Method and system for treating ammonia-containing tail gas and simultaneously reducing nitric oxide in coke oven flue gas

A technology of nitrogen oxides and purification system, which is applied in the heating of coke ovens, combustible gas heating coke ovens, coke ovens, etc., can solve the problems of direct discharge of ammonia-containing tail gas and excessive nitrogen oxide content in coke oven flue gas, and achieve Effects of reducing processing load, reducing cost, and avoiding direct discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

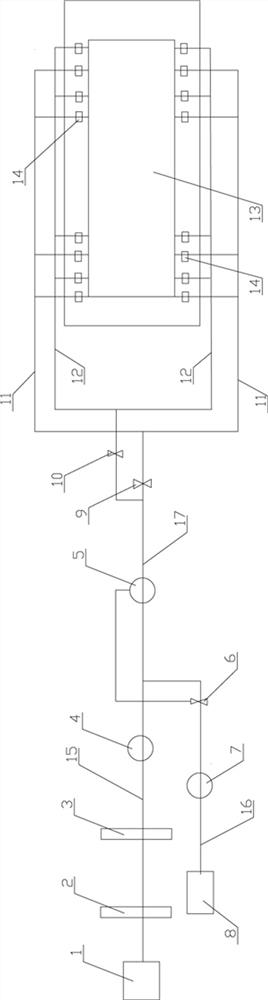

[0016] The method for treating ammonia-containing tail gas and simultaneously reducing nitrogen oxides in coke oven flue gas in this embodiment includes the following steps:

[0017] 1) The ammonia-containing tail gas generated from the storage tank of the gas purification system is collected and transported to the pickling tower for pickling through pipelines;

[0018] 2) The tail gas after pickling is sent to the alkaline washing tower through the pipeline for alkaline washing, and the impurities such as tar, naphthalene, ammonia and H2S in the tail gas are removed after pickling and alkaline washing, and then sent to the coke oven main pipe through the induced draft fan;

[0019] 3) Part of the coke oven flue gas treated by the desulfurization and denitration system is transported to the coke oven main pipe through the pipeline;

[0020] 4) Ammonia-containing tail gas and coke oven flue gas are combined in the main pipe and sent to the original coke oven combustion-supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com