Outer surface anti-corrosion composite metal pipe based on cathode protection and manufacturing method of outer surface anti-corrosion composite metal pipe

A composite metal pipe and cathodic protection technology, applied in pipeline protection, pipeline anti-corrosion/rust protection, pipes, etc., can solve the problems of accelerated substrate pipe corrosion, increased production and operation costs of pipelines, and short timeliness, so as to improve service life and safety, and the effect of improving the overall anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

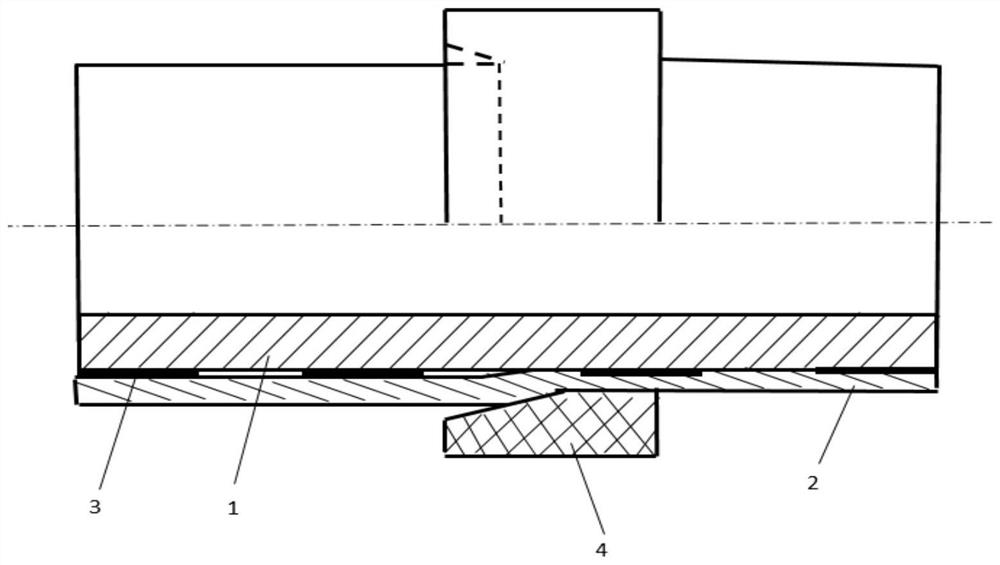

[0041] Such as figure 1 As shown, an anti-corrosion composite metal pipe on the outer surface based on cathodic protection includes an inner basic metal pipe 1 and a surface corrosion-resistant metal pipe 2; , filled with metal glue 3 for sealing and bonding; the surface corrosion-resistant metal pipe 2 is physically composited with the inner basic metal pipe 1 through hot extrusion deformation; the thickness of the inner basic metal pipe 1 is 8mm, and the surface layer The thickness of the corrosion-resistant metal pipe 2 is 2.5mm.

[0042] In this embodiment, the inner basic metal pipe 1 is a seamless rolled pipe made of low-alloy carbon steel with a smooth outer surface, and the yield strength of the material is 551 MPa. The out-of-roundness of the outer circumference of the inner basic metal pipe 1 is less than 2.5%. The material of the surface corrosion-resistant metal pipe 2 is 2000 series aluminum alloy, and the yield strength of the material is 338MPa.

[0043] Befo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com