Novel friction material and preparation method thereof

A friction material, a new type of technology, applied in the field of friction materials, can solve problems such as fracture, poor surface wear resistance and anti-skid performance, and easy cracks on the surface of new friction materials, so as to increase strength, prevent cracks or even breakage, and resist compression good aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] see figure 1 , the present invention provides the following technical solutions: a novel friction material, consisting of the following materials: 5 parts of butanone, 5 parts of toluene, 1 part of nitrile rubber, 0.5 parts of paste resin, 5 parts of polyvinyl chloride, 0.2 parts of white carbon black 0.8 parts, 0.8 parts of zinc oxide, 0.4 parts of stearic acid, 0.1 parts of anti-aging agent, 0.1 parts of calcium carbonate, 1 part of binder, 0.7 parts of initiator, and 8 parts of ceramic fiber.

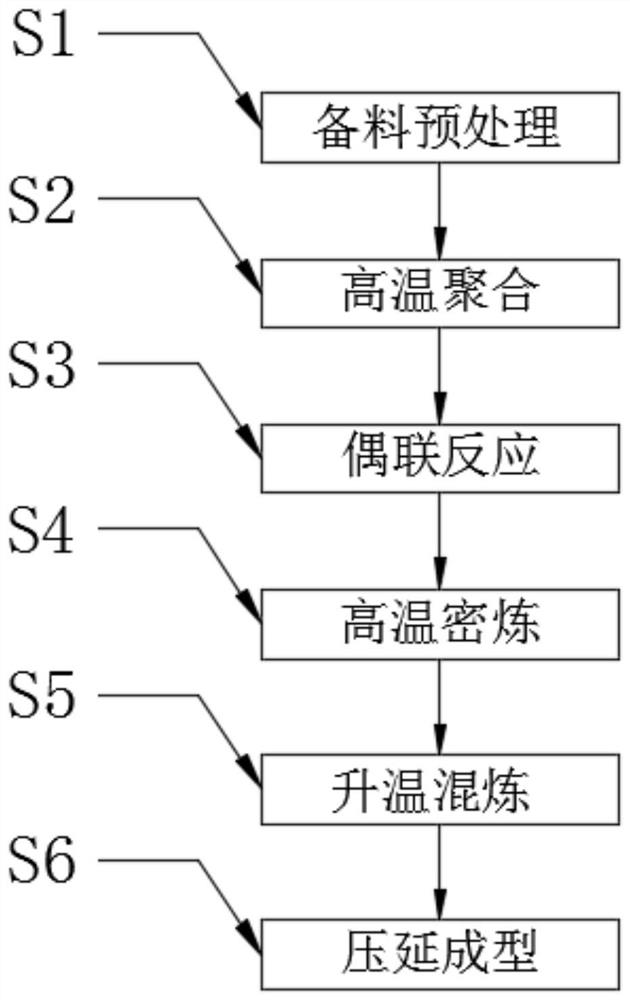

[0028] The present invention also provides a new type of friction material preparation method. The preparation method of degraded plastic particles in the preparation method includes the following steps: S1, weighing for standby, S2, high temperature polymerization, S3, coupling reaction, S4, high temperature banburying, S5 , heating and mixing, S6, calendering, in which:

[0029] S1. Pretreatment of material preparation: Weigh the following materials by weight: 5 parts of me...

Embodiment 2

[0042] see figure 1 , the present invention provides the following technical solutions: a novel friction material, consisting of the following materials: 10 parts of butanone, 10 parts of toluene, 5 parts of nitrile rubber, 1.5 parts of paste resin, 8 parts of polyvinyl chloride, 0.7 parts of white carbon black 1.5 parts of zinc oxide, 1 part of stearic acid, 0.8 parts of anti-aging agent, 0.5 parts of calcium carbonate, 1.5 parts of binder, 1.3 parts of initiator, and 15 parts of ceramic fiber.

[0043] The present invention also provides a new type of friction material preparation method. The preparation method of degraded plastic particles in the preparation method includes the following steps: S1, weighing for standby, S2, high temperature polymerization, S3, coupling reaction, S4, high temperature banburying, S5 , heating and mixing, S6, calendering, in which:

[0044] S1. Pretreatment of material preparation: Weigh the following materials by weight: 10 parts of butanone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com