Preparation method and application of Au-coated Pd core-shell structure ultra-long nanowire in water phase

A core-shell structure and nanowire technology is applied in the field of preparation of bimetallic nanomaterials, which can solve problems such as increased cost and air pollution, and achieve the effects of green reaction, low energy consumption, and uniform appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

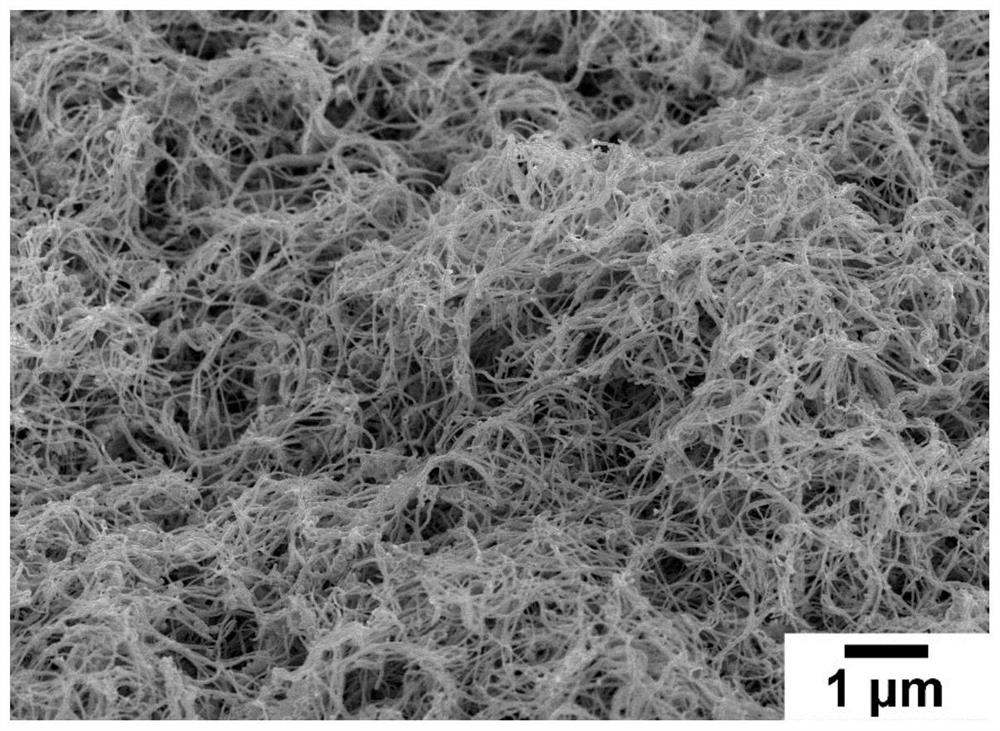

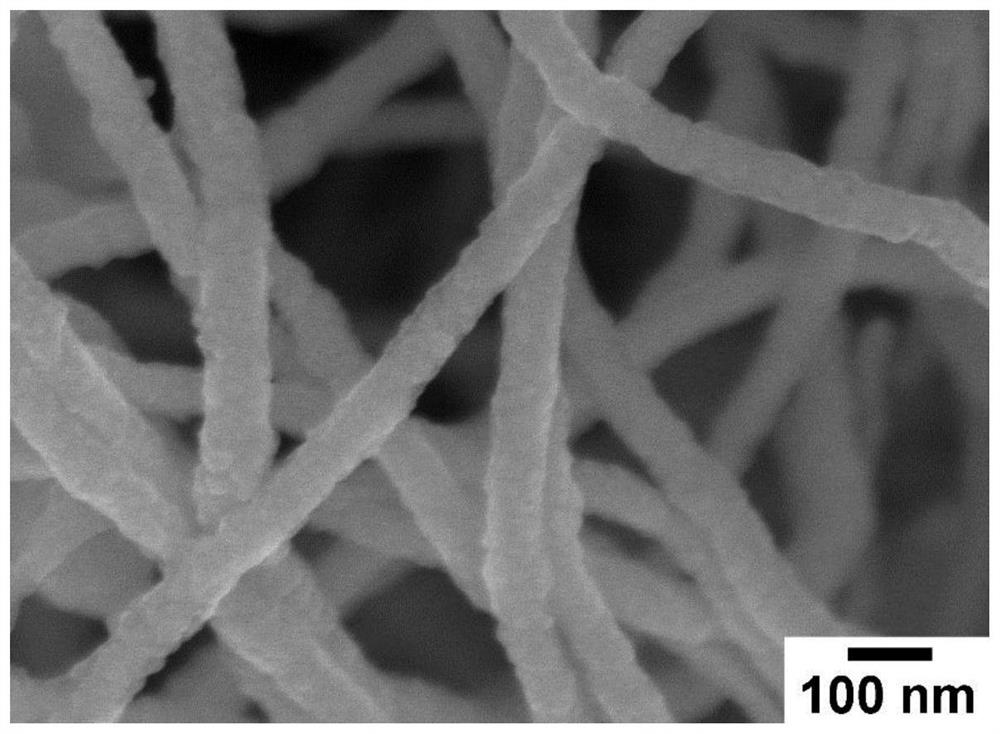

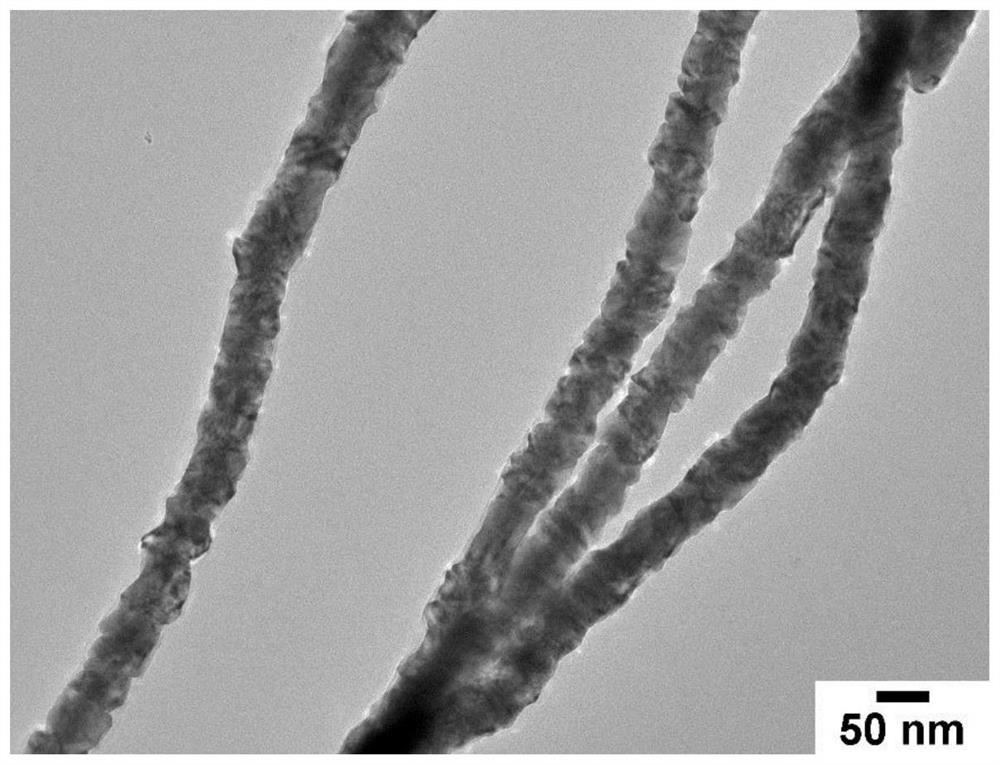

[0030] A preparation method of Au@Pd core-shell structure ultra-long nanowires in aqueous phase, comprising the following steps:

[0031] Step 1, take by weighing a certain amount of 1-hexadecyl-3-methylimidazolium chloride ([C 16 mim]Cl) is mixed with the ionic liquid aqueous solution that molar concentration is 0.025-0.10M, standby;

[0032] Step 2, get 5mL of the ionic liquid aqueous solution in step 1 and add it to the round-bottomed flask;

[0033] Step 3, in the round-bottomed flask of step 2, the amount of material added earlier is 0.002-0.004mmol of HAuCl 4 , and then add the amount of Na of 0.001-0.003 mmol 2 PdCl 4 , and finally add KBr with an amount of 0.004-0.005 mmol; fully mix the above reactants to obtain a reaction solution;

[0034] Step 4. Weigh ascorbic acid, add distilled water, prepare an ascorbic acid aqueous solution with a molar concentration of 0.1-0.2M, take a certain volume of ascorbic acid aqueous solution and add it to the reaction solution ob...

Embodiment 1

[0037] 1) Weigh a certain amount of ionic liquid [C 16 mim]Cl, make up to 100 mL, and prepare [C with a molar concentration of 0.10 M 16 mim]Cl aqueous solution;

[0038] 2) Take 5mL of [C in step 1) 16 mim]Cl aqueous solution into a round-bottomed flask;

