System for improving yield of organic compound cracking liquid phase product and working method thereof

A technology of organic compounds and cracking liquid, which is applied in the preparation of liquid hydrocarbon mixture, the treatment of cracking process with only multi-stage series, combustion method, etc., can solve the problem of low yield of cracked oil, and increase the output of cracked oil , the effect of fast heat transfer and increased reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] like Image 6 As shown, the embodiment of the present invention provides a system for improving the yield of organic compound cracking liquid phase products, comprising a heat exchanger 39 and a main pipeline 40, the heat exchanger 39 is connected with a cracking reactor 38 through the main pipeline 40, and the cracking reactor 38 The No. 1 solenoid valve 37 is connected through the main pipeline 40, the No. 1 solenoid valve 37 is connected with the No. 5 pressure gauge 36 through the main pipeline 40, and the No. 5 pressure gauge 36 is connected with the No. 2 pressure regulating valve 35 through the main pipeline 40, and the No. 2 pressure regulating valve The valve 35 is connected to the No. 4 pressure gauge 34 through the main pipeline 40, the No. 4 pressure gauge 34 is connected to the FM Roots fan 33 and the No. 2 solenoid valve 41 through the main pipeline 40, and the No. 2 solenoid valve 41 is connected to the main pipeline 40. The condensable gas buffer device ...

