Combustor capable of achieving sufficient combustion and using method thereof

A full combustion, burner technology, applied in the combustion method, solid fuel combustion, combustion equipment and other directions, can solve the problems of affecting the combustion effect, easy dust clogging, poor fuel usage rate, etc., to improve the convenience of feeding and ensure combustion. Efficiency, improved uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

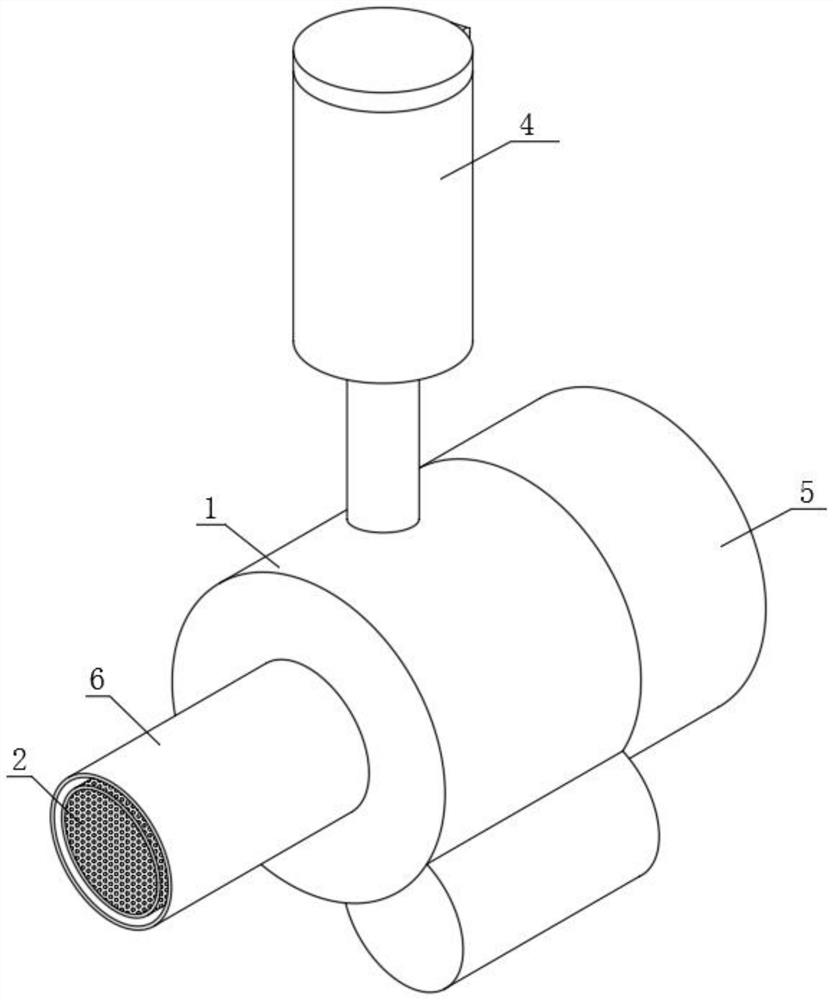

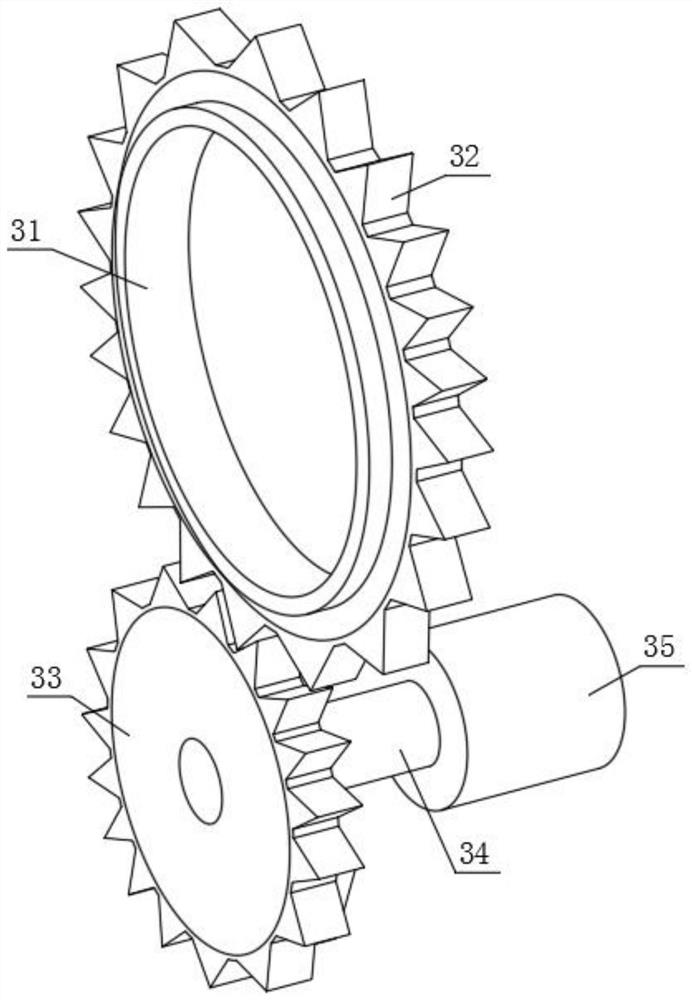

[0038] see figure 1, a fully combustible burner and its use method, comprising a casing 1, a combustion device 2 is arranged inside the casing 1, a transmission assembly 3 is sleeved on one end of the combustion device 2, and a feeding material is connected to the rear of the combustion device 2 Device 4, the rear of the feeding device 4 is provided with an air blowing device 5, one end of the air blowing device 5 is connected to one end of the combustion device 2, and the front end of the combustion device 2 is provided with a dust removal device 6.

