Molybdenum disulfide nano lubricating oil capable of stably existing and preparation method of molybdenum disulfide nano lubricating oil

A molybdenum disulfide, lubricating oil technology, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of poor suspension stability, aggregation, complex preparation process, etc., and achieve the effects of low cost, simple preparation process and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

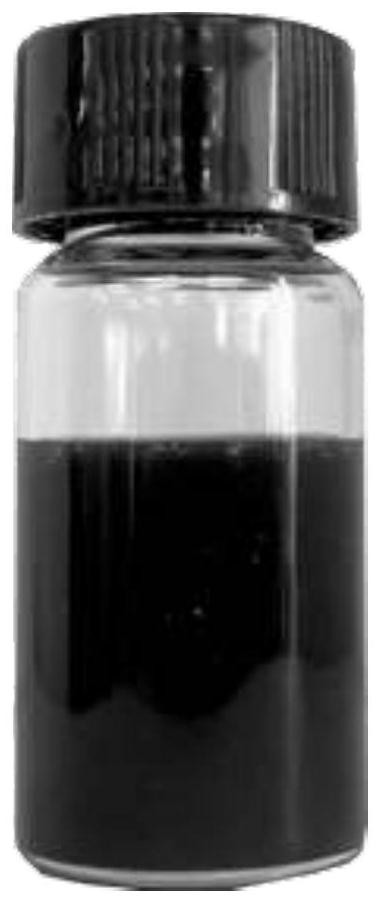

Embodiment 1

[0038] In this embodiment, the stable molybdenum disulfide nano lubricating oil is composed of molybdenum disulfide powder, dispersant mixed liquid and base oil; in the molybdenum disulfide nano lubricating oil, the mass fraction of the dispersant mixed liquid is 12wt%. The massfraction of molybdenum disulfide powder is 0.5wt%; Described dispersant mixed liquid is made of oleic acid (Oleic acid, chemical formula C 18 h 34 o 2 ), oleylamine (Oleylamine, chemical formula C 18 h 37 N) and n-dodecanethiol (1-Dodecanethiol, chemical formula C 12 h 26 S) composition, the mass ratio of oleic acid, oleylamine and n-dodecanethiol is 1:2:1; the particle size of molybdenum disulfide powder is 50-200nm; the base oil is 32# base oil, which is industrial grade white oil.

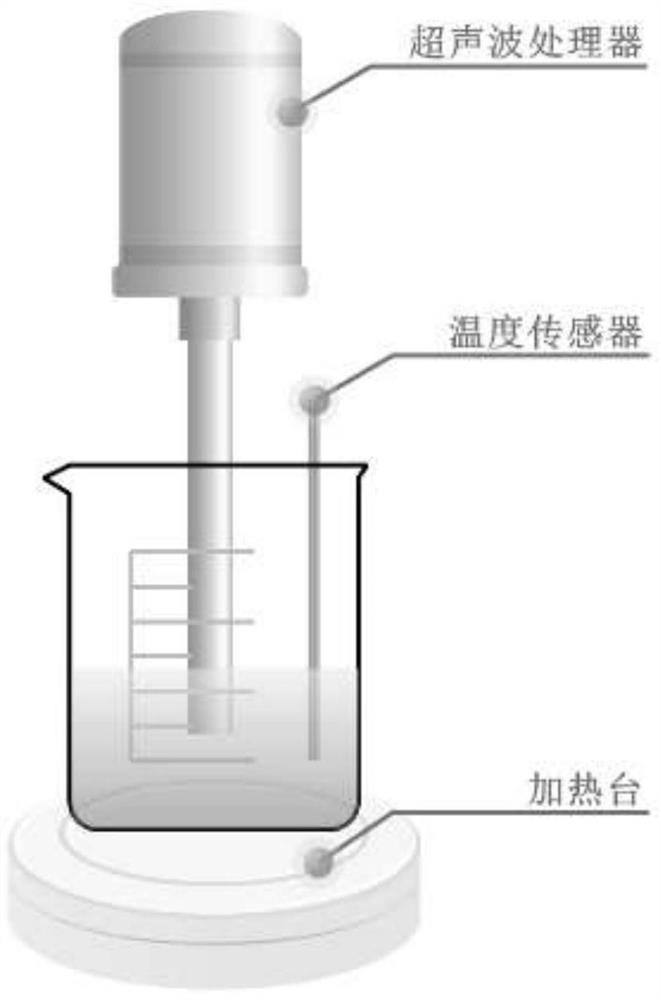

[0039] The preparation method of the above-mentioned molybdenum disulfide nano lubricating oil that can exist stably comprises the steps:

[0040] Step A: Add 9g of oleic acid, 18g of oleylamine and 9g of n-dodecan...

Embodiment 2

[0049] In this embodiment, the stable molybdenum disulfide nano lubricating oil is composed of molybdenum disulfide powder, dispersant mixed liquid and base oil; in the molybdenum disulfide nano lubricating oil, the mass fraction of the dispersant mixed liquid is 12wt%. The massfraction of molybdenum disulfide powder is 0.3wt%; Described dispersant mixed liquid is made of oleic acid, (Oleic acid, chemical formula C 18 h 34 o 2 ), oleylamine (Oleylamine, chemical formula C 18 h 37 N) and n-dodecanethiol (1-Dodecanethiol, chemical formula C 12 h 26 S) composition, the mass ratio of oleic acid, oleylamine and n-dodecanethiol is 1:2:1; the particle size of molybdenum disulfide powder is 50-200nm; the base oil is 150# base oil, which is also an industrial grade white oil.

[0050] The preparation method of the above-mentioned molybdenum disulfide nano lubricating oil that can exist stably comprises the steps:

[0051] Step A: Add 9g of oleic acid, 18g of oleylamine and 9g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com