[0039] 3) In the round-bottomed flask of step 2), first add HAuCl with an amount of material of 0.003 mmol 4 , and then add the amount of the substance is 0.002mmol of Na 2 PdCl 4 , and finally add KBr with an amount of 0.004 mmol; fully mix the above reactants to obtain a reaction solution;

[0040] 4) Weigh ascorbic acid, add distilled water, prepare an aqueous solution of ascorbic acid with a molar concentration of 0.1M, and add 0.5 mL to the reaction solution in step 3); gently shake the round-bottomed flask to mix the reaction solution uniformly, then keep it at 30°C Set the reaction for 10h to prepare the reaction mixture;

[0041] 5) Centrifuge the reaction mixture obtained in step 4), discard the supernatant ...

Embodiment 2

[0043] 1) Weigh a certain amount of ionic liquid [C 16 mim]Cl, make up to 100mL, and prepare [C with a molar concentration of 0.080M 16 mim]Cl aqueous solution;

[0044] 2) Take 5 mL of [C in step 1) 16 mim]Cl aqueous solution into a round-bottomed flask;

[0045] 3) In the round-bottomed flask of step 2), first add HAuCl with an amount of material of 0.004 mmol 4 , and then add the amount of the substance is 0.001mmol of Na 2 PdCl 4 , and finally add KBr with an amount of 0.005 mmol; fully mix the above reactants to obtain a reaction solution;

[0046] 4) Weigh ascorbic acid, add distilled water, prepare an aqueous solution of ascorbic acid with a molar concentration of 0.2M, and add 0.5 mL to the reaction solution in step 3); gently shake the round-bottomed flask to mix the reaction solution uniformly, then keep it at 30°C Set the reaction for 9h to prepare the reaction mixture;

[0047] 5) Centrifuge the reaction mixture obtained in step 4), discard the supernatant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com