Preparation method of X-ray detector

A detector and X-ray technology, applied in the field of preparation of X-ray detectors, can solve problems such as poor performance of X-ray detectors, achieve the effects of improving carrier collection efficiency, improving electrical performance, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of an X-ray detector, comprising the following steps:

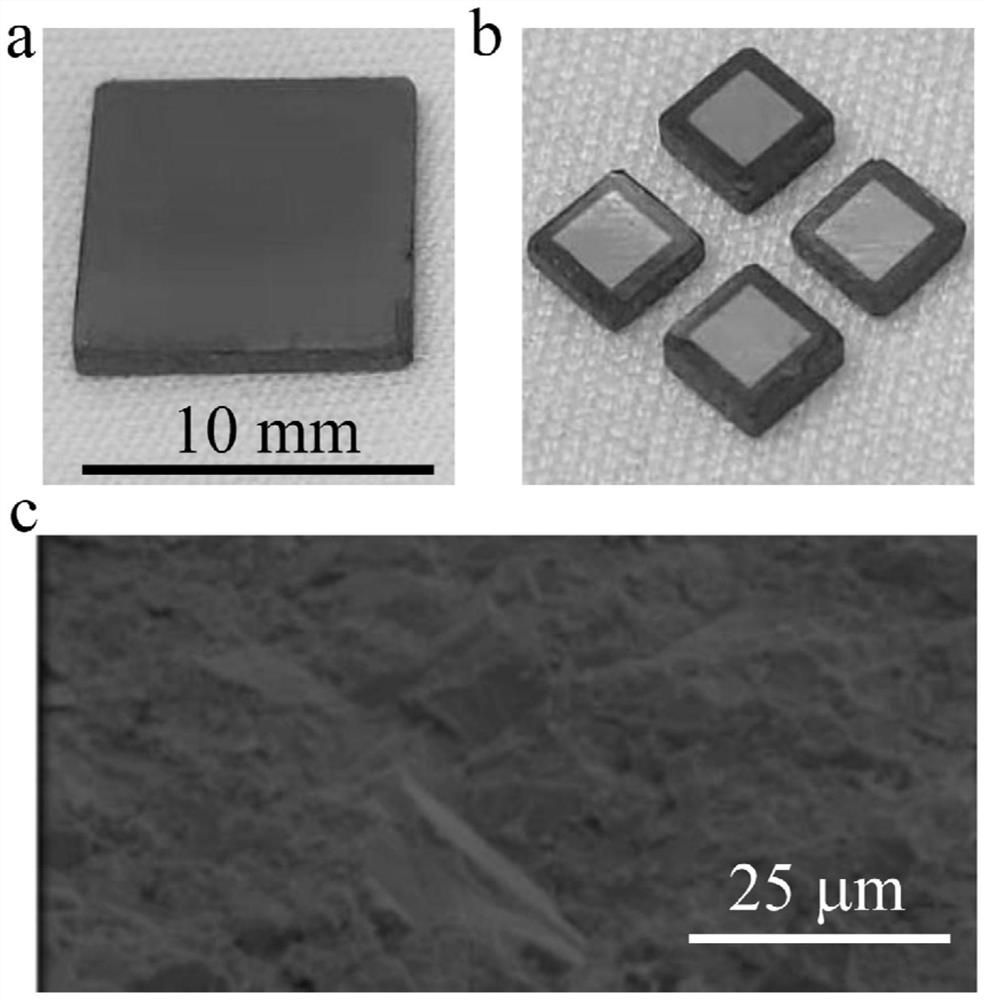

[0022] S1. Use a ball mill to grind the perovskite and MXene bulk materials, and mix the ground perovskite and MXene powder materials evenly;

[0023] S2. Put the perovskite and MXene mixed powder material into a stainless steel mold, and use a manual tablet press to continuously apply a pressure of 20Mpa for 2 minutes to press the perovskite and MXene mixed powder material into a block with regular shape and dense surface;

[0024] S3, further using a cold isostatic press to apply a pressure of 200Mpa to the block prepared in step S2 for 15 minutes, and finally obtain a perovskite / MXene composite absorbent material with a dense cross-section;

[0025] S4. Finally, thermal evaporation equipment is used to evaporate electrodes on both sides of the perovskite / MXene composite absorption material obtained in step S3 to form an X-ray detector with a metal / semiconductor / metal structure.

[0026] In ...

Embodiment 1

[0028] A preparation method of an X-ray detector, comprising the following steps:

[0029] S1. Use a ball mill to grind the perovskite and MXene bulk materials, and mix the ground perovskite and MXene powder materials evenly;

[0030] S2. Put the perovskite and MXene mixed powder material into a stainless steel mold, and use a manual tablet press to continuously apply a pressure of 20Mpa for 2 minutes to press the perovskite and MXene mixed powder material into a block with regular shape and dense surface;

[0031] S3, further using a cold isostatic press to apply a pressure of 200Mpa to the block prepared in step S2 for 15 minutes, and finally obtain a perovskite / MXene composite absorbent material with a dense cross-section;

[0032] S4. Finally, thermal evaporation equipment is used to evaporate electrodes on both sides of the perovskite / MXene composite absorption material obtained in step S3 to form an X-ray detector with a metal / semiconductor / metal structure.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap