Composite sensor for monitoring tensile strain vector and preparation method thereof

A composite sensor and tensile strain technology, applied in the field of intelligent sensing, can solve the problems of lack of irregular strain size and direction vector detection ability, and achieve the effects of improving detection accuracy, easy preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

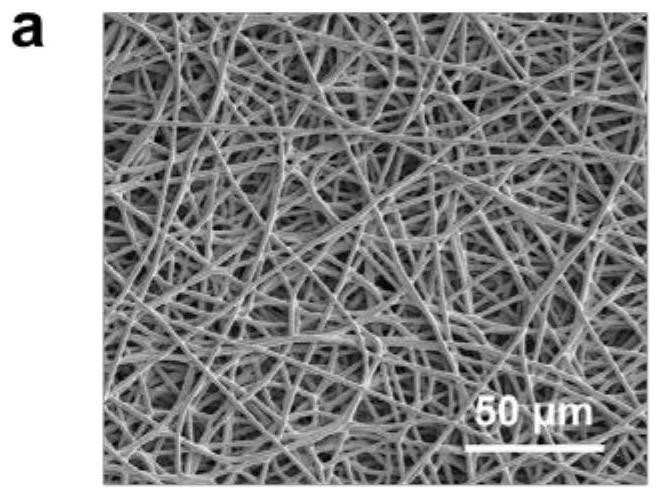

[0041] The preparation process of the top encapsulation layer, the bottom encapsulation layer and the insulating layer (isotropic functional layer) in the embodiment of the present invention is as follows:

[0042] (1) Weigh 2.0 g of polyurethane granules, 3.2 g of dimethylformamide, and 4.8 g of tetrahydrofuran into a glass bottle, put them into a magnet and stir to dissolve. During the dissolution process, the speed is 600 rpm, the heating temperature is 60 °C, and the magnetic stirring time After stirring, the polyurethane solution was allowed to stand for 2 hours to remove internal air bubbles.

[0043] (2) The stretchable substrate of the sensing layer was prepared by the electrospinning process. During the electrospinning process, the electrospinning voltage was set to 20 kV, the feeding volume was 0.6 ml / h, and the receiving drum speed was 100 rpm. The spinning time was 8 hours. After electrospinning, the polyurethane fiber substrate was peeled off from the aluminum foil...

Embodiment 2

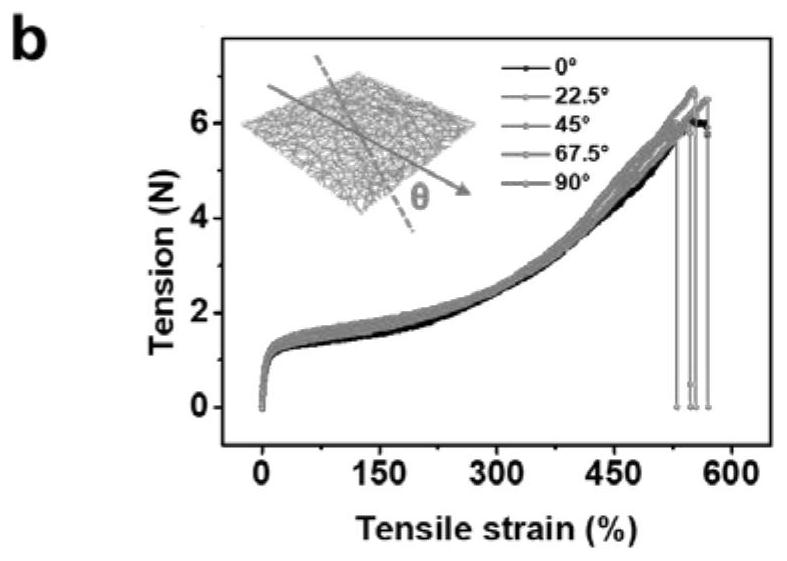

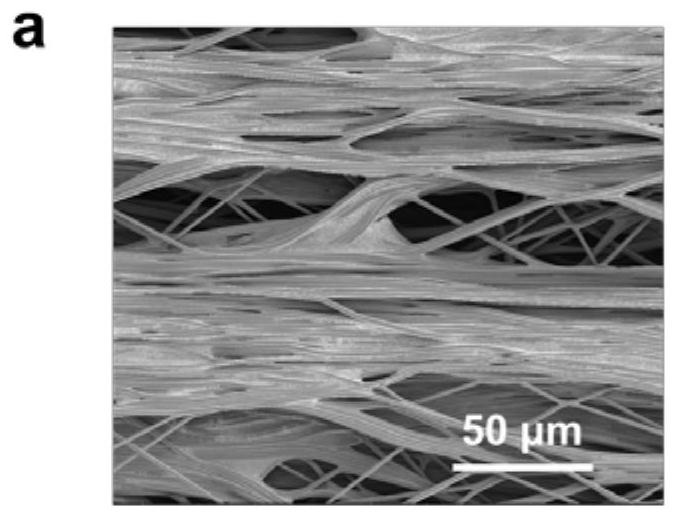

[0046] The preparation process of the anisotropic sensing layer is as follows:

[0047] (1) Weigh 2.0 g of polyurethane granules, 3.2 g of dimethylformamide, and 4.8 g of tetrahydrofuran into a glass bottle, put them into a magnet and stir to dissolve. During the dissolution process, the speed is 600 rpm, the heating temperature is 60 °C, and the magnetic stirring time After stirring, the polyurethane solution was allowed to stand for 2 hours to remove internal air bubbles.

[0048] (2) The stretchable substrate of the sensing layer was prepared by the electrospinning process. During the electrospinning process, the electrospinning voltage was set to 20 kV, the feeding volume was 0.6 ml / h, and the receiving drum speed was 2500 rpm. The spinning time was 8 hours. After electrospinning, the polyurethane fiber substrate was peeled off from the aluminum foil in deionized water, transferred to a polytetrafluoroethylene plate for vacuum drying, and the drying temperature was set at...

Embodiment 3

[0052] The preparation process of a composite sensor for tensile strain vector detection according to the embodiment of the present invention is as follows:

[0053] (1) Weigh 2.0 g of polyurethane granules, 3.2 g of dimethylformamide, and 4.8 g of tetrahydrofuran into a glass bottle, put them into a magnet and stir to dissolve. During the dissolution process, the speed is 600 rpm, the heating temperature is 60 °C, and the magnetic stirring time After stirring, the polyurethane solution was allowed to stand for 2 hours to remove internal air bubbles.

[0054] (2) The top encapsulation layer, bottom encapsulation layer and spacer layer were prepared by electrospinning process. During the electrospinning process, the electrospinning voltage was set to 20 kV, the feed rate was 0.6 ml / h, and the speed of the receiving drum was 100 rpm , and the electrospinning time was 8 hours. After electrospinning, the polyurethane fiber film was peeled off from the aluminum foil in deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com