Polyol as well as preparation method and application thereof

A polyol and ring-opening reaction technology, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of cumbersome preparation process, complex content of side reaction products, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

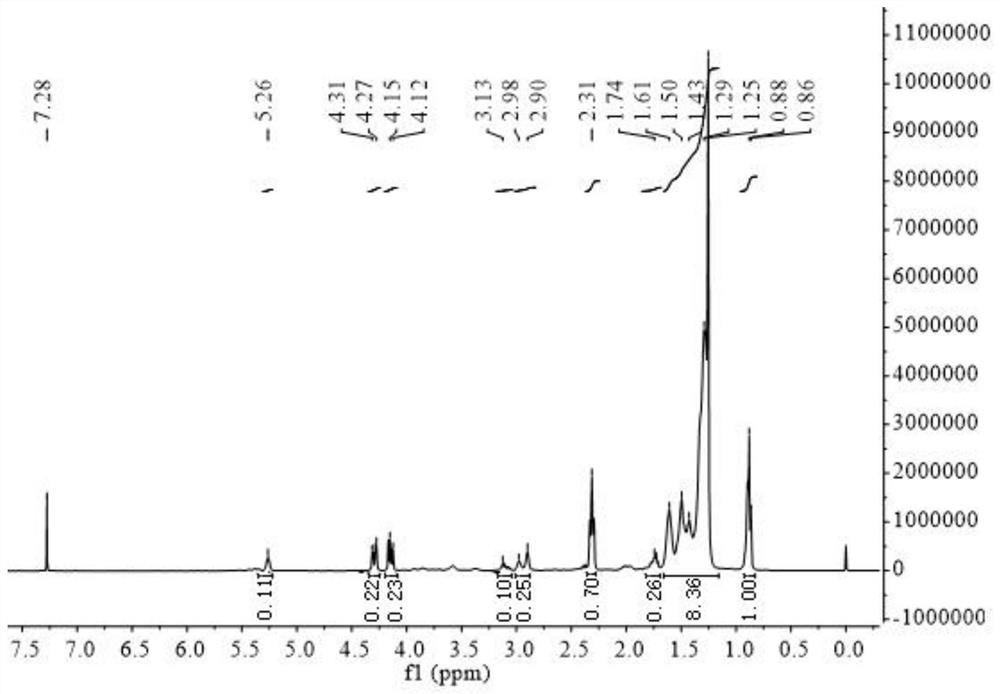

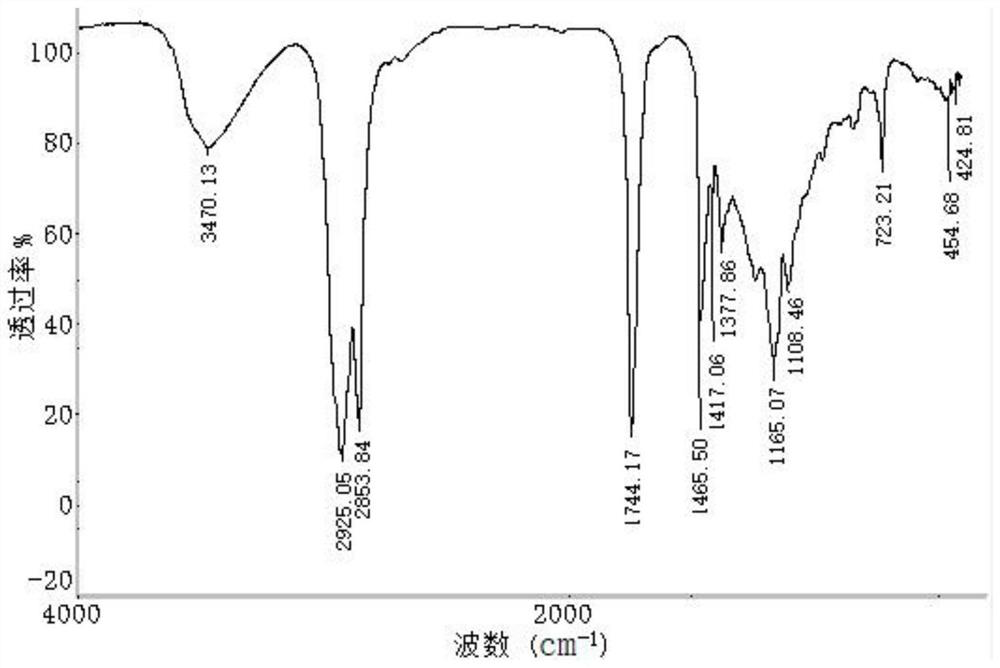

Image

Examples

preparation example Construction

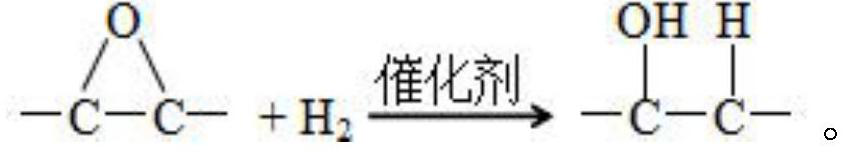

[0023] The invention provides a preparation method of polyol, comprising the following steps:

[0024] Under catalyst conditions, the epoxidized vegetable oil and hydrogen are subjected to a ring-opening reaction to obtain the polyol;

[0025] The catalyst comprises a nickel-based catalyst and an epoxidized vegetable oil on the surface of the nickel-based catalyst, and the epoxidized vegetable oil in the catalyst is the same as the epoxidized vegetable oil for ring-opening reaction;

[0026] The temperature of the ring-opening reaction is 140-180° C., and the reaction pressure is 0.4-0.8 Mpa.

[0027] In the present invention, unless otherwise specified, the components in the preparation method are all commercially available products well known to those skilled in the art.

[0028] In the present invention, under catalyst conditions, the epoxidized vegetable oil and hydrogen are subjected to a ring-opening reaction to obtain the polyol.

[0029] In the present invention, the...

Embodiment 1

[0049] The catalyst used includes a nickel-based catalyst and epoxidized soybean oil on the surface of the nickel-based catalyst, wherein the nickel-based catalyst is a spherical shape with a particle size of 4 mm, and includes a carrier natural diatomite and a nickel element supported on the carrier. The mass fraction of nickel element in the catalyst is 22%, and the mass ratio of the nickel-based catalyst to the epoxidized soybean oil on the surface of the nickel-based catalyst is 1:0.5;

