Method for decorating ceramic by using crystalline silicon

A technology of crystalline silicon and ceramics, applied in the field of preparation of various ceramic materials, can solve the problems of inability to meet product requirements, unsuitable rapid sintering, harsh crystallization temperature, etc., to achieve outstanding flash effect, and the sintering cycle can be long or short. , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

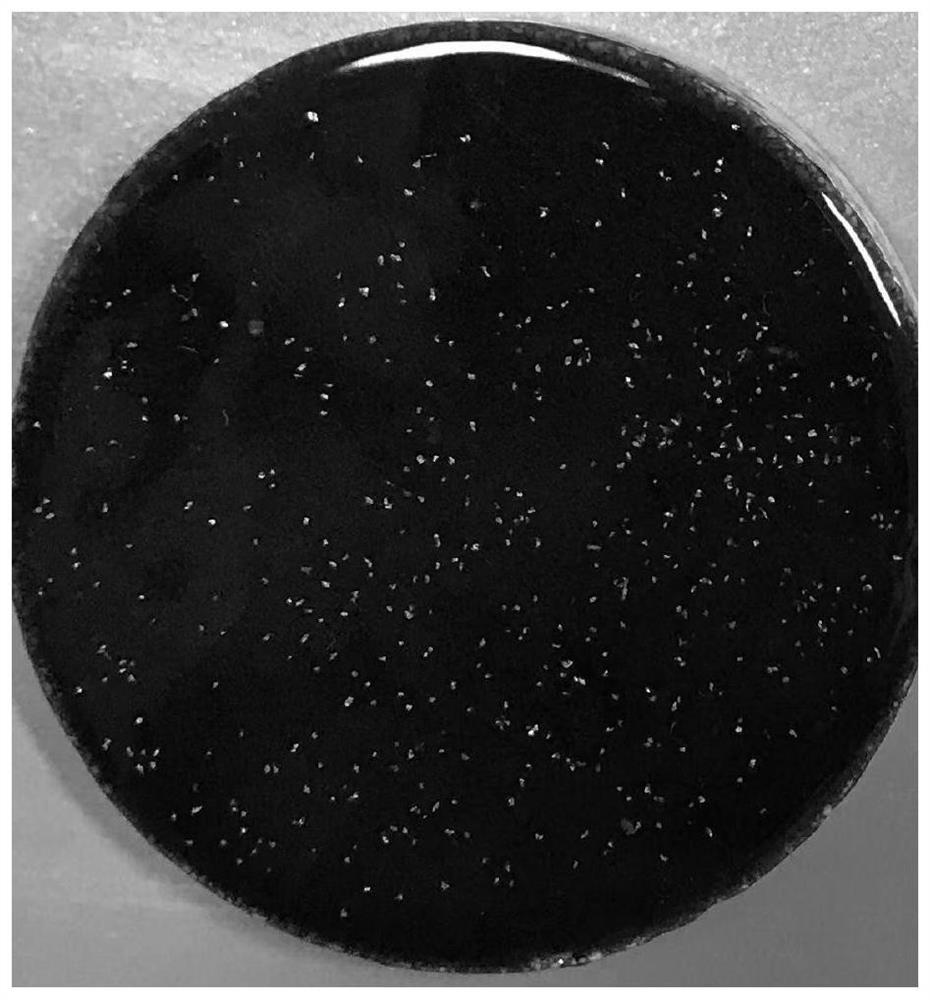

Image

Examples

Embodiment

[0037] A method of using crystalline silicon to decorate ceramics, comprising the steps of:

[0038] (1) Take the crystalline silicon or the soaking solution and soak the dried crystalline silicon.

[0039] Further, the soaking solution is any one of specific salts or alkalis.

[0040] Further, the crystalline silicon is any one of single crystal silicon, polycrystalline silicon, metallic silicon and elemental silicon.

[0041] Further, the particle size of the crystalline silicon is 10 mesh-200 mesh (2.00mm-0.080mm).

[0042] It should be noted that the crystalline silicon used in the present invention can be industrial products, waste scraps, or waste silicon panels for solar energy, etc. after processing. Crystalline silicon belongs to atomic crystals and is gray with metallic luster. Black solid, high hardness, brittle, chemically inactive at room temperature, a non-metallic element whose activity increases when the temperature rises.

[0043] (2) Using the crystalline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap