Production method of rough surface acid continuous rolling hot rolling pickling plate

A technology of hot-rolled pickling and production methods, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of being unable to meet the needs of releasing abundant production capacity and low prices, and achieve the expansion of product categories, low risk, and The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

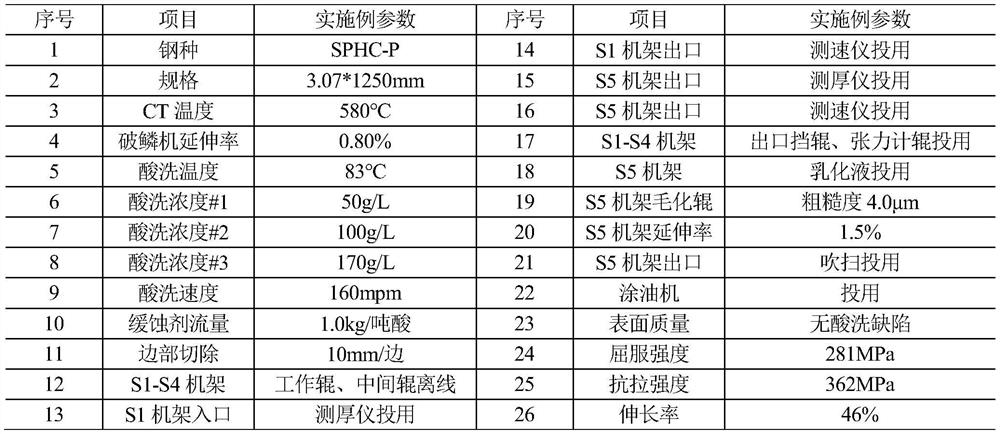

[0035] The production method of rough-faced hot-rolled pickled board in the embodiment of the present invention is completed on the pickling mill. The specific process is: the hot-rolled raw material with a CT temperature of 580 ° C and a thickness of 3.0 mm is sequentially decoiled, laser welded, stretched, scaled, and stretched. Pickling, rinsing, drying, trimming, rolling, oiling, coiling. After breaking scales, pickling, rolling, and oiling, the surface quality and performance of the inspected products meet the national standards. Table 1 is the production method and product inspection results of the embodiment of the present invention.

[0036] The production method of the embodiment of the present invention and product inspection result of table 1

[0037]

[0038] Note: The main component of pickling corrosion inhibitor is alcohol ionic condensate.

[0039] The production method of the rough surface pickling board of the present invention is reasonable in design, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com