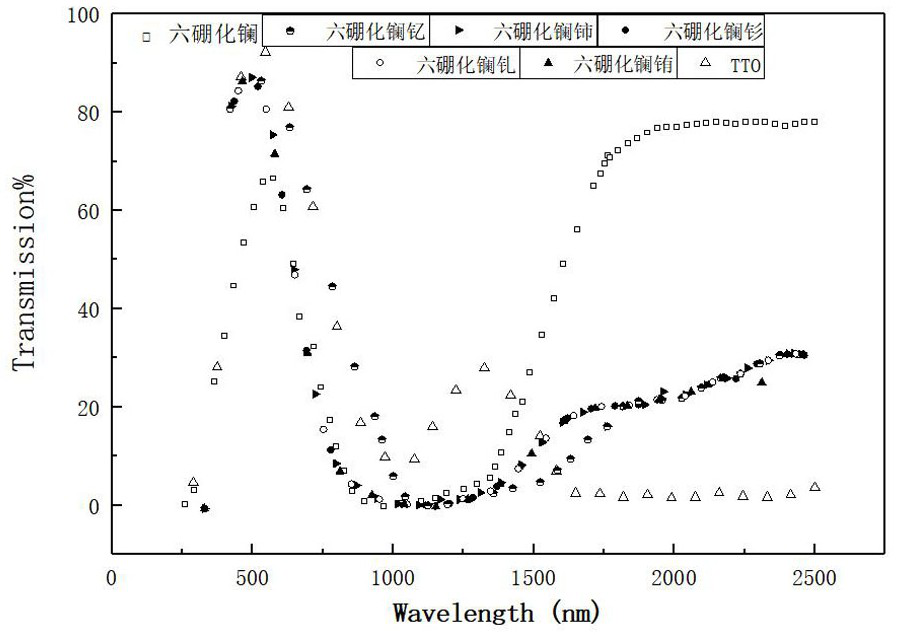

Rare-earth-based infrared heating thermal fabric as well as preparation method and application thereof

A rare earth-based, infrared technology, applied in the field of textile fabrics, can solve the problems of inconvenient washing and inability to wash with water, and achieve the effect of simple structure and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

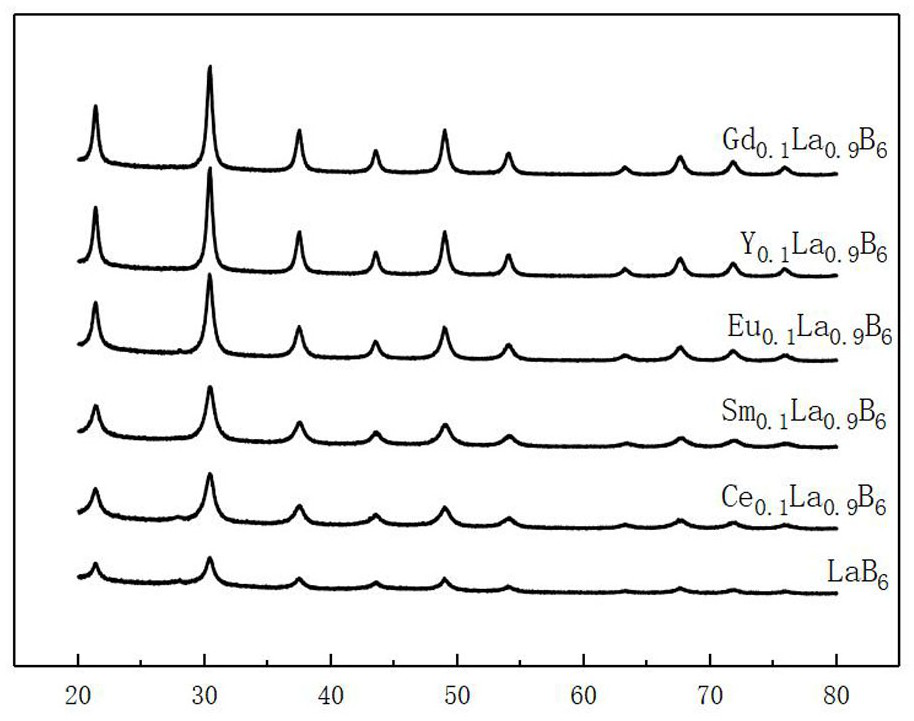

[0043] Example 1 Preparation of Gd 0.1 La 0.9 B 6 Powder, including the following steps:

[0044] (1) Press Gd:La:B:Na:SiO 2 The molar ratio is the ratio of 0.1:0.9:6:24:12, respectively weighing Gd 2 (CO 3 ) 3 495g, La 2 (CO 3 ) 3 2060g, B 2 O 3 2089g, Na 552g, SiO 2 720g, all the raw materials were put into the autoclave, 12 moles of hydrogen were introduced, heated to 320°C, and stirred for two hours. The obtained product was extracted with deionized water and separated into layers, the precipitated part was filtered and washed with water for 5 times, and the obtained product was dried at 110° C. for 5 hours. After drying, the product and 6 kg of deionized water were loaded into a sand mill and ground for 8 hours. After testing, the particle size of the slurry was 500-700 nanometers. The slurry was first spray granulated and dried, and the particle size of the obtained powder was 700 nanometers. -800 nm. The 700-800 nanometer powder is subjected to the secon...

Embodiment 2

[0047] Example 2 Preparation of Ce 0.1 La 0.9 B 6 Powder, as Ce:La:B:Na:SiO 2 The molar ratio is 0.1:0.9:6:24:12, respectively weighing Ce(NO 3 ) 3 326g, La 2 (CO 3 ) 3 2060g, B 2 O 3 2089g, Na 552g, SiO 2 720g, the remaining steps are the same as 1.1 to prepare Gd 0.1 La 0.9 B 6 The steps for powder are the same.

Embodiment 3

[0048] Example 3 Preparation of Sm 0.1 La 0.9 B 6 Powder, according to Sm:La:B:Na:SiO 2 The molar ratio is 0.1:0.9:6:24:12, respectively weigh Sm(NO 3 ) 3 336g, La 2 (CO 3 ) 3 2060g, B 2 O 3 2089g, Na 552g, SiO 2 720g, the remaining steps are the same as 1.1 to prepare Gd 0.1 La 0.9 B 6 The steps for powder are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com