Thermally-stable ABS (Acrylonitrile Butadiene Styrene) resin composition

A technology of ABS resin and composition, applied in the field of thermally stable ABS resin composition, which can solve the problems of economic constraints, insufficient dispersion of resin matrix, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

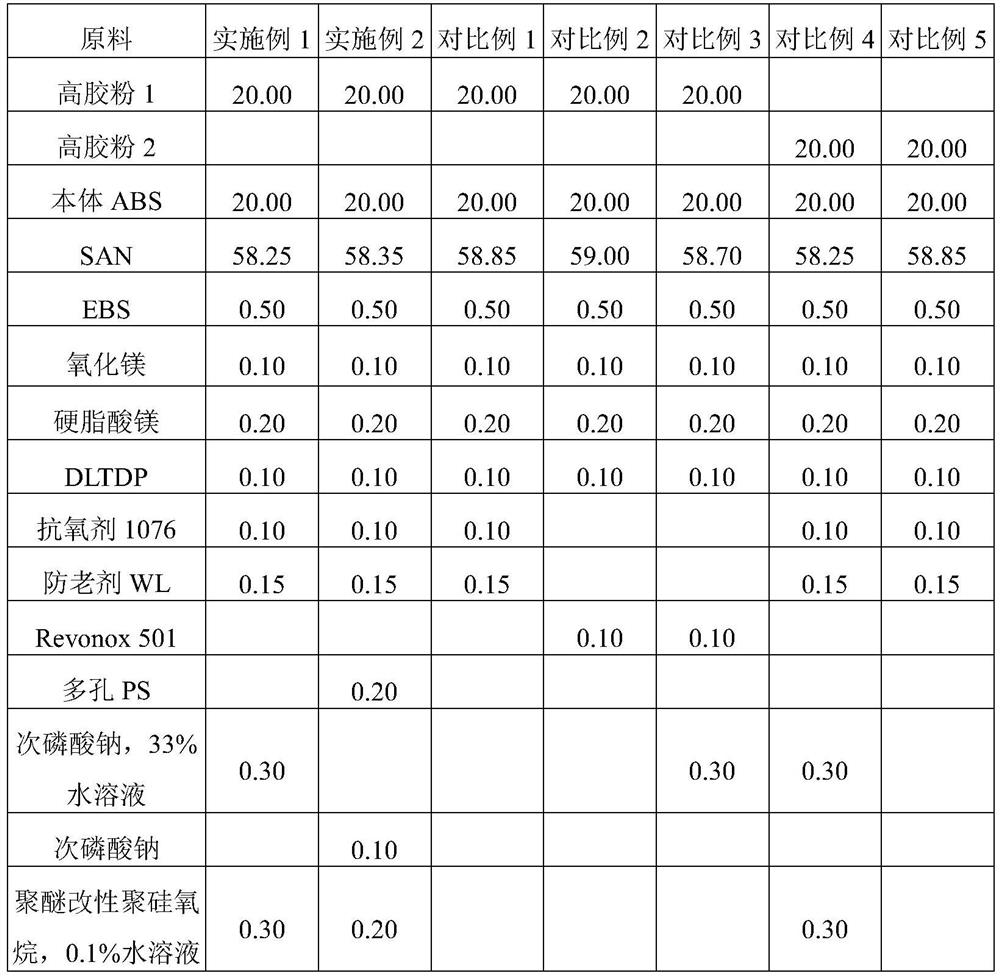

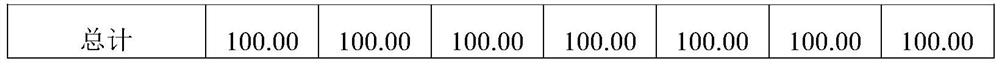

[0071] The present embodiment prepares a kind of ABS resin composition according to the formula shown in table 2 through the following steps:

[0072] (1) the mass fraction of preparation sodium hypophosphite is 33% sodium hypophosphite aqueous solution, the mass fraction of preparation polyether modified polysiloxane is the polyether modified polysiloxane aqueous solution of 0.1%;

[0073] (2) premixing all solid raw materials to obtain a premix;

[0074] (3) Pour pre-prepared sodium hypophosphite aqueous solution and polyether modified polysiloxane aqueous solution into the premix, and mix;

[0075] (4) Melt blending and granulation: According to the temperature conditions shown in Table 1, a twin-screw extruder was used to blend and granulate the material obtained in step (3) to obtain an ABS resin composition.

Embodiment 2

[0077] The present embodiment prepares a kind of ABS resin composition according to the formula shown in table 2 through the following steps:

[0078] (1) the mass fraction of preparation polyether-modified polysiloxane is the polyether-modified polysiloxane aqueous solution of 0.1%;

[0079] (2) Add porous PS, sodium hypophosphite, and polyether-modified polysiloxane aqueous solution prepared in advance to the container, stir and let stand, and wait for the porous PS to absorb the solution;

[0080] (3) mixing the material obtained in step (2) with resin and other additives;

[0081] (4) Melt blending and granulation: According to the temperature conditions shown in Table 1, a twin-screw extruder was used to blend and granulate the material obtained in step (3) to obtain an ABS resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com