Ferromagnetic dish-washing machine meal box automatic transverse stacking machine and transverse stacking method

A ferromagnetic, dishwasher technology, applied in conveyors, object stacking, conveyor objects and other directions, can solve the problems of subsequent processing difficulties, limited number of stacking, deformation of lunch box stamping parts, etc., to improve processing efficiency and yield, ensure shape and dimensional stability, and enhance the effect of production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

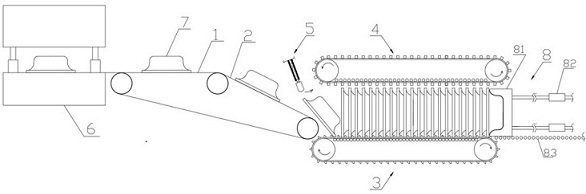

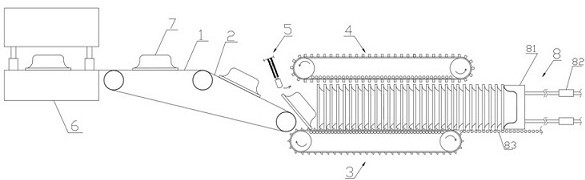

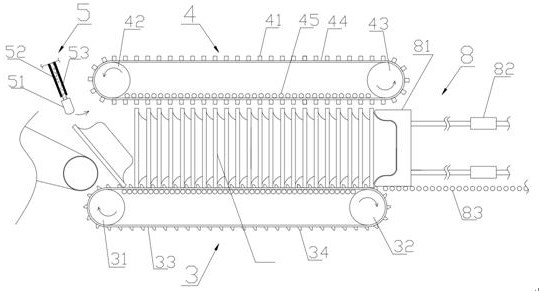

[0040] see Figures 1 to 4 , ferromagnetic dishwasher lunch box automatic horizontal palletizer, including sequential connection:

[0041] The horizontal transmission mechanism 1 receives the stamped part 7 of the lunch box stamped by the automatic continuous stamping machine 6;

[0042] Tilt the transmission mechanism 2, so that the lunch box stamping part 7 is transferred to an inclined posture for transmission;

[0043] The bottom attitude adjustment mechanism 3 limits the position of the bottom of the stamping part 7 of the lunch box, and drives the stamping part 7 of the lunch box to advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com