Nozzle for reducing nitrogen oxide emission of aluminum oxide roasting furnace

A nitrogen oxide and roaster technology, applied in the direction of burner, combustion type, combustion method, etc., can solve the problems of high temperature, small combustion area, long flame, etc., to reduce the temperature and oxygen concentration, and inhibit the formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

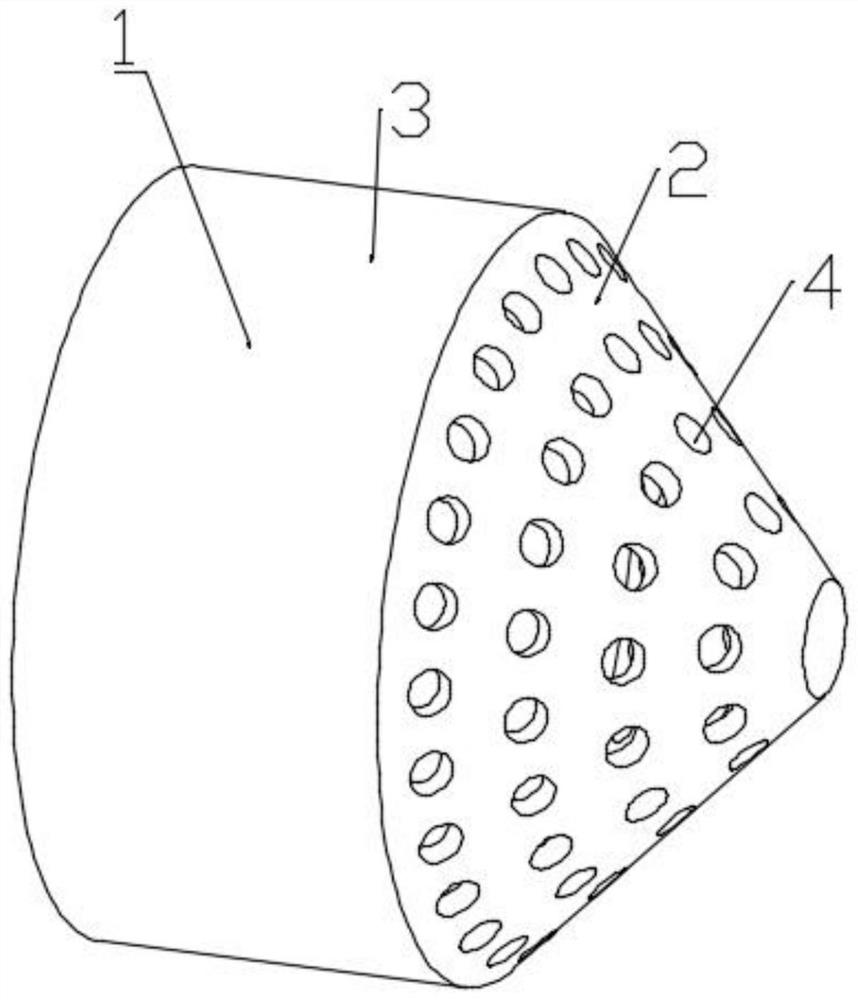

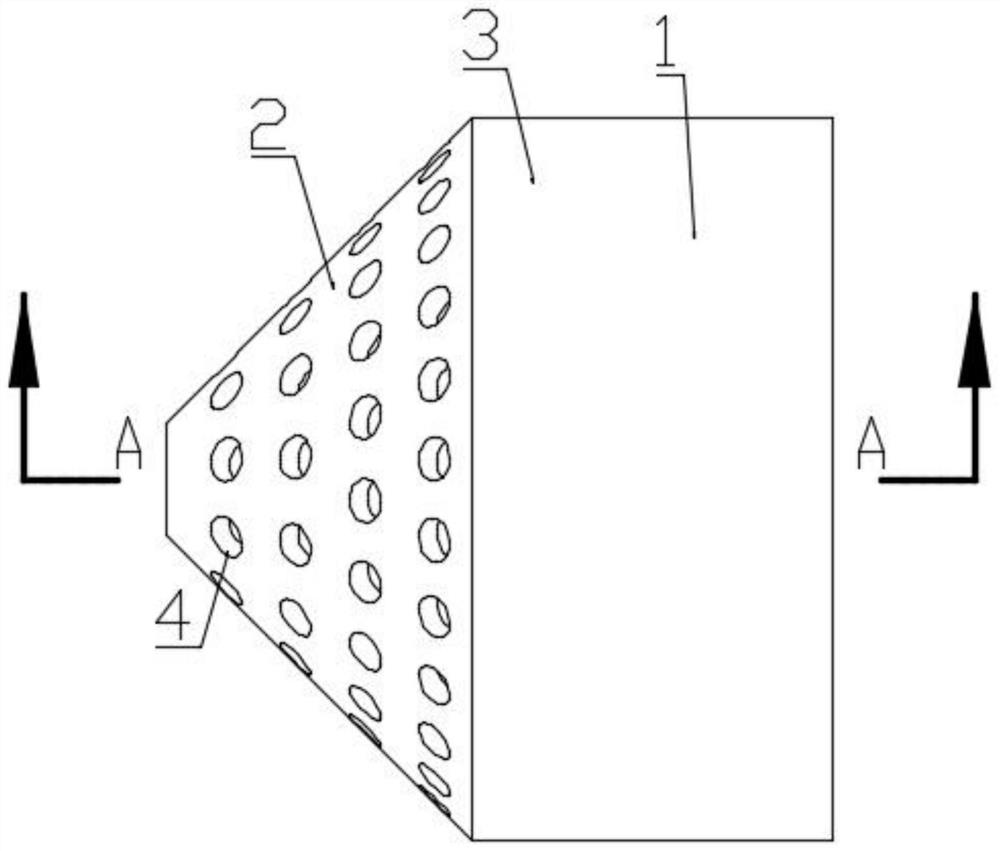

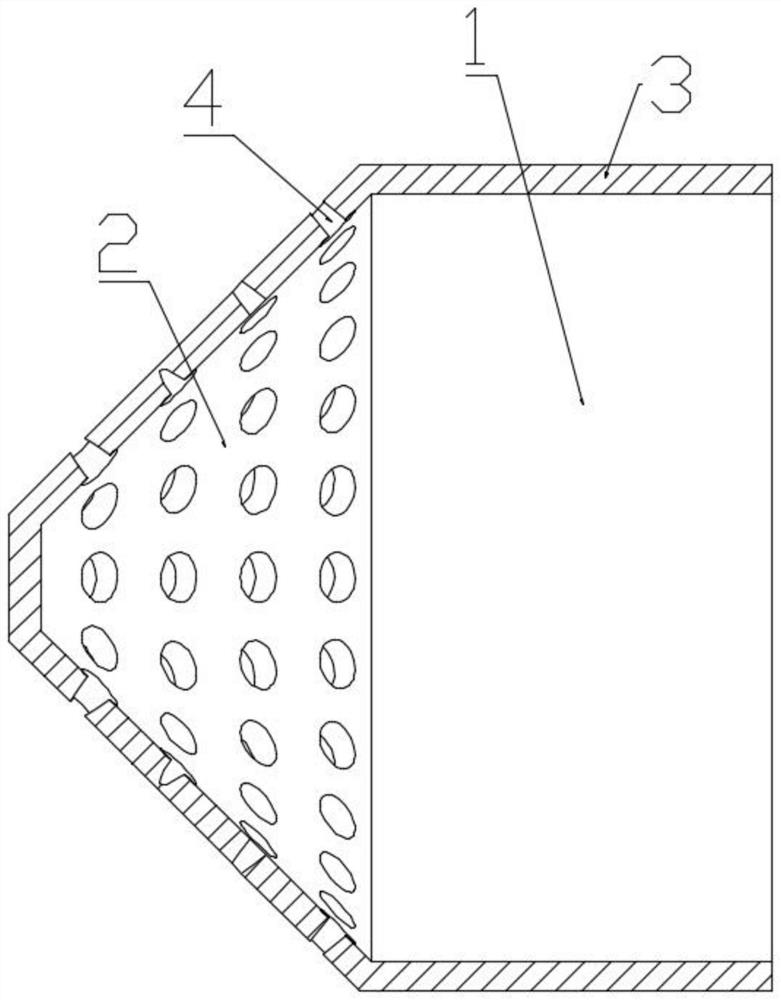

[0014] A nozzle of the present invention for reducing the emission of nitrogen oxides from an alumina roasting furnace will be further described in detail below with reference to the accompanying drawings.

[0015] With reference to the accompanying drawings, a nozzle for reducing the emission of nitrogen oxides from an alumina roasting furnace includes a nozzle body 1, which is composed of a front tip portion 2 and a rear round portion 3; the nozzle body 1 is Hollow shape, the rear part of the rear round part 3 is an opening, the front tip part 2 is provided with through holes 4 , and the through holes 4 are evenly arranged on the front tip part 2 .

[0016] The through holes 4 are arranged around the axial direction of the front tip 2 in the circumferential direction; the through holes 4 are arranged uniformly in the extension direction of the outer wall of the front tip 2 .

[0017] During the specific implementation of the present invention, through holes 4 are provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com