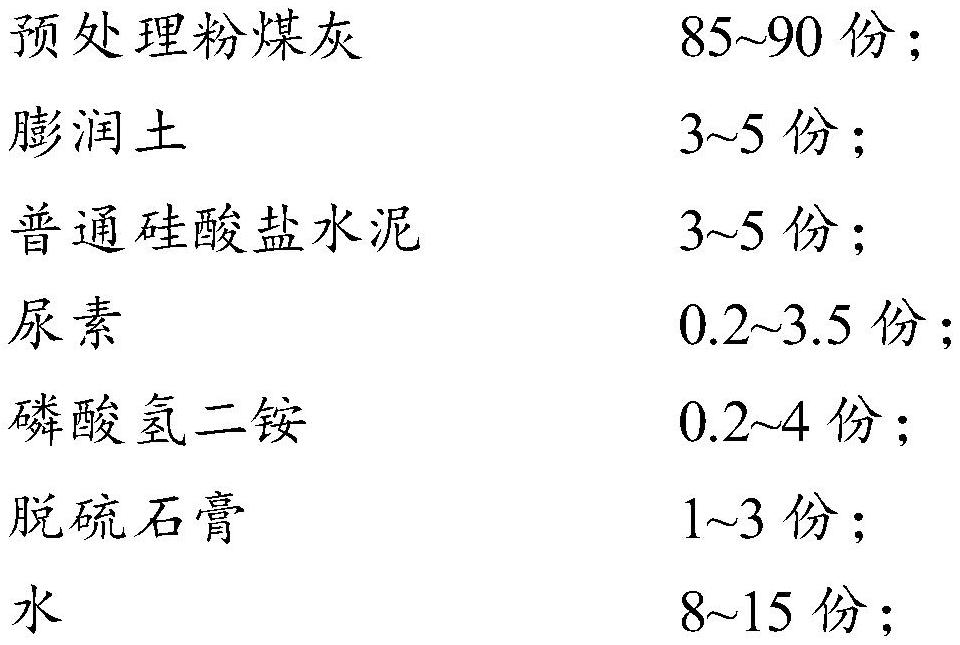

[0033] Described material comprises the component of following mass parts:

[0034]

[0035] Wherein, the pretreated fly ash is plasma pretreated fly ash, which is obtained in the following manner:

[0036] Put the fly ash in the plasma reactor for pretreatment for 10-40 minutes to obtain the pretreated fly ash;

[0037] The power of the plasma treatment is 40-90W, the treatment gas is oxygen, and the flow rate of the treatment gas is 20-60L / min;

[0038] b) Balling and granulation:

[0039] The mixture is granulated into balls to obtain spherical granules;

[0040] c) steam curing:

[0041] The spherical granules are subjected to steam curing to obtain a spherical fly ash-based mineral slow-release fertilizer.

[0042] Regarding step a)...

Embodiment 1

[0078] 1. Raw materials:

[0079]

[0080] Wherein, the pretreated fly ash is plasma pretreated fly ash, obtained by the following method: put the fly ash in a plasma reactor for pretreatment for 20 minutes to obtain the pretreated fly ash;

[0081] The power of the plasma treatment is 60W, the treatment gas is oxygen, and the flow rate of the treatment gas is 40L / min.

[0082] 2. Preparation:

[0083] After the fly ash is pretreated by plasma treatment, it is sent into the horizontal mixer, and other raw materials are also sent into the horizontal mixer, and mixed at 25 rpm for 25 minutes to obtain a mixture. The mixed material enters the screw feeder below, and then is transported by the bucket elevator to the disc ball forming machine. The diameter of the disc ball forming machine is 2m, the inclination angle is 40°, the speed is 30r / min, and the ball forming takes 0.5h During the period, the nozzle of the tray is regularly sprinkled with water, and the total amount of w...

Embodiment 2

[0085] 1. Raw materials:

[0086]

[0087] Wherein, the pretreated fly ash is plasma pretreated fly ash, obtained by the following method: put the fly ash in the plasma reactor for pretreatment for 10 minutes to obtain the pretreated fly ash;

[0088] The power of the plasma treatment is 90W, the treatment gas is oxygen, and the flow rate of the treatment gas is 60L / min.

[0089] 2. Preparation:

[0090] Carry out according to the process of Example 1, the difference is: in the steam curing step, the initial temperature is 60° C., the relative humidity is 80%, the target temperature is 95° C., and the curing is for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com