Full-degradable plant fiber coating paper

A plant fiber layer and plant fiber technology, applied in the field of fully degradable plant fiber coated paper, can solve the problems of complicated recycling and degradation, increased paper cost, environmental damage, etc., to ensure environmental safety, improve processing efficiency, and accelerate degradation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

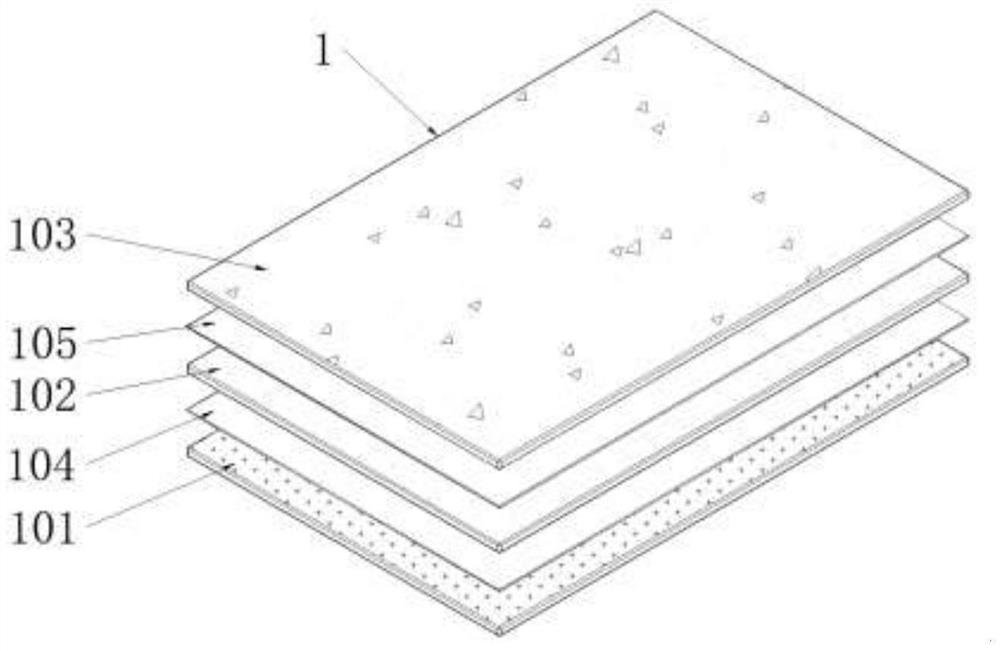

[0046] see Figure 1-2 , a fully degradable plant fiber coated paper, including a paper body 1, the paper body 1 includes a plant fiber layer 101, a plant fiber layer 2 102 and a plant fiber layer 3 103 stacked up and down, a plant fiber layer 101 and plant fibers An acidic layer 104 is set between the second layer 102, and an alkaline layer 105 is set between the second plant fiber layer 102 and the third plant fiber layer 103. In this scheme, acid powder and alkaline powder are respectively attached to the first plant fiber layer 101 and An acidic layer 104 and an alkaline layer 105 are formed between the second plant fiber layer 102 and the second plant fiber layer 102 and the third plant fiber layer 103 .

[0047] When the device needs to be degraded, it is only necessary to soak the paper body 1 in a humid environment and be infiltrated by moist gas, so that the acidic powder and alkaline powder inside the acidic layer 104 and alkaline layer 105 can fully penetrate into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com