Ethylene glycol diacetate or propylene glycol diacetate production system and method

A technology of propylene glycol diacetate and ethylene glycol diacetate, which is applied in the field of diol diacetate preparation, can solve problems such as difficult product separation, many by-products, complicated process flow, etc., so as to improve product purity and increase The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

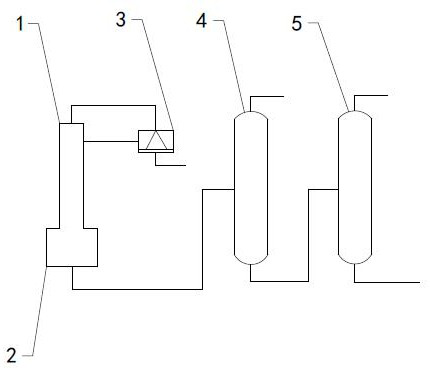

[0022] A production process of ethylene glycol diacetate, according to the formula in parts by weight: 1 part of catalyst, 10-20 parts of ethylene glycol, 20-200 parts of acetic acid, 30-100 parts of water-carrying agent are added to reactor 2, normal pressure, reaction The temperature is 110~150°C, and the reaction is 10~50h; the reacted materials continue to enter the light removal tower 4 from the bottom of the reaction kettle 2, and the light removal tower 4 controls the top temperature of the tower to 110~140°C, and the pressure is normal pressure; the materials obtained from the tower kettle enter Weight removal tower, weight removal tower 5 vacuum degree -0.093~-0.097MPa, control tower top temperature 130~140°C, and get ethylene glycol diacetate at the top of the tower.

[0023] Wherein, filter screen is arranged in reactor 2 to do dividing plate, and the macroporous cation exchange resin catalyst of sulfonic acid treatment is placed above dividing plate; Reactor 2 top c...

Embodiment 8~14

[0029] A kind of propylene glycol diacetate production technology, it is characterized in that: formula according to weight: 1 part of catalyst, 10-20 parts of propylene glycol, 20-200 parts of acetic acid, 30-100 parts of water-carrying agent are added to reactor 2, normal pressure, reaction The temperature is 110~150°C, and the reaction is 10~50h; the reacted material enters the light removal tower 4 from the bottom of the reaction kettle 2, and the light removal tower 4 controls the top temperature of the tower to 110~140°C, and the pressure is normal pressure; the material obtained from the tower kettle enters the light removal tower 4 Heavy tower, weight-removing tower 5 vacuum degree -0.093~-0.097MPa, control tower top temperature 130~140°C, the top of the tower can obtain propylene glycol diacetate, adopt the same production system as in Example 1.

[0030] Wherein, filter screen is arranged in reactor 2 to do dividing plate, and the macroporous cation exchange resin cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com