Visual vacuum cathode magnetic filtering device

A magnetic filtration and cathode technology, applied in vacuum evaporation plating, metal material coating process, coating, etc., can solve the problems of a large number of simulation analysis cost investment, no visualization equipment, limited monitoring means, etc., to achieve visual detection Data, and update process design, improve the effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

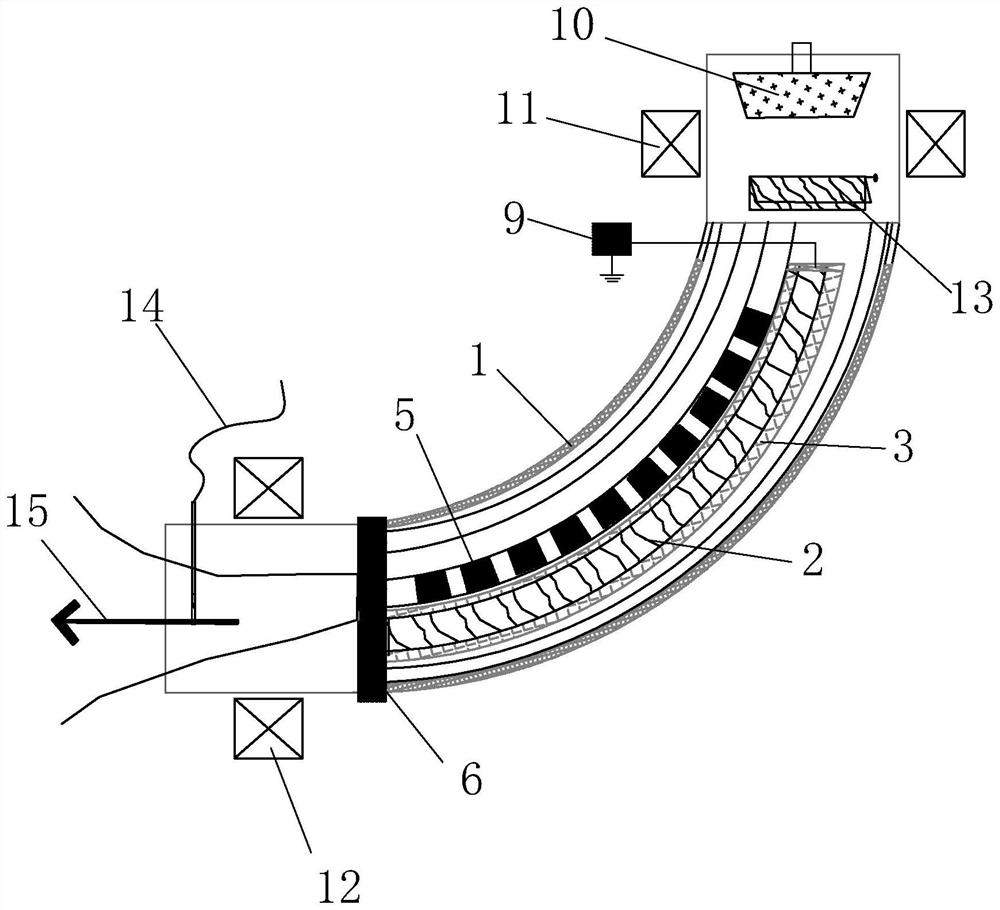

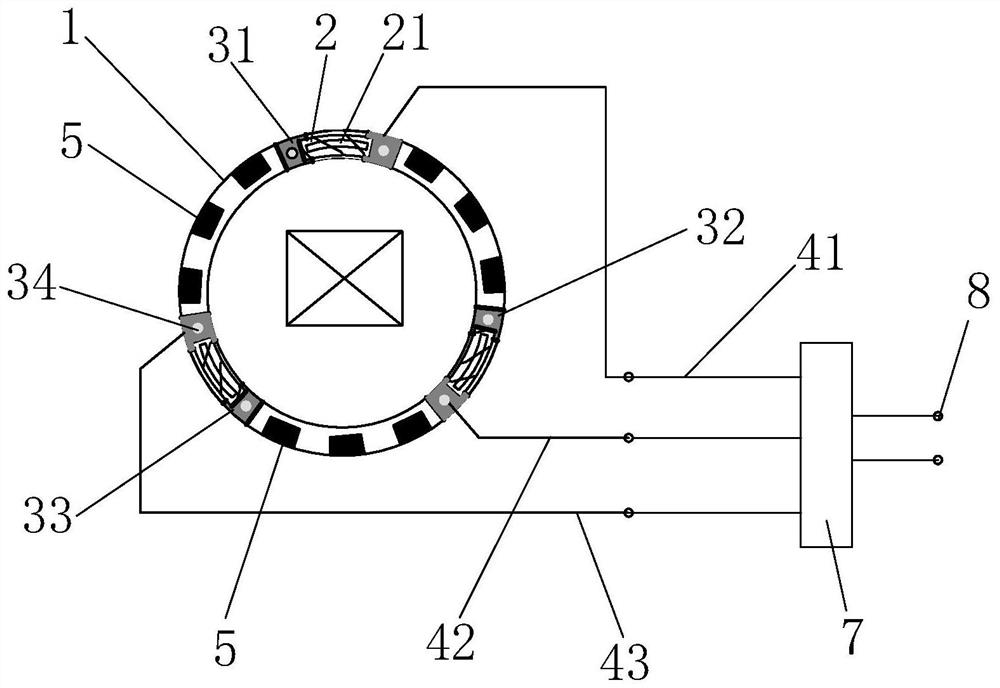

[0026] like Figure 1 to Figure 2 As shown, the embodiment of the present invention is a visual vacuum cathode magnetic filter device, which includes a pipeline 1, and at least one first inlay opening is opened on the pipeline 1, and a transparent plate 2 is embedded on the first inlay opening. The plate 2 extends along the length direction of the pipeline 1, and the transparent plate 2 is sealed and fixed relative to the first inlay opening. The transparent plate 2 and the inlay opening are specifically fastened by screws or fixed by clamps. The transparent plate 2 is double-layered. Transparent structure, the transparent plate 2 includes an inner transparent plate and an outer transparent plate, the space between the inner transparent plate and the outer transparent plate forms a first cooling water channel 21, and the outer transparent glass A water inlet and a water outlet are provided on the plate, and the water inlet and water outlet communicate with the first cooling wa...

Embodiment 2

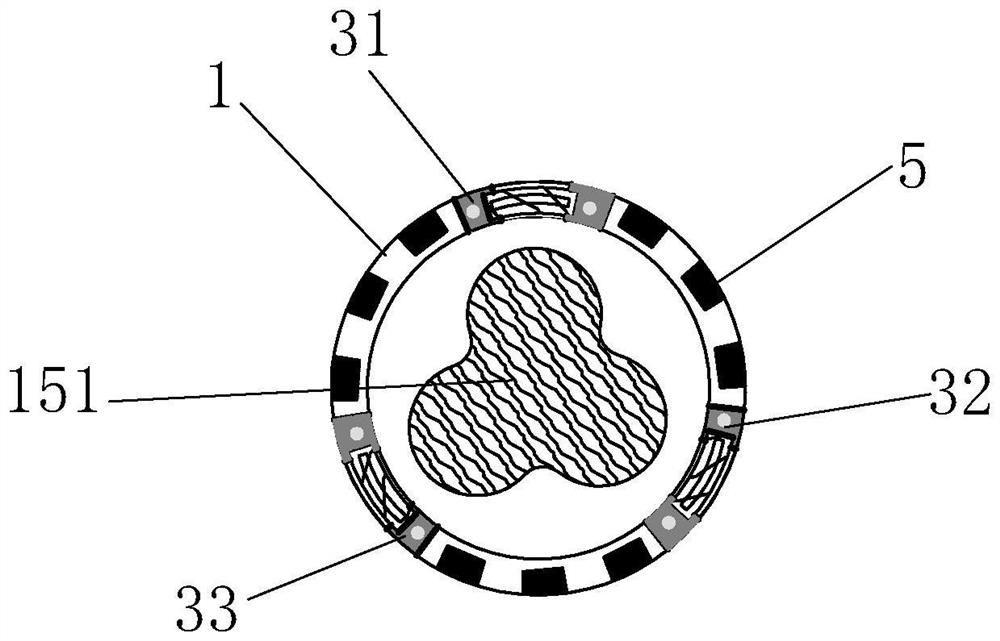

