Vertically arranged carbon fiber-polycarbonate heat-conducting composite material and preparation method thereof

A thermally conductive composite material, polycarbonate technology, applied in coatings, devices for coating liquids on surfaces, etc., can solve problems such as inability to have high thermal conductivity electronic devices, and achieve low equipment requirements, good product performance, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

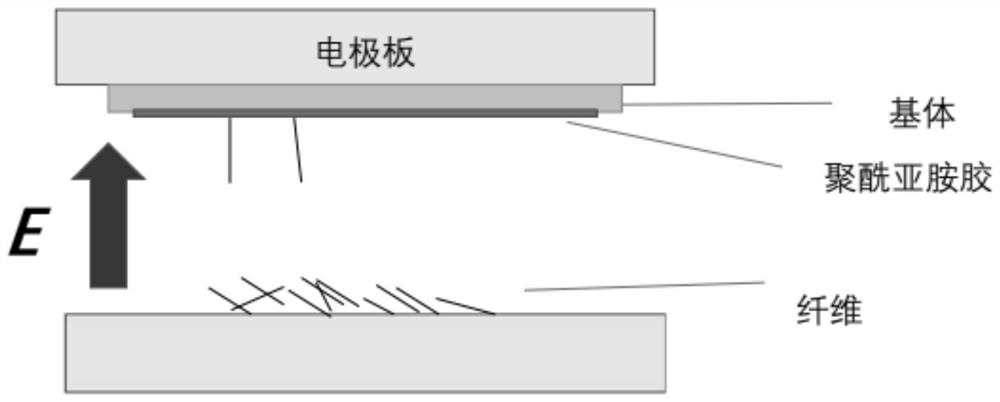

[0025] Preparation of Vertically Aligned Carbon Fiber / Polycarbonate Composites:

[0026] Taking mesophase pitch-based carbon fibers and graphitizing them at 3000℃, high thermal conductivity carbon fibers were obtained, and their thermal conductivity was 900W·m -1 ·K -1 . Weigh 0.5 g of the cut fiber, and the fiber length is 1 mm. The fibers were evenly distributed on the circular iron sheet through the screen, and the electric field distance was set to 6 cm.

[0027] Paste a layer of polyimide glue on the upper end of the electrostatic flocking instrument, place the metal disc with fibers on the lower end of the instrument, and close the hatch. Turn on the instrument, adjust the voltage of the electric field to 20KV, and the fibers are adsorbed on the polyimide glue under the action of the electric field, showing a state of vertical arrangement, repeating several times until the fibers are covered with the entire polyimide glue.

[0028] 5g of polycarbonate particles were ...

Embodiment 2

[0030] The mesophase pitch-based carbon fiber was taken and graphitized at 3000 °C to obtain a high thermal conductivity carbon fiber with a thermal conductivity of 900 W m -1 •K -1 . Weigh 0.5 g of the cut fiber, and the fiber length is 1 mm. The fibers were evenly distributed on the circular iron sheet through the screen, and the electric field distance was set to 9 cm.

[0031] Paste a layer of polyimide glue on the upper end of the electrostatic flocking instrument, place the metal disc with fibers on the lower end of the instrument, and close the hatch. Turn on the instrument, adjust the voltage of the electric field to 20KV, and the fibers are adsorbed on the polyimide glue under the action of the electric field, showing a state of vertical arrangement, repeating several times until the fibers are covered with the entire polyimide glue.

[0032] 5 g of polycarbonate particles were dissolved in 20 g of tetrahydrofuran to form a mixed liquid with a certain viscosity. T...

Embodiment 3

[0034] Taking mesophase pitch-based carbon fibers and graphitizing them at 3000℃, high thermal conductivity carbon fibers were obtained, and their thermal conductivity was 900W·m -1 ·K -1 . Weigh 0.5 g of the cut fiber, and the fiber length is 1 mm. The fibers were evenly distributed on the circular iron sheet through the screen, and the electric field distance was set to 12 cm.

[0035] Paste a layer of polyimide glue on the upper end of the electrostatic flocking instrument, place the metal disc with fibers on the lower end of the instrument, and close the hatch. Turn on the instrument, adjust the voltage of the electric field to 20KV, and the fibers are adsorbed on the polyimide glue under the action of the electric field, showing a state of vertical arrangement, repeating several times until the fibers are covered with the entire polyimide glue.

[0036] 5 g of polycarbonate particles were dissolved in 20 g of tetrahydrofuran, and the polycarbonate particles were dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com