Cold treatment device and processing method of neodymium-iron-boron magnet

A NdFeB, cold treatment technology, used in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the loss of wide hysteresis loop, high coercive force and high remanence, poor temperature characteristics, grain and grain boundary phase destruction, to achieve wide hysteresis loop, increase magnetism, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

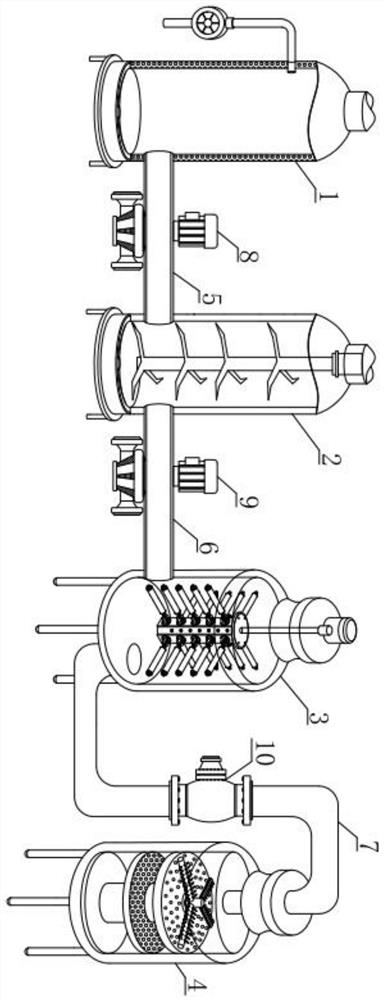

[0038] A method for implementing a cold treatment device for a NdFeB magnet, comprising the following steps:

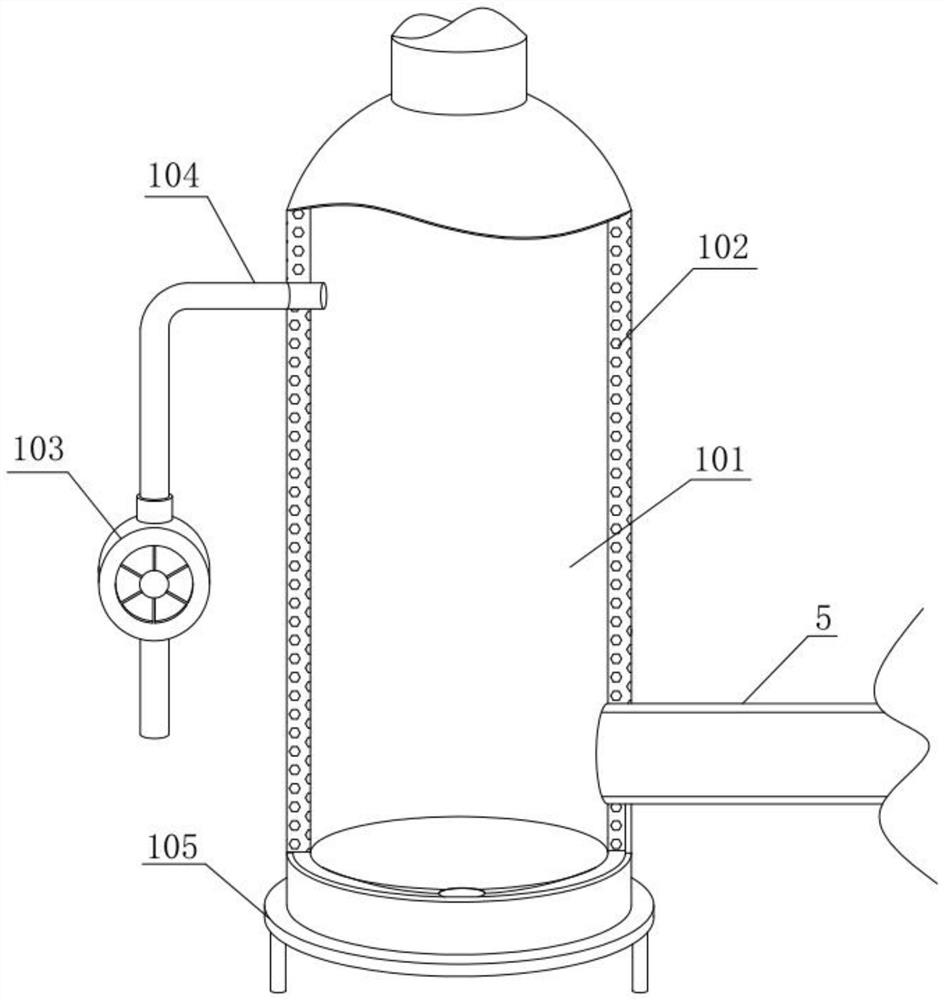

[0039] In the first step, the untreated NdFeB magnets with a magnetic flux of 3860G are put into the belt-slung furnace 1, then the evacuation pump 103 is started, and the oxygen in the inner cavity 101 of the belt-slung furnace is evacuated through the evacuation pipe 104, while preheating The layer 102 continuously heats the NdFeB magnets in the inner cavity 101 of the belt slinging furnace, and after heating, the NdFeB magnets are sent to the stirring furnace 2 through the first transport pipe 5;

