Single-chamber MFC reactor with ultra-miniature air cathode and manufacturing method

An air cathode and manufacturing method technology, applied in the fields of electrical components, climate sustainability, final product manufacturing, etc., can solve the problems of high cost of cathode reagents, long response time, high detection limit, etc., and achieve new configurations and structures The possibility of solving the effect of long response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

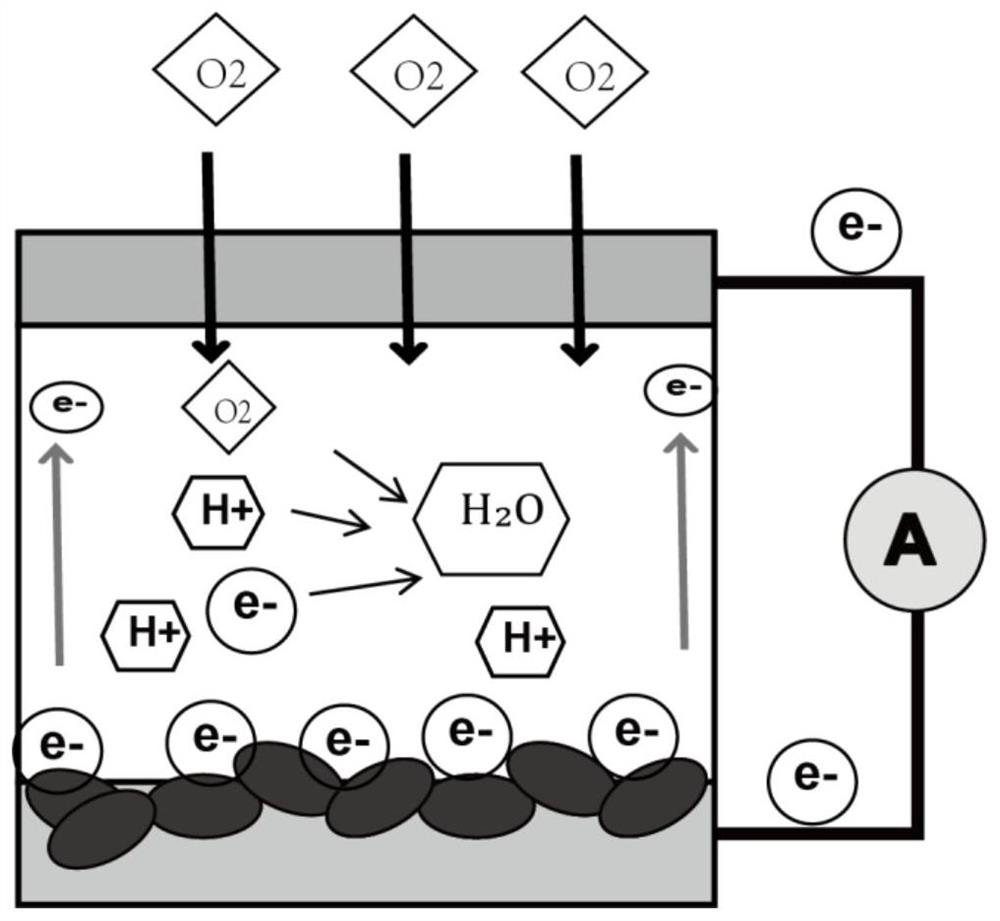

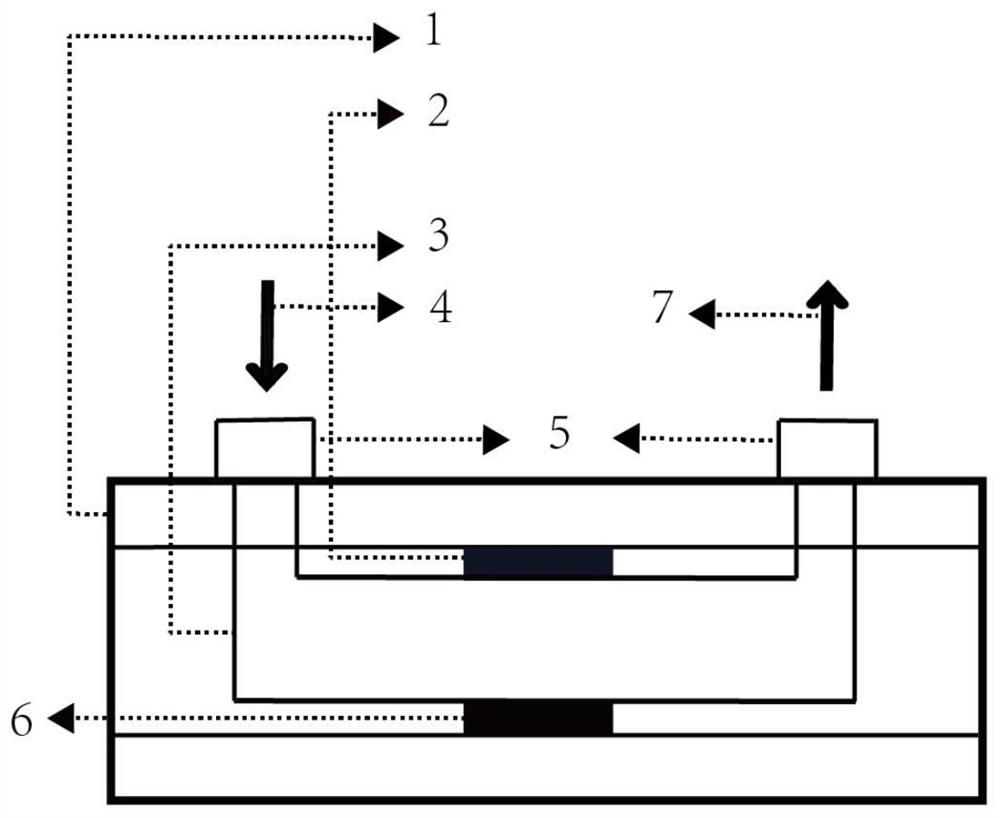

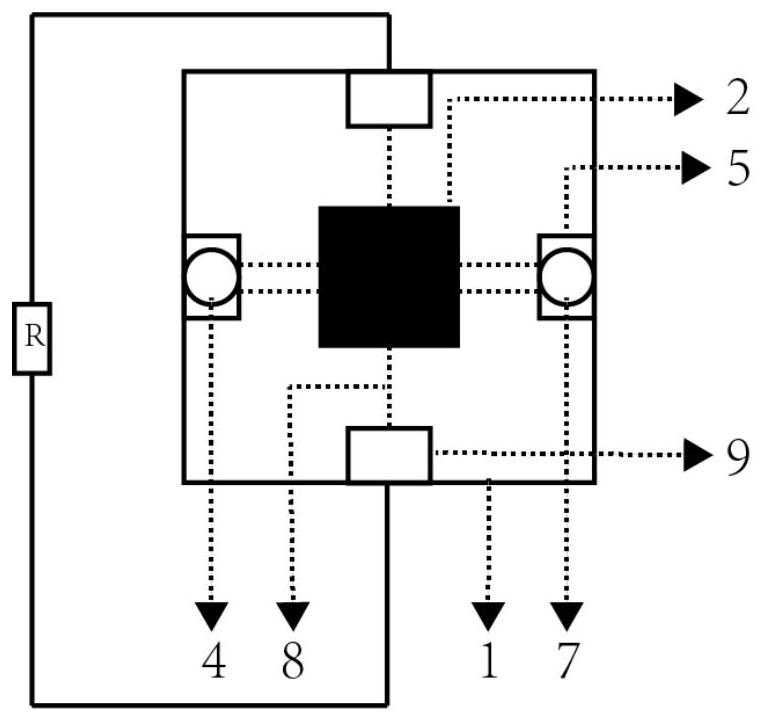

[0021] according to figure 1 Schematic diagram of the preparation of an ultra-miniature MFC reactor such as figure 2 and image 3 As shown, a single-chamber MFC structure of an ultra-miniature air cathode includes a carbon cloth anode 6, an air cathode 2, the cathode and anode electrons are connected to an external circuit through a carbon fiber wire 8, an anolyte injection pipe 4, a water outlet pipe 7, polydimethylformaldehyde Siloxane (PDMS) substrate 5 , copper tape 9 , and polyethylene terephthalic acid (PET) film 1 cut by xurographic technology constitute the chamber 3 of the reactor as the core components of the reactor. The air cathode 2 is composed of a polytetrafluoroethylene (PTFE) diffusion layer, a carbon base layer and a catalytic layer. In the actual working process of the reactor, the mixture of the water sample to be monitored and the nutrient solution is added into the microbial fuel cell chamber through the injection pipe 4, and reacts with the microorgan...

Embodiment 2

[0025] Optimize the structure of the ultra-micro single-chamber MFC, analyze the performance of the ultra-micro MFC under different chamber volumes, and set the chamber volumes to 125ul, 188ul and 250ul, corresponding to Figure 4 a,b,c in. It can be seen that different chamber volumes have a great influence on the performance of the ultra-micro MFC reactor in the present invention, and the optimal value of the chamber volume is 188ul.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com