An aircraft electrostatic discharger radio frequency discharge noise test device and method

A technology of radio frequency discharge and experimental testing, which is applied in the direction of testing electrical devices in transportation, measuring devices, testing dielectric strength, etc., can solve the problems of staff injury, measurement error, poor safety, etc. Damage, easy to install and remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

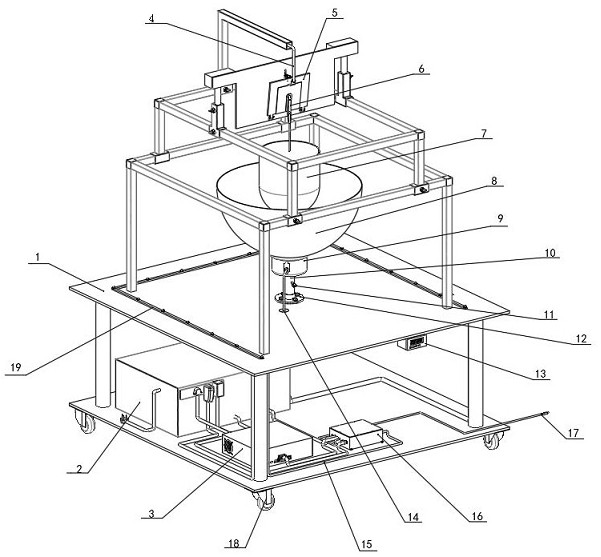

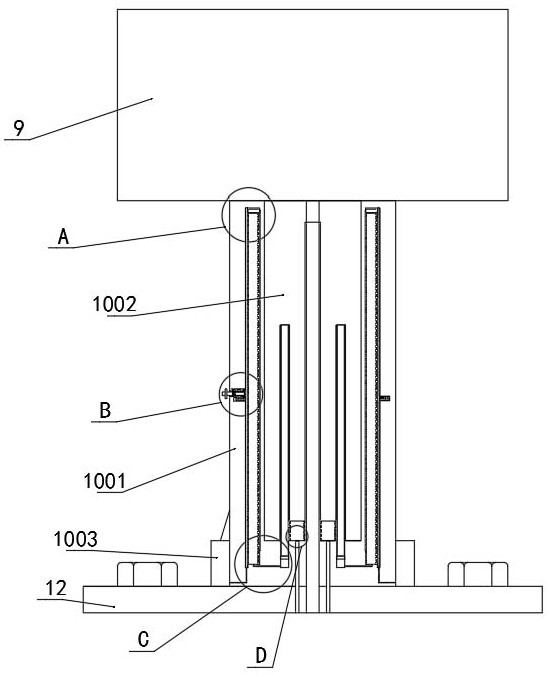

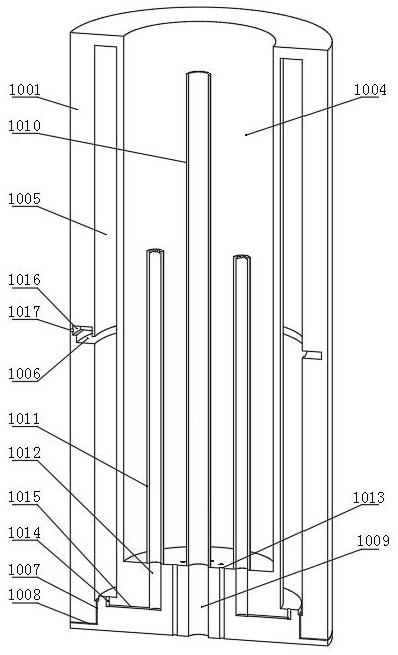

[0038] like figure 1 As shown, an aircraft electrostatic discharger radio frequency discharge noise test device includes a bracket 1, a DC program-controlled high-voltage power supply 2 arranged on the bracket 1, a structural capacitor 3, a high-voltage cable 4, a fixed sample base plate 5, a direct-reading microcomputer Safety meter 13, equivalent load 14, coaxial cable 15, RF noise true effective measurement controller 16, optical fiber 17, grounding bus bar 19 and base 12, telescopic mechanism 10 connected to the base 12, set in the telescopic mechanism 10 The adjusting mechanism 11, the bracket 9 connected to the top of the telescopic mechanism 10, the noise receiving electrode 8 and the high voltage electrode 7 connected to the bracket 9, the sample electrode 6 connected to the fixed sample base plate 5 and the bracket 1 Several universal wheels 18 at the bottom, the output end of the DC program-controlled high-voltage power supply 2 are respectively connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com