Mixing device for die steel casting and capable of reducing segregation degree

A stirring device and die steel technology, which is applied in the field of die steel casting equipment, can solve the problems of reducing the performance of H13 hot work die steel, reducing the service life of the die, and uneven core structure, so as to save energy consumption, increase fluidity, even size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

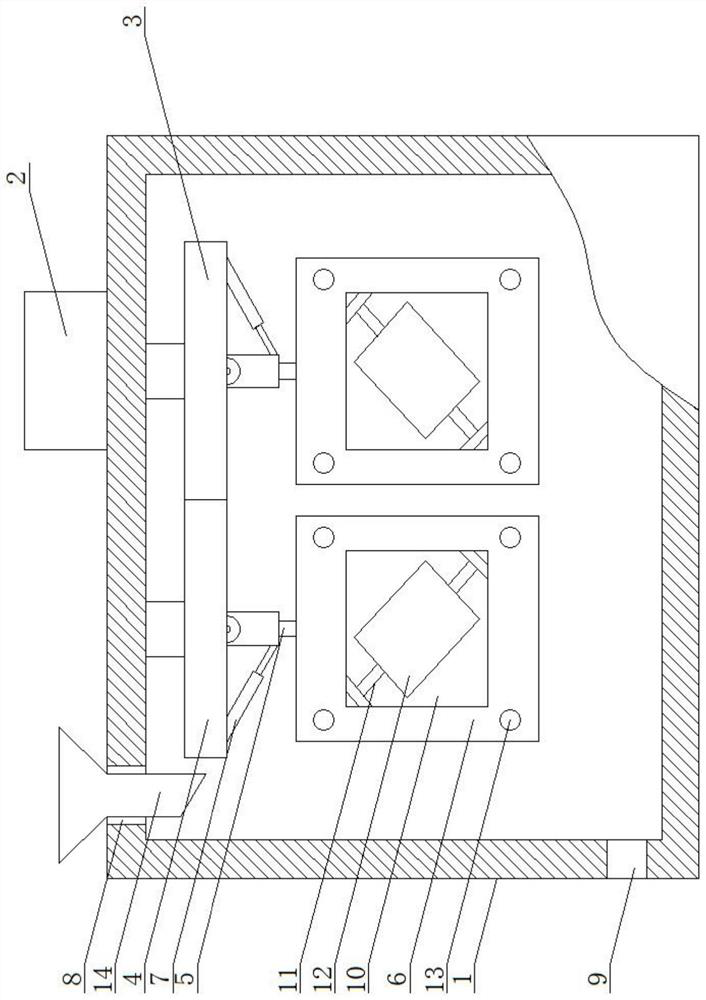

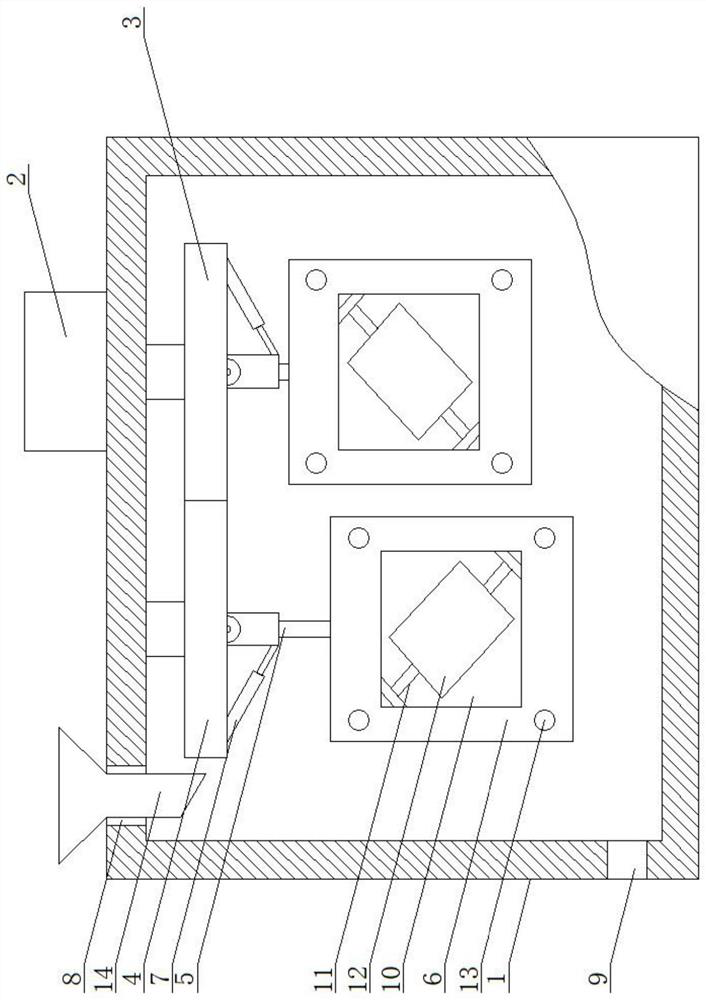

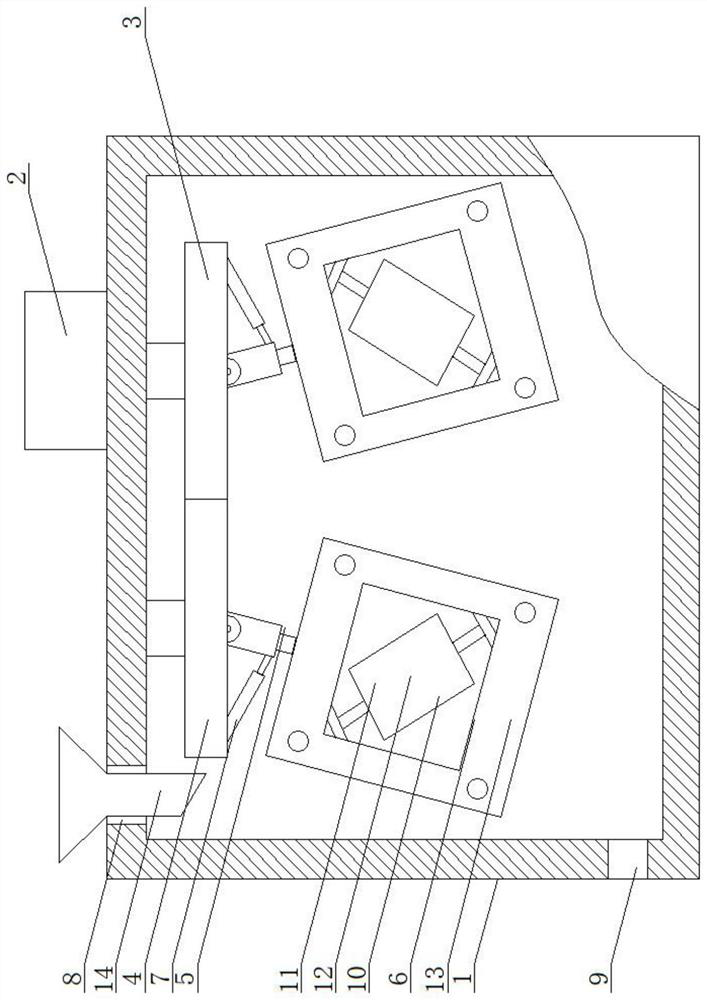

[0024] When using this device, first put molten steel into the box 1 through the feed port 8, and then make the motor 2 work (forward or reverse), and the motor 2 is driven by the cooperation of the first gear 3 and the second gear 4 The first telescopic rod 5 rotates, and the rotation of the first telescopic rod 5 drives the stirring plate 6 to rotate, and the stirring plate 6 stirs the molten steel, and simultaneously makes two first telescopic rods work in the direction (wherein one of the first telescopic rods 5 stretches, and the other A first telescopic rod 5 shrinks) as figure 2 As shown, and then make two stirring plates 6 produce height difference, and then when stirring molten steel, make molten steel produce height difference, increased the fluidity of molten steel; Make the second telescopic rod 7 work simultaneously, the second telescopic rod 7. The work drives the first telescopic rod 5 to overturn around the hinge point, such as image 3 As shown, the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com