Cement grinding aid and preparation method thereof

A technology of cement grinding aids and catalysts, applied in the field of cement additives, can solve problems such as corrosion of concrete steel bars, affecting the service life and durability of concrete, and achieve the effects of improving early strength performance, good environmental protection benefits, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

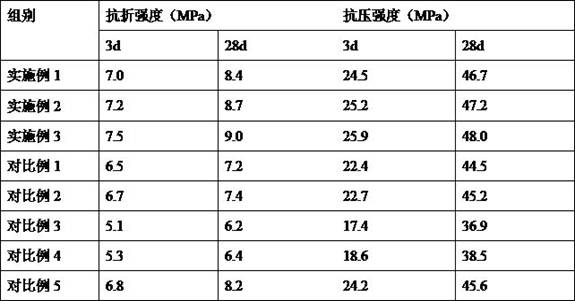

Examples

Embodiment 1

[0033] The present embodiment provides a kind of preparation method of cement grinding aid, comprises the following steps:

[0034] (1) Preparation of polydopamine / catechol modified chitosan powder, the method is as follows:

[0035] S1. Preparation of catechol-modified chitosan: 100 parts by weight of chitosan is dissolved in 200 parts by weight of 10wt% acetic acid solution, then NaOH solution of 1mol / L is added to adjust the pH value to 5, and 100 parts by weight of Add 15 parts by weight of an aqueous solution of 3,4-dihydroxyphenylacetic acid into the above solution, dropwise add 20 parts by weight of a 30wt% ethanol aqueous solution containing 0.5 parts by weight of EDC and 0.5 parts by weight of NHS, stir for 7 hours, and filter. Washing to obtain catechol-modified chitosan;

[0036]S2. Preparation of polydopamine / catechol-modified chitosan: add 100 parts by weight of catechol-modified chitosan prepared in step S1 to 200 parts by weight of water, 1000W ultrasonic dispe...

Embodiment 2

[0040] The present embodiment provides a kind of preparation method of cement grinding aid, comprises the following steps:

[0041] (1) Preparation of polydopamine / catechol modified chitosan powder, the method is as follows:

[0042] S1. Preparation of catechol-modified chitosan: 100 parts by weight of chitosan is dissolved in 200 parts by weight of 10wt% acetic acid solution, then the KOH solution of 2mol / L is added to adjust the pH value to 6, and 100 parts by weight of Add 30 parts by weight of 3,4-dihydroxyphenylacetic acid aqueous solution into the above solution, dropwise add 20 parts by weight of 60 wt% ethanol aqueous solution containing 1 part by weight of EDC and 1 part by weight of NHS, stir for 12 hours, filter, Washing to obtain catechol-modified chitosan;

[0043] S2. Preparation of polydopamine / catechol-modified chitosan: add 100 parts by weight of catechol-modified chitosan prepared in step S1 to 200 parts by weight of water, 1000W ultrasonic dispersion for 30...

Embodiment 3

[0047] The present embodiment provides a kind of preparation method of cement grinding aid, comprises the following steps:

[0048] (1) Preparation of polydopamine / catechol modified chitosan powder, the method is as follows:

[0049] S1. Preparation of catechol-modified chitosan: Dissolve 100 parts by weight of chitosan in 200 parts by weight of 10wt% acetic acid solution, then add 1.5mol / L of NaOH solution, adjust the pH value to 5.5, and dissolve 100 parts by weight of Add 22 parts by weight of an aqueous solution of 3,4-dihydroxyphenylacetic acid into the above solution, dropwise add 20 parts by weight of 45 wt% ethanol aqueous solution containing 0.7 parts by weight of EDC and 0.7 parts by weight of NHS, stir for 10 hours, and filter , washed with water to obtain catechol-modified chitosan;

[0050] S2. Preparation of polydopamine / catechol-modified chitosan: add 100 parts by weight of catechol-modified chitosan prepared in step S1 to 200 parts by weight of water, 1000W ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com