[0050] Add 500g epoxidized soybean oil (epoxy value 6.20%) and 1g catalyst to the autoclave successively, and seal the autoclave; after leak detection to ensure that the autoclave is sealed, replace the gas in the autoclave three times with hydrogen, then Set the reaction temperature to 160 °C, feed hydrogen to 0.6 MPa under stirring conditions, and gradually start the reaction as the temperature rises. When the pressure drops to 0.4 MPa, replenish hydrogen to 0.6 MPa in time; when the pres...

Embodiment 2

[0056] The catalyst used includes a nickel-based catalyst and epoxy rapeseed oil on the surface of the nickel-based catalyst, wherein the nickel-based catalyst is an ellipsoid with a particle size of 4 mm, and includes a carrier clay and a nickel element supported on the carrier. The nickel-based catalyst The mass fraction of the nickel element in the medium is 20%, and the mass ratio of the nickel-based catalyst and the epoxy rapeseed oil on the surface of the nickel-based catalyst is 1:0.3;

[0057] Add 500g epoxy rapeseed oil (epoxy value 5.85%) and 1.5g catalyst to the autoclave successively, and seal the autoclave; after checking for leaks to ensure that the autoclave is sealed, replace the gas in the autoclave three times with hydrogen , and then set the reaction temperature to 140 °C, feed hydrogen to 0.6 MPa under stirring conditions, and gradually start the reaction as the temperature rises. When the pressure drops to 0.4 MPa, add hydrogen to 0.6 MPa in time; when the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com