[0042] like Figure 4 to Figure 5 As shown, the embodiment of the present invention is a visualized vacuum cathode magnetic filter device, which includes a pipeline 101, and at least one first inlay opening is opened on the pipeline 101, and a transparent plate 102 is embedded on the first inlay opening. The plate 102 extends along the length direction of the pipe 101, and the transparent plate 102 is sealed and fixed relative to the first inlay opening. The transparent plate 102 and the first inlay opening are specifically fastened with screws or fixed with a clamp. Double-layer transparent structure, the transparent plate 102 includes an inner layer transparent plate and an outer layer transparent plate, the space between the inner layer transparent plate and the outer layer transparent plate forms a first cooling water channel 1021, the outer layer A water inlet and a water outlet are provided on the transparent glass plate, and the water inlet and water outlet communicate ...

Embodiment 3

[0059] An embodiment of the present invention is a visualized vacuum cathode magnetic filter device, which includes a pipeline, and at least one first inlay opening is opened on the pipeline, and a transparent plate is embedded on the first inlay opening, and the transparent plate extends along the direction of the pipeline. The transparent plate and the inlay opening are relatively sealed and fixed, and the transparent plate and the inlay opening are specifically fastened by screws or fixed by clamps. The transparent plate has a double-layer transparent structure, and the transparent plate includes an inner transparent plate and an outer transparent plate. layer transparent plate, the space between the inner layer transparent plate and the outer layer transparent plate forms a first cooling water channel, and the outer layer transparent glass plate is provided with a water inlet and a water outlet, and the water inlet and outlet The water port communicates with the first cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com