Precision integrated treatment management system for electroplating wastewater and its realization method

A technology of electroplating wastewater and management system, which is applied in metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of difficult control of components, inability to automatically feedback information, independent monitoring and control of treatment process, control of treatment, etc. , to achieve the effect of improving the living environment and urban ecological environment, improving the quality of surface water, and reducing potential dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

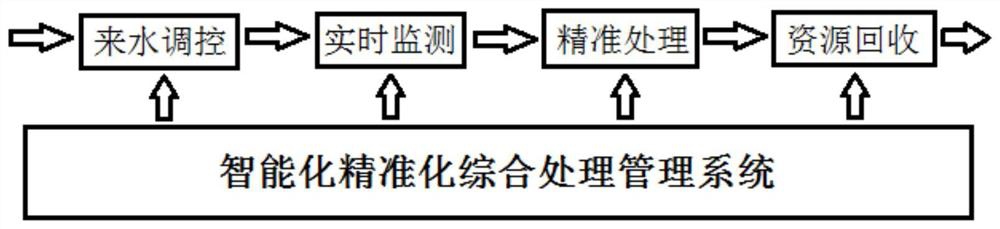

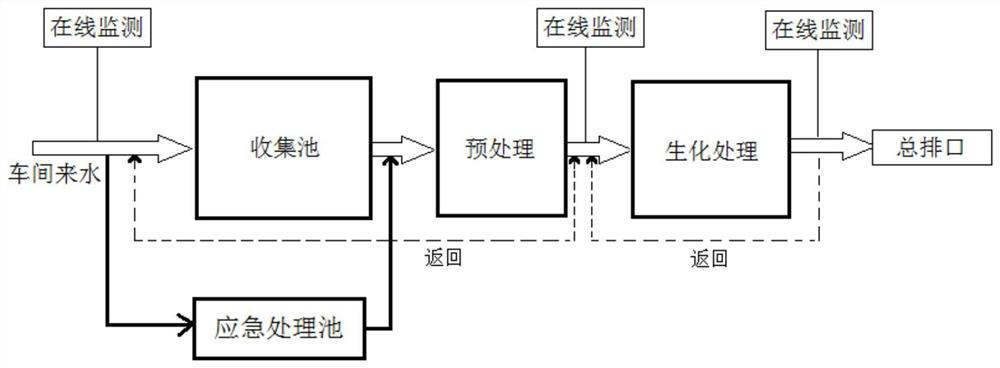

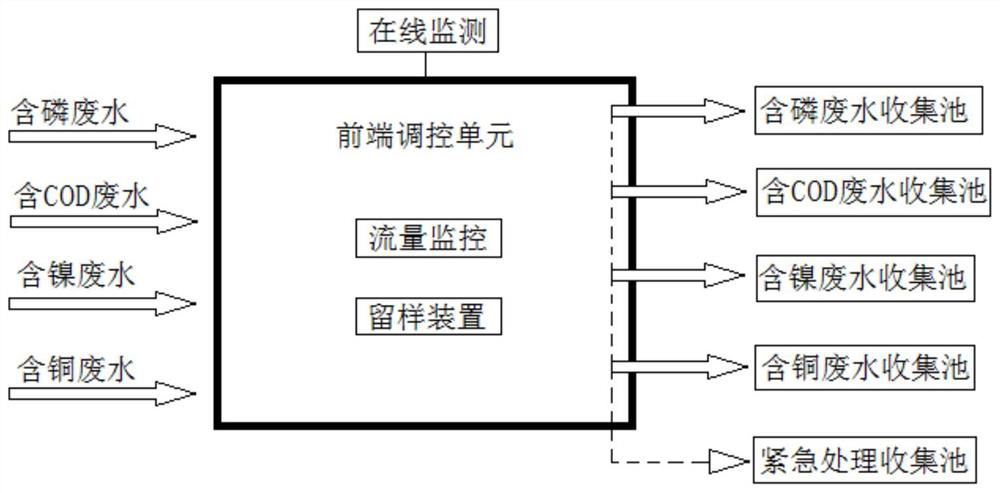

[0038] see figure 1 , figure 2 , image 3 , Figure 4 , the present invention designs electroplating wastewater precision comprehensive treatment management system in order to realize the classified collection and classified treatment of electroplating wastewater discharged from the factory, including:

[0039] A front-end control unit, which contains multiple online monitoring modules and collection pools for various types of wastewater. Among them, multiple online monitoring modules are responsible for detecting the water quality parameters of the electroplating wastewater discharged from each workshop in the factory area, and determining the type of electroplating wastewater; the collection pool is responsible for Collect the corresponding type of electroplating wastewater that does not exceed the standard;

[0040] A wastewater treatment unit, including pretreatment pools and biochemical pools for various types of wastewater. The pretreatment pool is responsible for co...

Embodiment 2

[0052] In the present invention, see Figure 11 , the pretreatment pool is equipped with a dosing unit, and the dosing unit is responsible for receiving the dosing instruction from the control terminal for dosing; see Figure 11 , the dosing unit comprises a dosing barrel 6, an agitator 7, a liquid level gauge 8, a metering pump 9, a flow meter 10, and a solenoid valve 11, wherein the dosing barrel 6 is provided with an agitator 7, a liquid level gauge 8, and stirring The device 7 is driven by a motor to stir the stirring rod, and the motor can be opened manually or remotely through the control terminal; The valve 11 is set in the middle of the dosing pipe, the solenoid valve 11 and the metering pump 9 are opened and closed by the control terminal; the liquid level meter 8 and the flow meter 10 send liquid level information and flow information to the control terminal in real time, so that the medicine can be replenished in time;

[0053] Wherein, according to the type of was...

Embodiment 3

[0056] see figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 , the present invention also provides the realization method of electroplating waste water precise comprehensive treatment management system, specifically comprises the following steps:

[0057] Step 1: Open the discharge pipes of electroplating wastewater in each workshop, the sample retention unit retains wastewater samples, the online monitoring module detects in real time, obtains the parameters of wastewater quality, and determines the type of wastewater according to the characteristic pollutants of electroplating wastewater; for wastewater exceeding the standard, the control terminal controls the bee After the buzzer alerts, it will be diverted to the emergency collection pool; the waste water that does not exceed the standard will be diverted to the corresponding collection pool according to the water quality type, and the control terminal will control the opening of the back-end control valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com