Four-element synergistic efficient flame-retardant polypropylene material and preparation thereof

A flame-retardant polypropylene and four-element technology, which is applied in the field of four-element synergistic high-efficiency flame-retardant polypropylene material and its preparation, can solve the problems that are rarely reported in the literature, and achieve less usage, low smoke generation, and flame-retardant effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

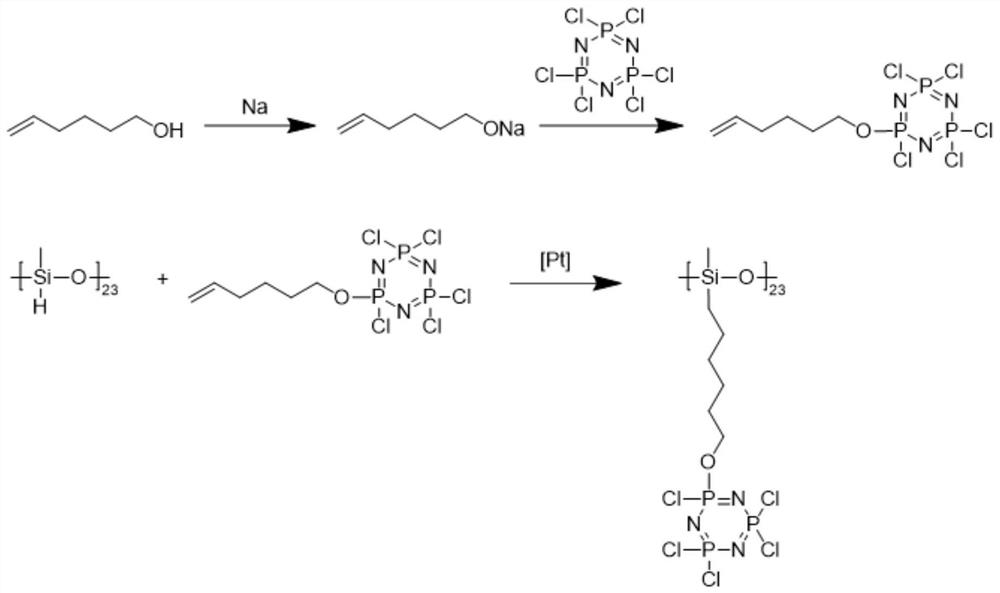

[0019] refer to figure 1 As shown, the embodiment of the present invention provides a method for preparing a four-element synergistic high-efficiency flame-retardant polypropylene material, comprising the following steps:

[0020] S1, dissolve polymethylhydrogensiloxane in solvent, add hexenyloxy pentachlorotripolyphosphazene, and add catalyst, stir and react for 10 to 40 hours, remove solvent and dry to obtain polymer flame retardant ;

[0021] S2. Weigh a number of polymer flame retardants and polypropylene material particles for blending, pour the uniformly mixed samples into an internal mixer, and melt blend to obtain a four-element synergistic high-efficiency flame-retardant polypropylene material.

[0022] In step S1, in the polymethylhydrogensiloxane [-SiH-O-]n, the value of n is 20-30, that is, the number of repeating units is 20-30. If the number of repeating units is too large, it is easy to cause the molecular weight of the subsequent polymer flame retardant to be...

Embodiment 1

[0038]Add 10.0g of 5-hexen-1-ol into 50ml of diethyl ether and stir, then add sliced metal sodium 2.3g at room temperature and react for 24h under the protection of nitrogen, filter out insoluble matter, slowly drop the filtrate into 34.5 hexachlorotrimeric phosphazene g in 150 ml of ether solution, the reaction was continued for 24 h under the protection of nitrogen, and the solvent was spin-dried to obtain hexenyloxypentachlorotrimeric phosphazene, which was then vacuum-dried to constant weight to obtain a white solid with a yield of 92%. Dissolve 1.4g of polymethylhydrogensiloxane in 100ml of ether, add 9.4g of hexenyloxypentachlorotripolyphosphazene, drop in a small amount of Karl Fischer's catalyst, stir for 24 hours, spin dry the solvent, and dry to constant weight , yield 98%. 1 wt% polymer flame retardant and 99 wt% polypropylene material particles were weighed and blended to obtain a series of blended samples. Pour the homogeneously mixed sample into the internal m...

Embodiment 2

[0042] It is basically the same as Example 1, except that the flame retardant polymer material formula is: 2% polymer flame retardant, 98% polypropylene.

[0043] test:

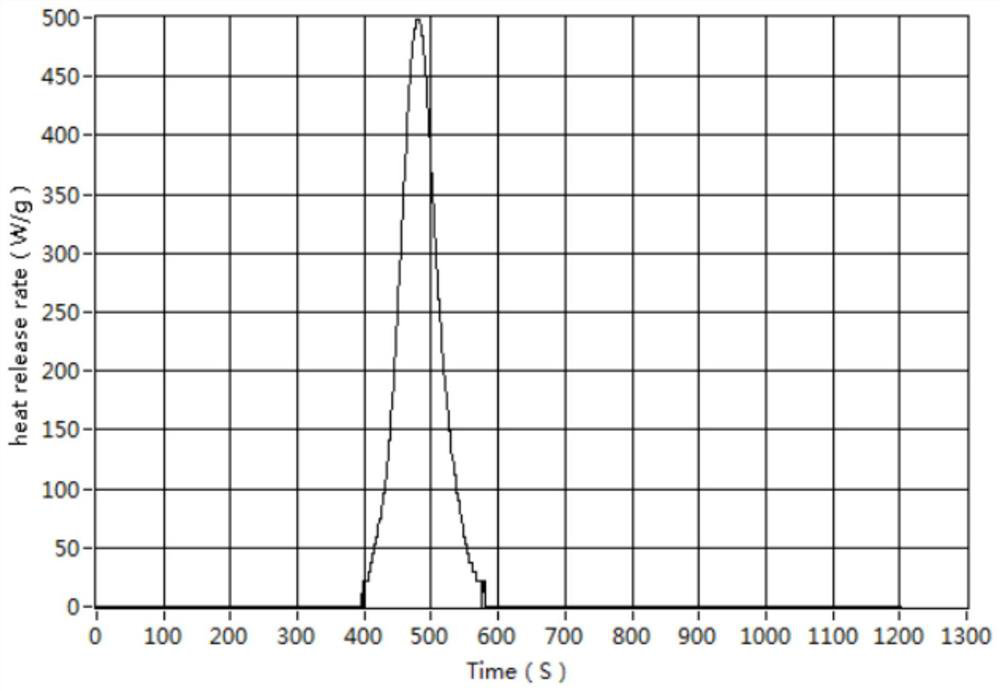

[0044] Please also see image 3 , image 3 Be the heat release rate spectrogram of embodiment 2. Further, the limiting oxygen index of the material in Example 2 is 28.9%, the UL-94 vertical combustion test reaches the V-1 level, the tensile strength is 27.11MPa, the impact strength is 3.3KJ / m2, and the maximum heat release rate is 498.80W / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com