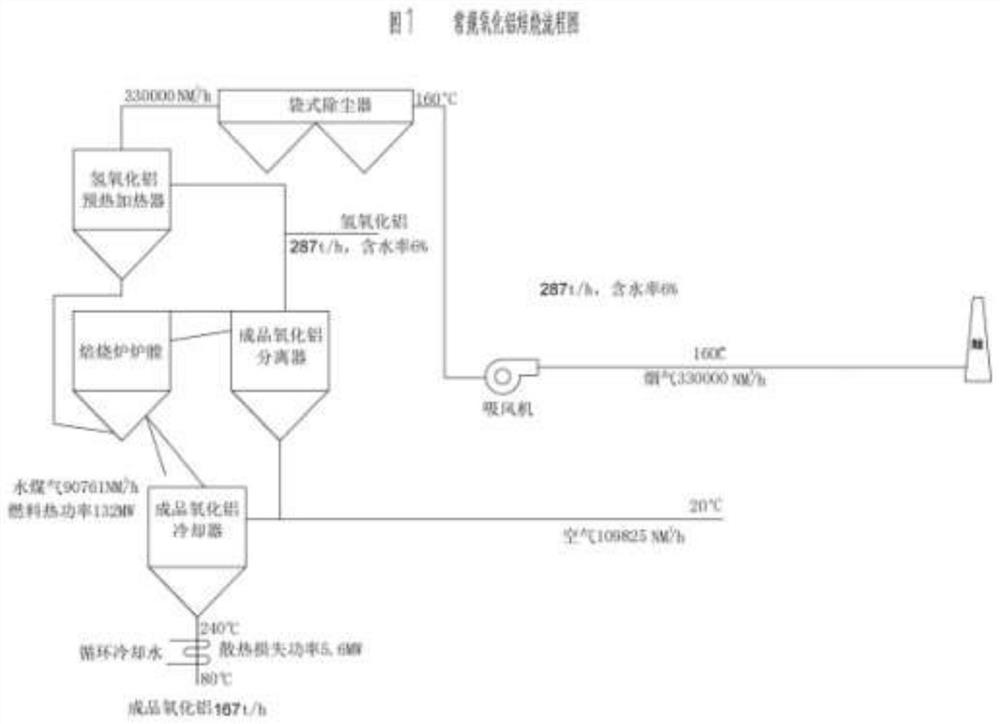

Air backheating and multi-stage waste heat recovery method for aluminum oxide gaseous roasting furnace

A waste heat recovery and roasting furnace technology, applied in furnaces, furnace components, waste heat treatment, etc., can solve the problems of low roasting furnace efficiency, large moisture content, high exhaust gas temperature, etc., to reduce the temperature of the furnace, increase the temperature and humidity, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

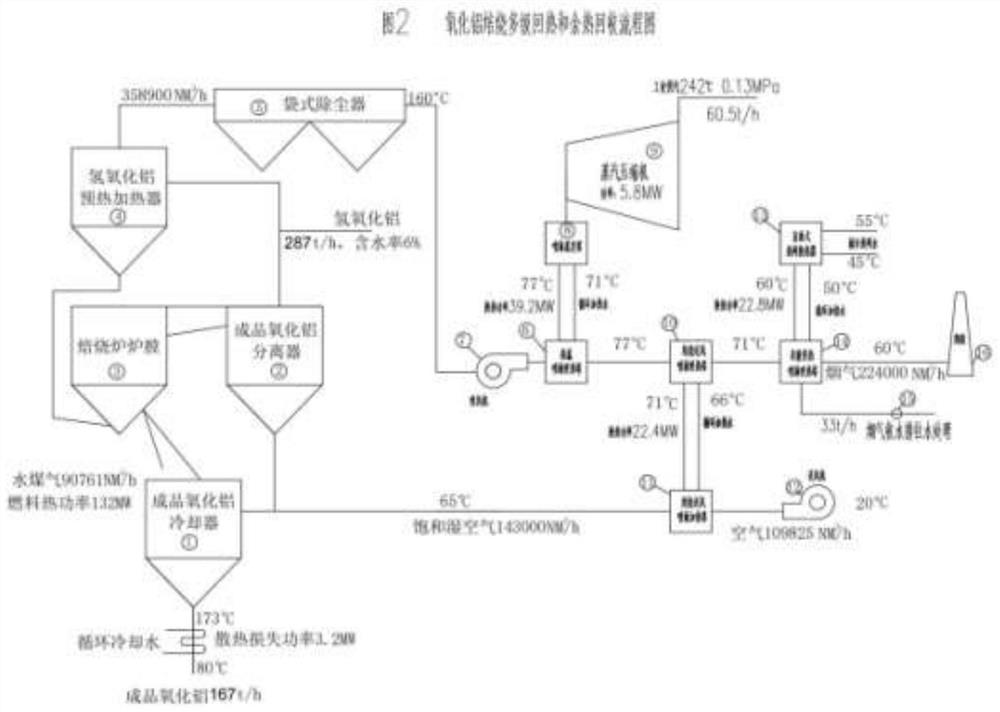

[0041] Aiming at a gaseous alumina roaster with a daily production capacity of 4000 tons, aluminum hydroxide external water of 6%, water gas fuel of 90700 standard cubic meters per hour, and fuel calorific value of 1250Kcal per standard cubic meter, the present invention is described according to the above working conditions.

[0042] A method for air reheating and multi-stage waste heat recovery of an alumina gaseous roaster includes:

[0043] Step A: Process flow of gaseous roaster flue gas high-temperature spraying heat recovery:

[0044] A1: The flue gas flow rate from the gaseous roaster is 359,000 standard cubic meters per hour, and the temperature is 160 ° C. In the high-temperature spray heat absorption tower, it is directly mixed with the cooling water from the spray evaporation tower to 71 ° C. The temperature of the flue gas is reduced to 77°C;

[0045] A2: The temperature of the flue gas from the gaseous roaster lowers the water vapor in the flue gas into condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com