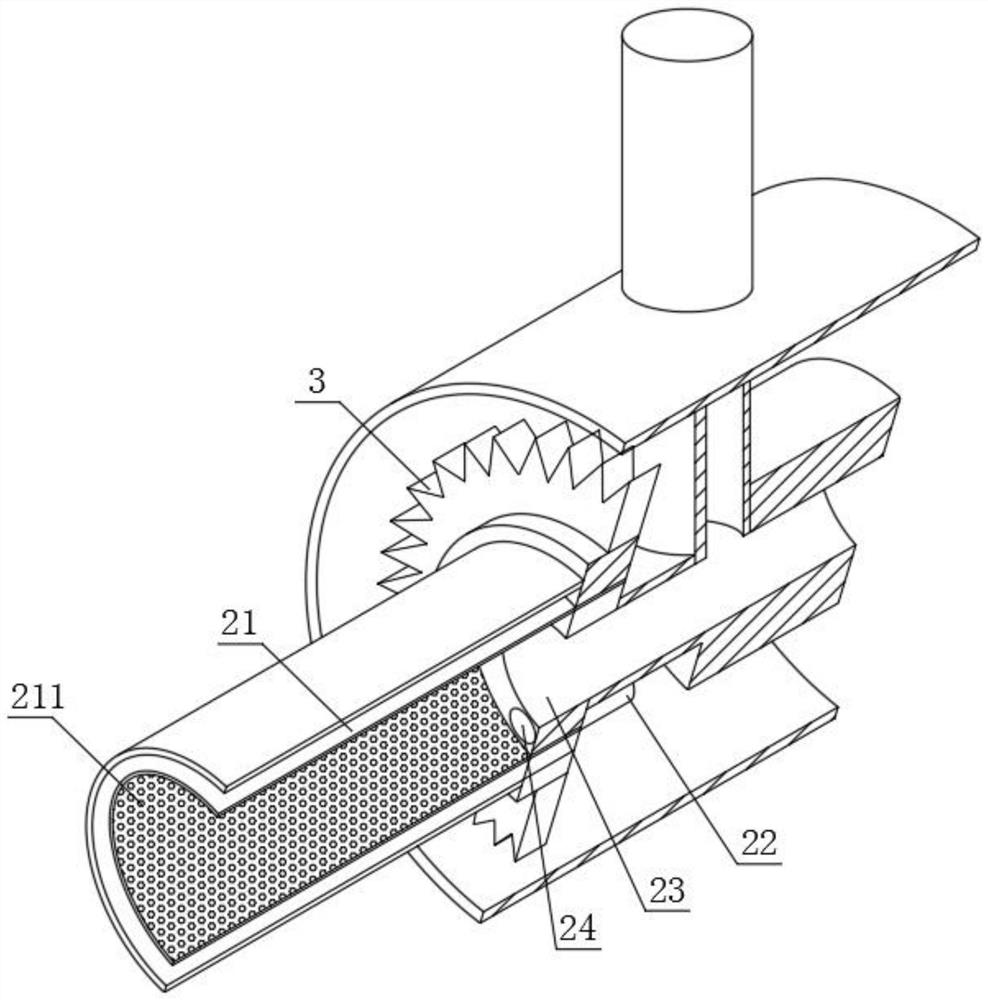

[0039] see figure 2 , the combustion device 2 comprises a combustion pipeline 21, a burner 22, a material port 23 and a combustion port 24, the bottom center of the combustion channel 21 is provided with a material port 23, and the bottom of the combustion channel 21 below the material port 23 is provided with a combustion port 24 , a burner 22 is provided in the combustion port 24, an ash discharge port 211 is provided on the...

Embodiment 2

[0050] see Figure 7-Figure 8 , the top of the cleaning device 6 is also provided with a gas processing device 7, the gas processing device 7 includes a gas outlet pipe 71, a processing tank body 72, a built-in tank body 73 and a processing assembly 74, and the gas outlet pipe 71 communicates with the dust cleaning device 6, and the gas outlet pipe 71 communicates with the cleaning device 6. The top of the air pipe 71 communicates with the built-in tank body 73, the processing tank body 72 is sleeved on the outside of the built-in tank body 73, a heat exchange tank 731 is opened between the processing tank body 72 and the built-in tank body 73, and the inside of the built-in tank body 73 A processing assembly 74 is provided. The processing assembly 74 includes an impurity filter plate 741, an adsorption layer 742 and an exhaust pipe 743. The impurity filter plate 741 is arranged inside the built-in tank body 73, and two layers of adsorption layers 742 are arranged above the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com