High-grade non-oriented electrical steel and preparation method thereof

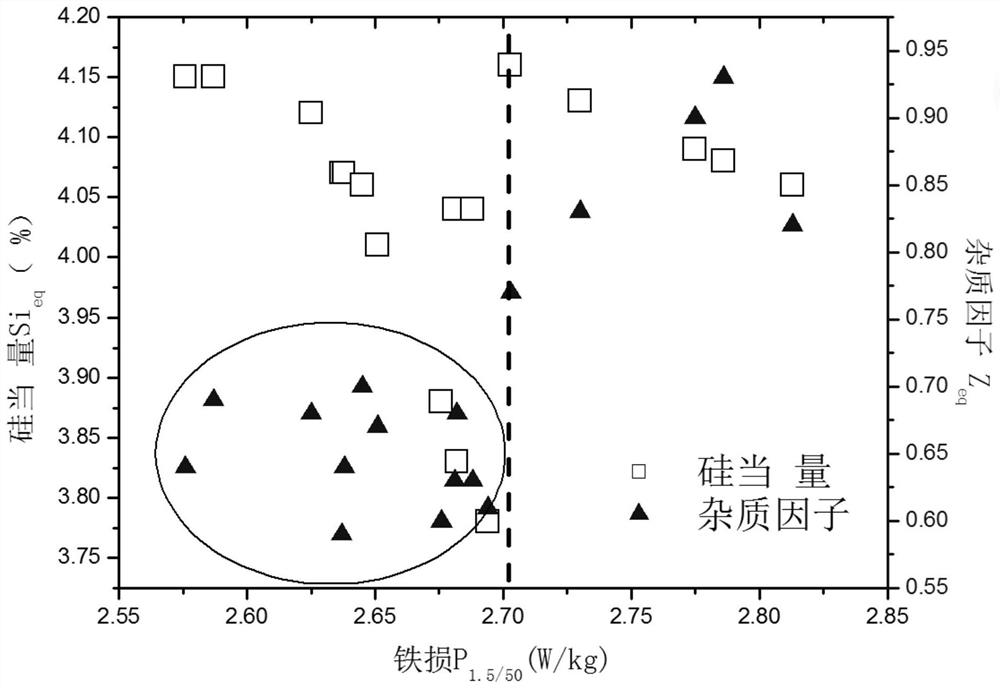

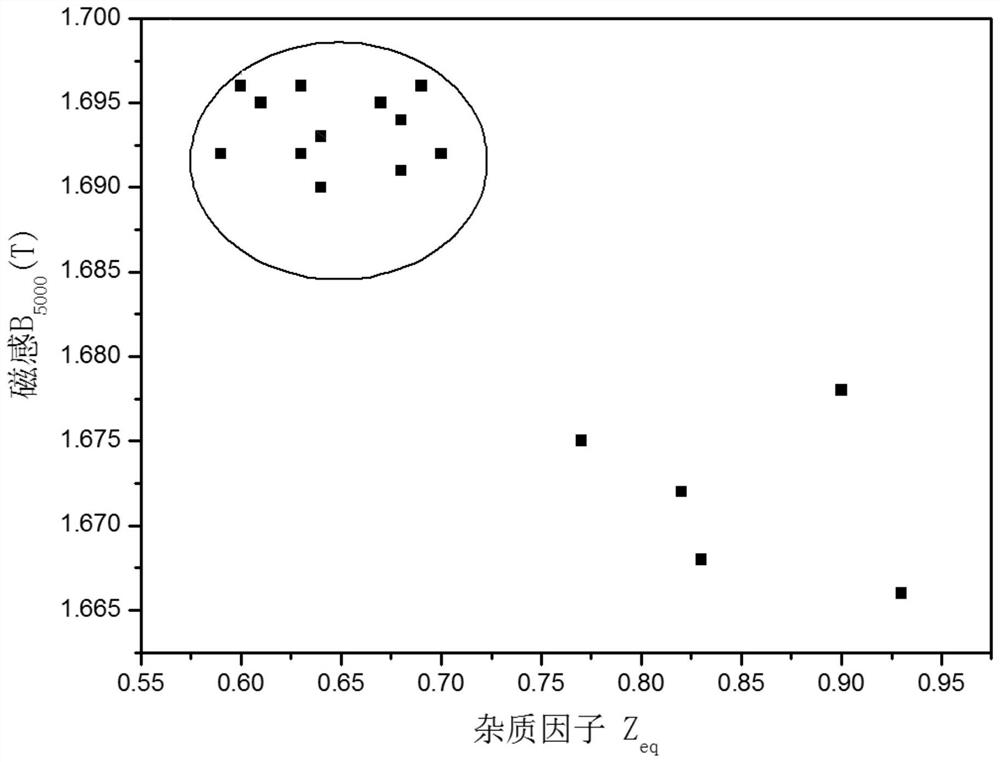

A technology of grain-oriented electrical steel and high grade, applied in the field of electrical steel, which can solve the problems of high iron loss and low magnetic induction of electrical steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