Embodiment 2

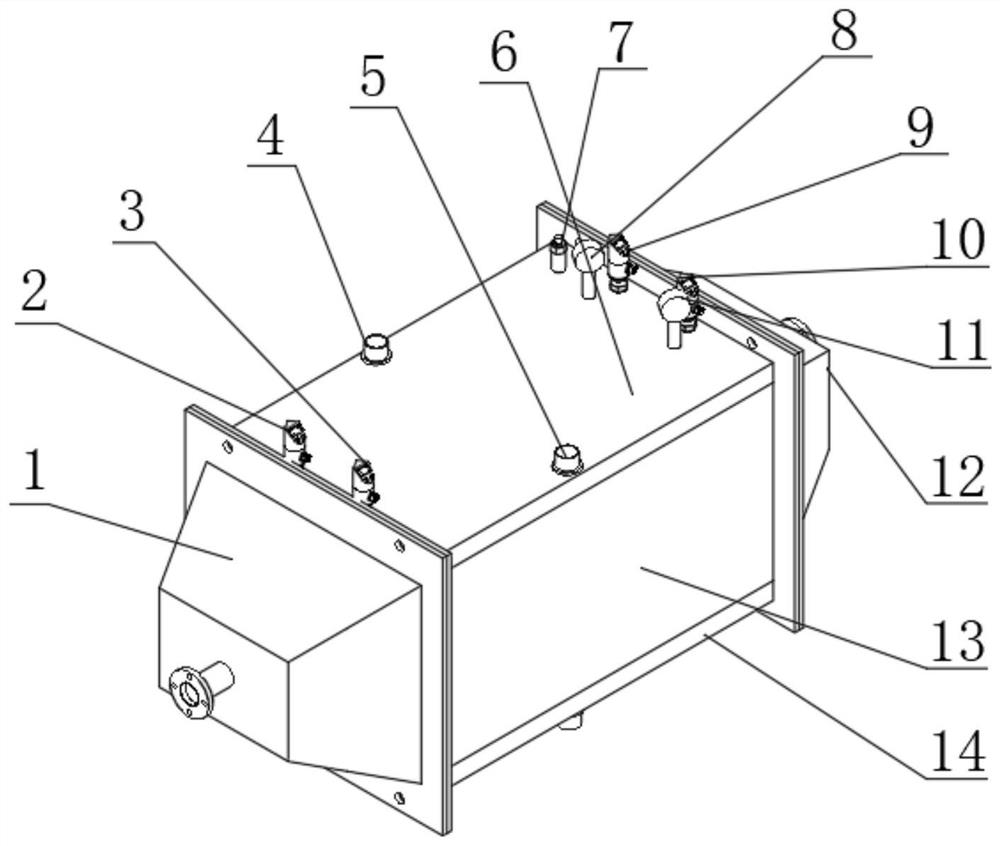

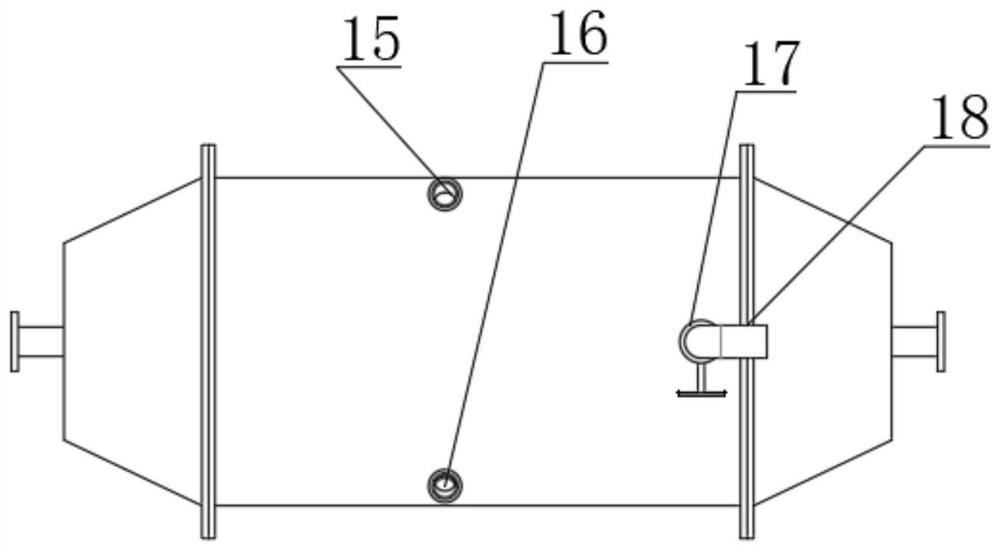

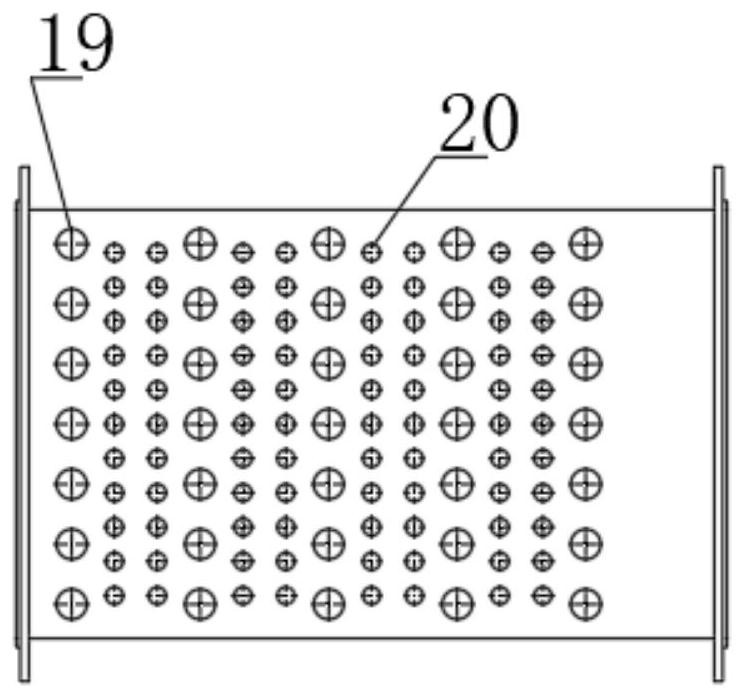

[0050] like Figure 1-5 As shown in the figure, the embodiment of the present invention provides a system for improving the yield of liquid phase products of organic compound cracking. The two-carbon olefin liquefaction device 30 includes a box body 13. The left end cover 1 is fixedly connected to the left side of the box body 13, and the right side of the box body 13 is fixed. A right end cover 12 is connected, a first temperature sensor 2 is penetrated and fixedly connected to the top left middle of the box body 13 at the rear end position, and a first pressure sensor 3 is penetrated and fixedly connected to the front end position of the top left middle of the box body 13 . The middle position of the top rear end of the box body 13 runs through and is provided with a large aperture water inlet 4, the middle position of the front end of the box body 13 runs through and is provided with a small aperture water inlet 5, the top of the box body 13 is fixedly connected with an uppe...

Embodiment 3

[0053] like Image 6 As shown, the embodiment of the present invention provides a system working method for improving the yield of organic compound cracking liquid phase product, comprising the following steps:

[0054] S1. Recovery of high-value chemical raw materials in non-condensable combustible gas

[0055] The macromolecular organic compound is put into the cracking reactor 38, and the compound is decomposed at high temperature to generate gas. After the gas is sent to the heat exchanger 39 through the main pipeline 40, the oil is condensed and collected, and the incombustible gas passes through the main pipeline 40 and passes through No. 1 in turn. One-way valve 26, No. 1 pressure gauge 27, No. 1 pressure regulating valve 28, No. 2 pressure gauge 29, two-carbon olefin liquefaction device 30, No. 3 pressure gauge 31 and No. 2 check valve 32, realize non-condensable combustible gas The No. 1 pressure regulating valve 28 is mainly used to adjust the pressure in the two-ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com