Smooth brand switching method for vapor phase method polyethylene process

A technology of brand switching and gas phase method, applied in chemical instruments and methods, control/regulation processes, chemical/physical/physical chemical processes, etc., can solve problems such as temperature fluctuations in reactors, reduce energy consumption, maintain stable temperature, Reduce the effect of excessive intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the protection scope of the present invention. In the following examples, the operation methods without specific conditions are usually in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

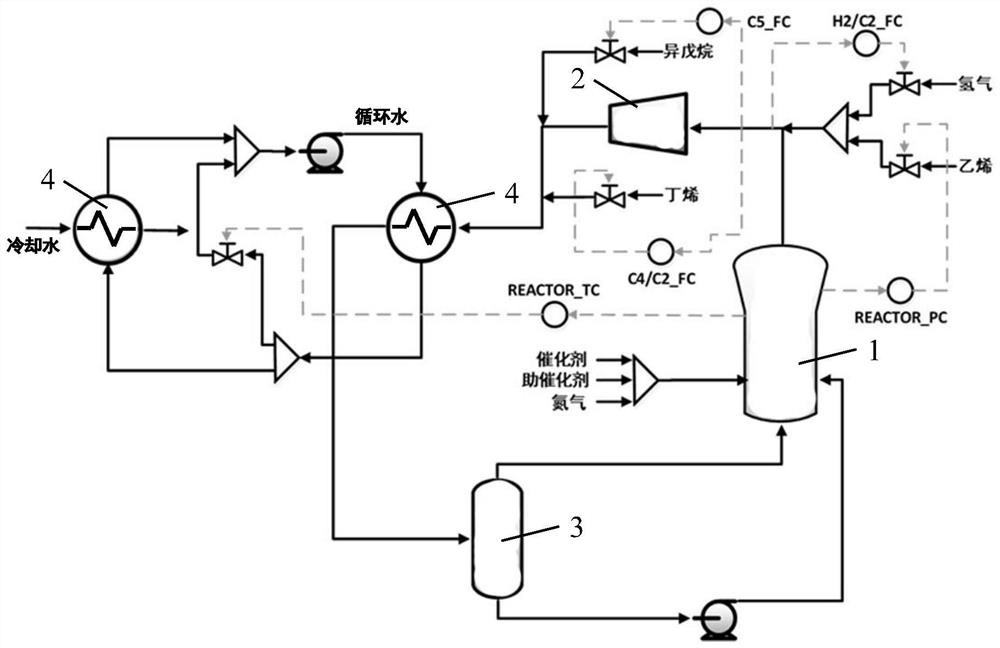

[0034] Gas-phase polyethylene process reaction units and processes such as figure 1 As shown, it mainly includes a reactor 1, a compressor 2, a gas-liquid separator 3, two heat exchangers 4 and other devices. In the polymerization unit, Reactor 1 is a key component of the process. Reactor 1 of this process is a fluidized bed reactor. The high flow rate circulating gas blows the catalyst particles into a fluidized state, and ethylene, hydrogen and comonomers (such as butene, hexene, etc.) u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com