Method for repairing 7-series aluminum alloy through small-spot laser additive under atmosphere protection condition

A repair method and laser additive technology, applied in additive processing, process efficiency improvement, additive manufacturing, etc., to achieve the effects of improving laser energy absorption, strengthening metallurgical bonding, and reducing reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

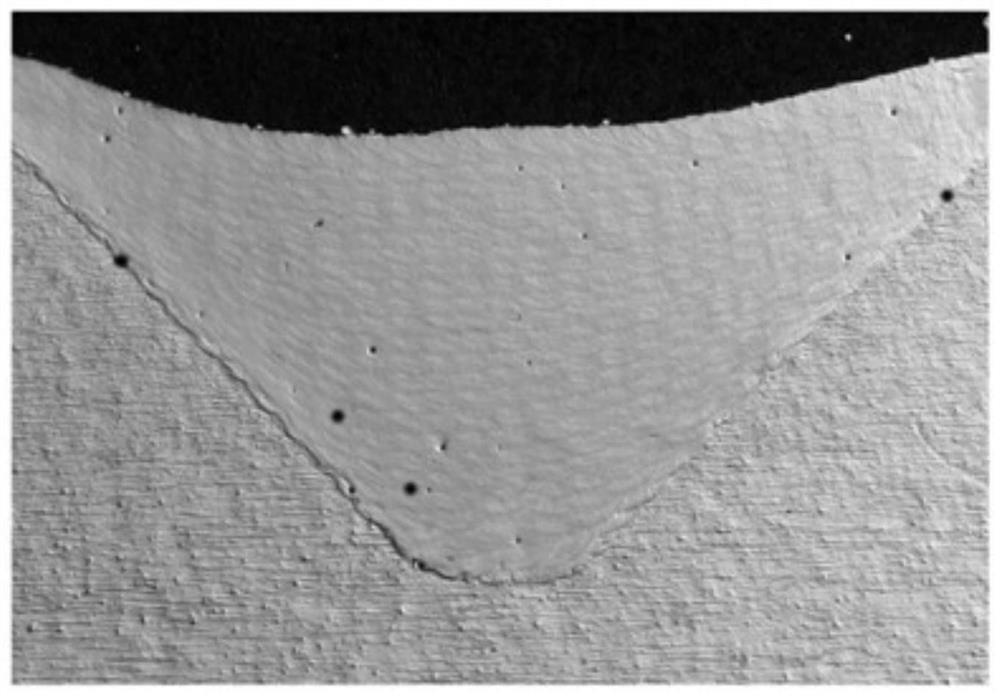

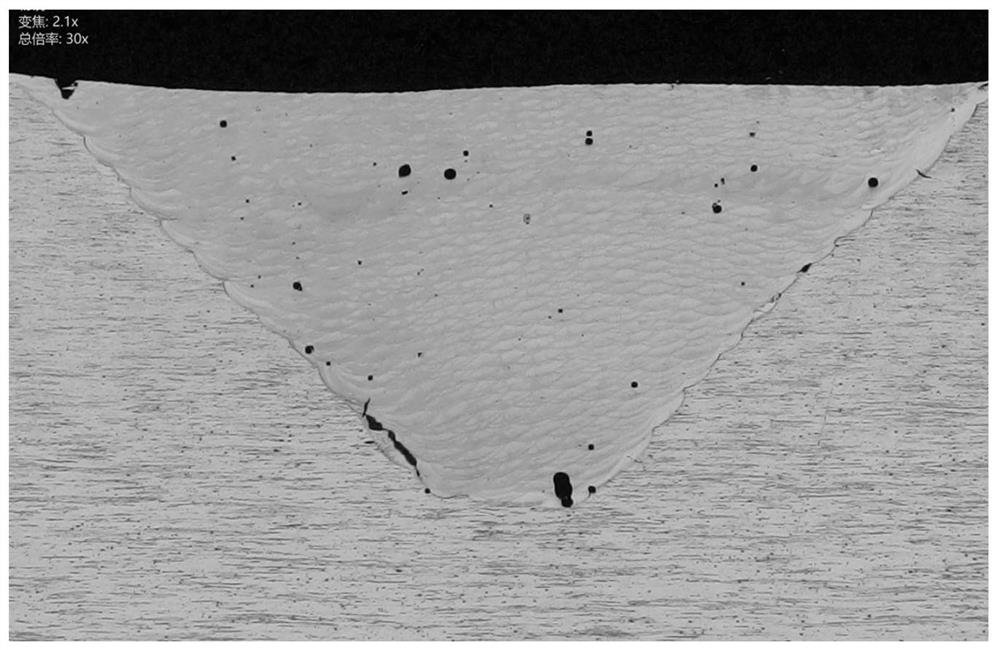

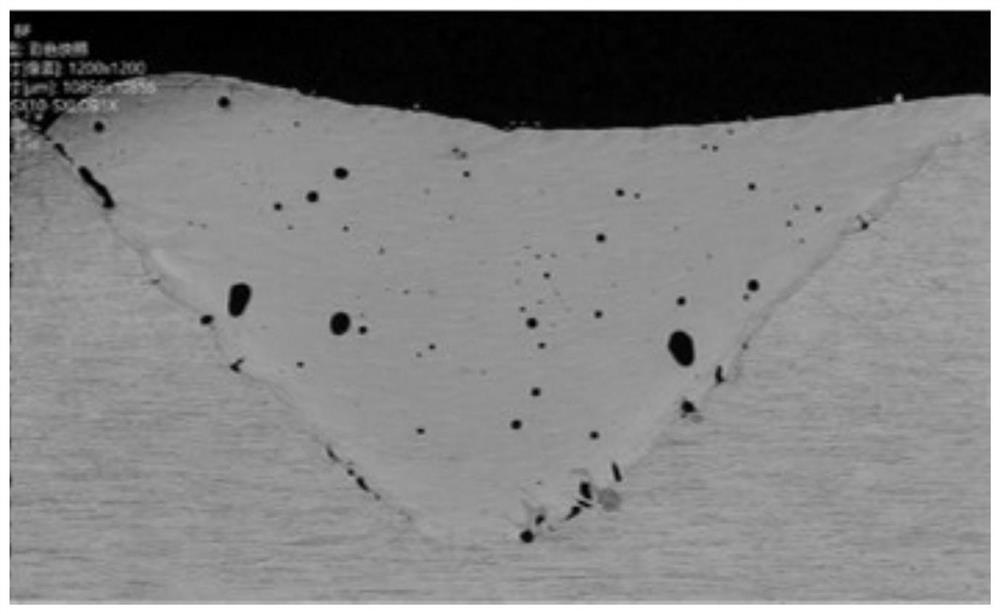

[0045] This embodiment provides a method for repairing a 7-series high-strength aluminum alloy plate by using Al-Mg-Sc-Zr high-strength aluminum alloy powder as a repair material and using a laser additive repair technology. The repair process uses small light spots and atmosphere protection, and repairs the aluminum alloy prefabricated grooves.

[0046] Specific steps are as follows:

[0047] (1) The 7B05 aluminum alloy plate was selected as the base material, and the specific composition of the base material is shown in Table 1. The V-shaped groove is processed on the substrate by wire cutting, machining, etc. The groove angle is 90°~120°, and the depth is 1~8mm (this depth can cover most of the existing aluminum alloy damage depth).

[0048] The cladding material is aluminum-magnesium-scandium-zirconium-aluminum alloy spherical powder with a particle diameter of 50-120 μm;

[0049] The composition of aluminum-magnesium-scandium-zirconium-aluminum alloy is shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com