Metacresol deep desulfurization system and process

A deep desulfurization and m-cresol technology, applied in the field of chemical technology, can solve the problems of unsatisfactory desulfurization effect, failure to meet the requirements of environmental protection, and difficult separation of sulfide, and achieve simple structure, convenient operation and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

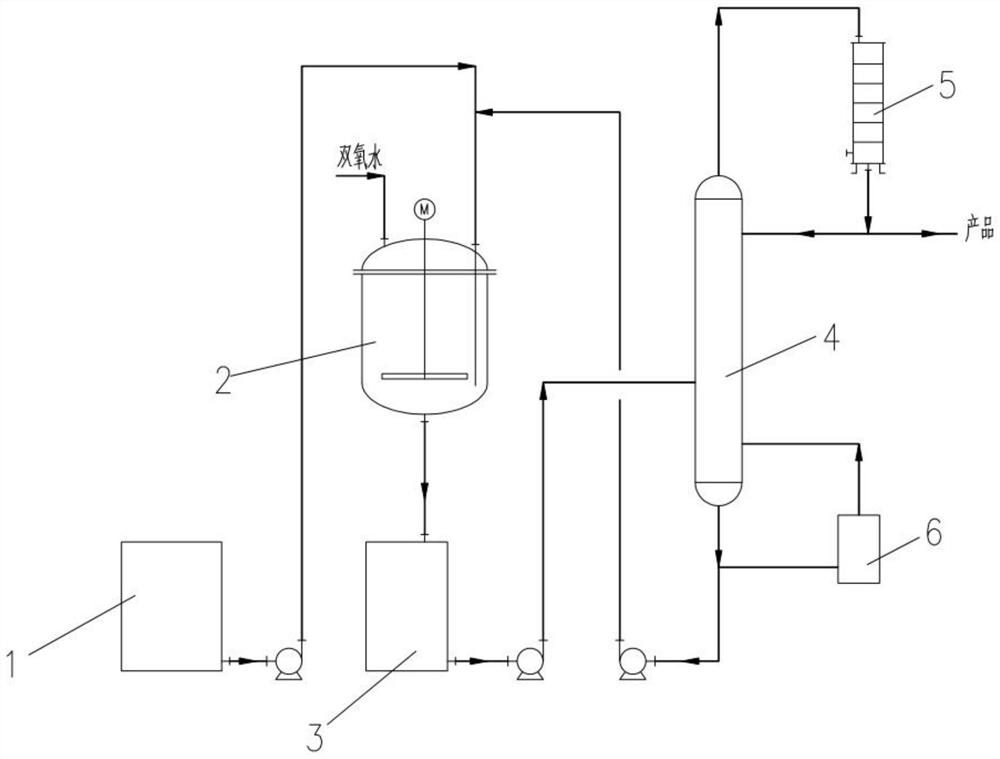

[0030] The system involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0031] The m-cresol deep desulfurization system used in the present invention includes a raw material tank 1, an oxidation unit and a rectification unit. The oxidation unit includes an oxidation still 2, and the inlet of the oxidation still 2 is connected to the outlet of the raw material tank 1. The rectification unit Including rectifying tower 4 and condenser 5, the outlet of oxidation still 2 is connected with rectifying tower 4, the outlet of rectifying tower 4 is connected with the inlet of condenser 5, and the outlet of condenser 5 is connected with rectifying tower 4 all the way, and outputs m Phenol products.

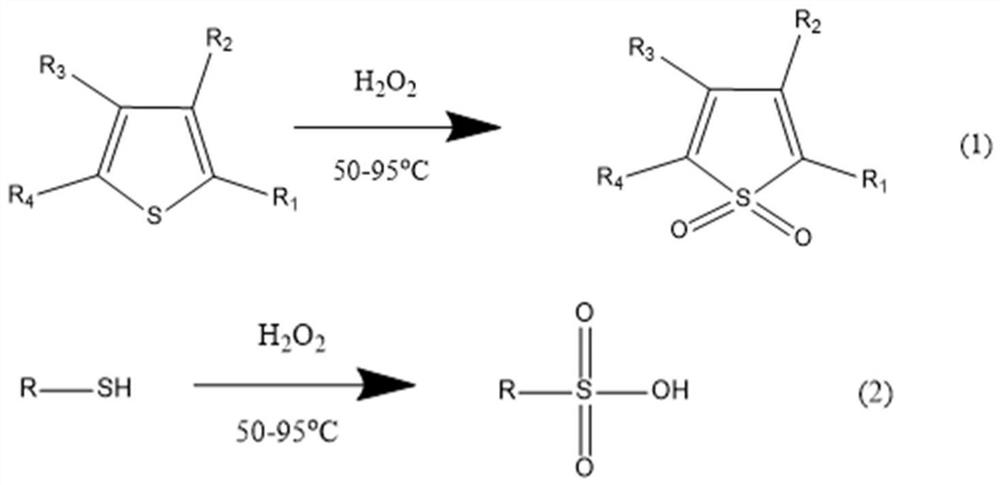

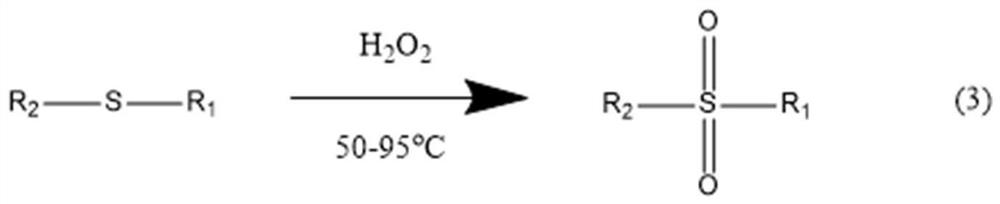

[0032] The raw material tank 1 is used to store the sulfur-containing m-cresol raw material obtained by the extraction method. The working principle of the oxidation unit is to oxidize sulfur-containing impurities such as thiophen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com