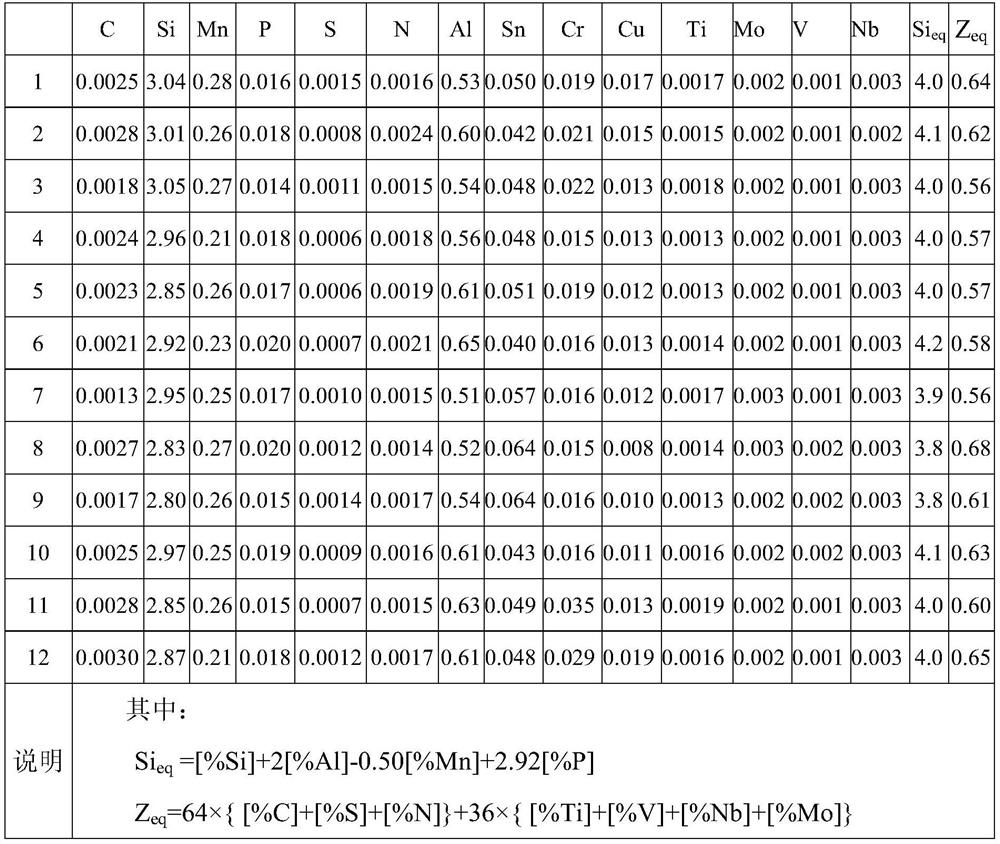

Examples

Embodiment

[0063] The present embodiment provides a kind of preparation method of high-grade non-oriented electrical steel, and its concrete steps are as follows:

[0064] 1) Carry out hot metal pretreatment, including desulfurization and slag removal: it is required that the molten iron S≤0.030% and Ti≤0.050% before desulfurization, the slag removal after desulfurization is clean, and the molten iron after desulfurization is controlled to S≤0.0015%;

[0065] 2) Carry out converter smelting: it is required to add low-sulfur (S≤0.010%) scrap steel, and use low-sulfur (S≤0.020%) steelmaking auxiliary materials, and control the end point of the converter to be C: 0.020~0.040%, S≤0.0030%, P≤ 0.018%, [O]≤750ppm, control ladle slag thickness≤60mm when tapping;

[0066] 3) Deoxidize and alloy the molten steel after smelting, and then perform secondary desulfurization, and finally make C≤0.0030wt%, S≤0.0015wt%, Ti≤0.0020wt% in the molten steel, and the vacuum degree is required to be less than 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com