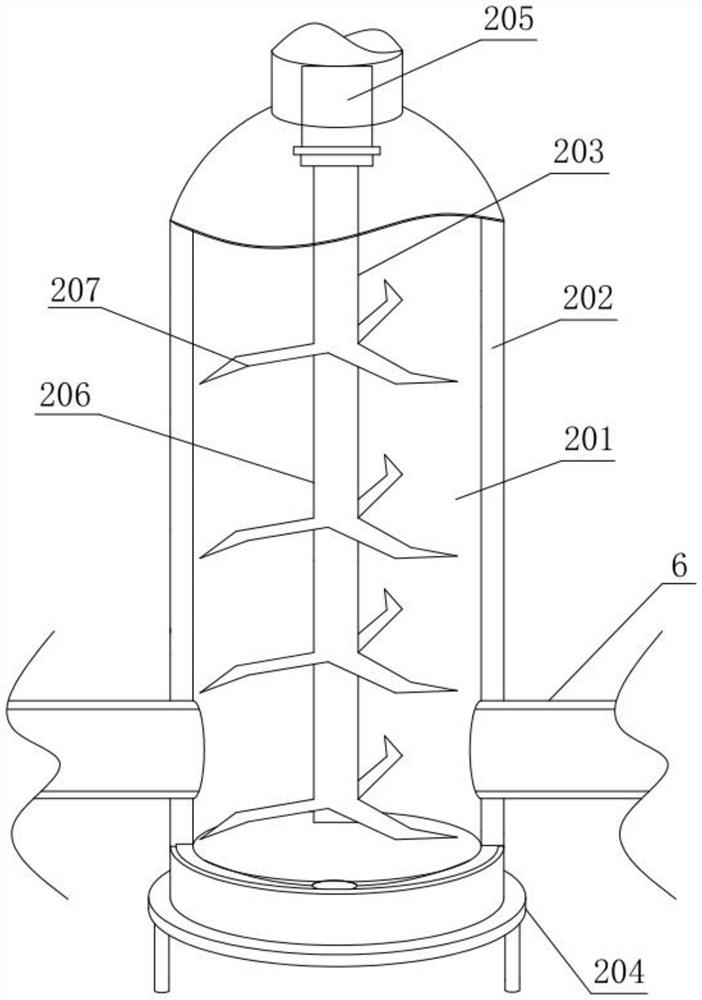

[0040] The second step is to start the stirring device 203 after sending it to the stirring furnace 2. The stirring blade 207 stirs the NdFeB magnet through the stirring shaft 206, and the stirring time is 1.5h. At the same time, the cooling layer 202 can continuously cool the NdFeB magnet. , the NdFeB magnets are transported to the soaking furnace 3 through the second t...

Embodiment 2

[0044] A method for implementing a cold treatment device for a NdFeB magnet, comprising the following steps:

[0045] The first step is to put the untreated NdFeB magnet with a magnetic flux of 3950G into the belt-slung furnace 1, then start the evacuation pump 103, and evacuate the oxygen in the inner cavity 101 of the belt-slung furnace through the evacuation pipe 104, while preheating The layer 102 continuously heats the NdFeB magnets in the inner cavity 101 of the belt slinging furnace, and after heating, the NdFeB magnets are sent to the stirring furnace 2 through the first transport pipe 5;

[0046] The second step is to start the stirring device 203 after sending it to the stirring furnace 2. The stirring blade 207 stirs the NdFeB magnet through the stirring shaft 206, and the stirring time is 1.5h. At the same time, the cooling layer 202 can continuously cool the NdFeB magnet. , the NdFeB magnets are transported to the soaking furnace 3 through the second transport pip...

Embodiment 3

[0050] A method for implementing a cold treatment device for a NdFeB magnet, comprising the following steps:

[0051] In the first step, the untreated NdFeB magnet with a magnetic flux of 4180G is put into the belt-slung furnace 1, then the evacuation pump 103 is started, and the oxygen in the inner cavity 101 of the belt-slung furnace is evacuated through the evacuation pipe 104, and the preheating is performed at the same time. The layer 102 continuously heats the NdFeB magnets in the inner cavity 101 of the belt slinging furnace, and after heating, the NdFeB magnets are sent to the stirring furnace 2 through the first transport pipe 5;

[0052] The second step is to start the stirring device 203 after sending it to the stirring furnace 2. The stirring blade 207 stirs the NdFeB magnet through the stirring shaft 206, and the stirring time is 1.5h. At the same time, the cooling layer 202 can continuously cool the NdFeB magnet. , the NdFeB magnets are transported to the soaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com